48

Models C708 & C716Important: Operator Checklist

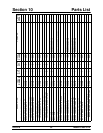

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

13. Excessive mix leakage

into the long dr ip pan.

a. The seal on drive shaft is

improperly lubricated or

worn.

a. Lubricate properly or

replace the seal.

26

b. The seal is installed

inside-out on the drive

shaft.

b. Install correctly.

26

c. Inadequate lubrication of

the drive shaft.

c. Lubricate properly.

26

d. The d rive shaft and beater

assembly work forward.

d. Call an authorized service

technician.

---

e. Worn rear shell bear ing. e. Call an authorized service

technician.

---

f. Gear box out of alignment. f. Call an authorized service

technician.

---

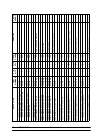

14. The drive shaft is stuck in

the drive coupling.

a. Mix and lubricant collected

in drive coupling.

a. Brush clean the r ear s hell

bearing area regularly.

42

b. Rounded corners of drive

shaft, drive coupling, or

both.

b. Call an authorized service

technician.

---

c. Gear box is out of

alignment.

c. Call an authorized service

technician.

---

15. The freezing cylinder

walls are scored.

a. Missing or worn front

bearing and beater s hoes.

a. Install or replace the front

bearing and beater s hoes.

27, 30

b. Broken freezer door baffle

rod.

b. Replace freezer door.

30

c. Broken beater pins. c. Replace beater assembly.

27

d. Beater assembly is bent. d. Replace beater assembly.

27

e. Gear box is out of

alignment.

e. Call an authorized service

technician.

---

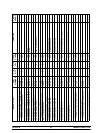

16. The product makes a

popping sound when

drawn.

a. Draw rate is set too fast. a. Adjust draw rate of 5 to 7

1/2 oz. (142 g. to 213 g.)

of product by weight in 10

seconds.

14

b. Pump assembled

incorrectly.

b. Assemble and lubricate

according to instructions

in this manual.

31

c. Freezing cylinder not

primed correctly.

c. Drain the freezing cylinder

and reprime the machine.

36