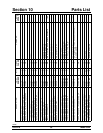

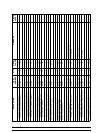

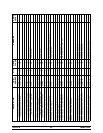

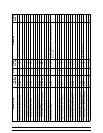

36

Model C302Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

6. Unable to remove the

drive shaft from the rear

shell bearing.

a. Rounded corners of hex

end of drive shaft, drive

coupling, or both.

a. Replace the drive shaft, or

call a service technician to

replace the direct drive

unit.

-- -- --

b. Lubrication of hex end of

drive shaft.

b. Do not lubricate the hex

end. If necessary, contact

a service technician for

removal.

19

7. Excessive loss of CO

2

. a. Leak in the CO

2

system. a. Contact a service

technician.

-- -- --

8. Leakage from rear drip

pan(s) into front drip tray.

a. Seal or o-ring on drive

shaft is worn, missing, or

incorrectly installed.

a. Replace or install correctly

on drive shaft.

19

b. Worn rear shell bearing. b. Contact a service

technician to replace rear

shell bearing.

-- -- --

9. Excessive mix leakage

from door spout.

a. Inadequate lubrication of

draw valve o-rings.

a. Lubricate properly.

21

b. Wrong type lubricant on

draw valve o-rings.

b. Use food grade lubricant

(example: Taylor Lube

HP).

19

c. Worn or missing draw

valve o-rings.

c. Replace or install o-rings

on draw valve.

21/ 37

10. Unable to adjust brix. a. Syrup lines need to be

cleaned and sanitized.

a. Clean and sanitize syrup

lines.

-- -- --

b. Blocked flow control. b. Contact a service

technician.

-- -- --

11. Lack of syrup being

supplied to machine.

a. Loss of CO

2

to propel

syrup.

a. Contact a service

technician.

-- -- --

b. Clogged or kinked syrup

lines.

b. Sanitize syrup lines

regularly. If kinked, repair

or replace.

-- -- --