Page 7

For troubleshooting guides and further explanation of Maxitrol Series 14 and

44 electronic modulation gas control systems, refer to the Maxitrol literature

in the owner's envelope.

The Option AG30, AG31, AG32 and AG35 electronic modulation systems

are comprised of Maxitrol Series 14 controls. Options AG30 and AG31

systems electronically maintain a constant discharge air temperature in the

range of 55-90°F (55-75°F for C.G.A.). Option AG31 includes an overriding

thermostat. Option AG32 system will maintain a constant discharge air

temperature in the range of 80-130°F. Option AG35 maintains a discharge

temperature range of 120-160°F.

Option AG33 electronic modulation system is comprised of Maxitrol Series

44 controls. The low limit (20-60°F) and the high limit (60-140°F) for con-

trol of discharge air temperature are set at the amplifier located in the control

compartment. The space temperature is set at the remote selectrastat (55-

90°F range) located in the space. When the temperature is below the space

temperature setpoint, the control system operates the burner to automati-

cally adjust the discharge air temperature within the maximum and minimum

limits set on the amplifier.

Option AG36 is a special application gas train that is designed for controlling

the environment of a paint booth operation. The system includes a Maxitrol

A1494 amplifier, discharge air temperature sensor, dual remote discharge air

temperature selector (drying selector 80-140°F and a spray selector 60-

90°F), and two switches to control the operation of the modulating gas valve.

Electronic Modulation

Gas Control Option

AG37

Function: Control Option AG37

does not have a duct sensor or ampli-

fier. Instead, a Maxitrol A200 signal

conditioner is activated by a cus-

tomer-supplied input signal (either 4-

20 milliamps or 0-10 volt) to control

the modulation of the gas valve.

11. Gas Train Including Direct-Fired

Burner, Gas Control Systems,

Manifold Arrange-ments, and Gas

Pressure Switches

Direct-Fired Burner

Function: The design of the direct-fired burner and the con-

trolled velocity of air at the burner ensure complete combustion

through the full range of burner sizes and gas inputs as determined

by the gas control system. The velocity of air is controlled by the

profile plates and monitored by a standard low and high air pres-

sure switch.

Service: Refer to Paragraph 6 in the Maintenance Section for

instructions on burner maintenance.

WARNING: Burner profile plates are factory

set to match CFM requirements. Do not adjust

profile plates without contacting your Sales

Representative for technical assistance.

Makeup Air Gas Control Systems

• Electronic Modulation Gas Control

Options AG30, AG31, AG32, AG33, AG35,

AG36

Refer to the wiring diagrams in the main electrical box to deter-

mine which controls are on the system being serviced. NOTE: All

field-supplied control wiring for Maxitrol controls must not be

run inside conduit with line voltage wiring. To avoid any potential

electrical interference, all field-supplied wiring for Maxitrol con-

trols should be shielded wiring and must be grounded at the unit

only.

Function: These makeup air gas control systems provide heated

makeup air at a temperature controlled by a discharge air sensor.

Each system is equipped with electronic modulation controls

that modulate burner flame from 1/25th of full fire input to full

fire.

The electronic modulating-type gas controls act in response to

discharge and/or room air temperature sensors to change the gas

flow rate to the burner, thus lengthening or shortening the flame.

The BTU output is varied (modulated) to maintain the required

discharge air temperature.

These modulating gas control options are electronic because in all

cases the gas valve acts to adjust the flow of the gas to the main

burner in response to DC volts emanating from an amplifier.

When the DC voltage is between 0 and 5 volts, the main valve seat

is closed. Low fire flow is accomplished through a mechanical

bypass. The low fire flow rate is set at the factory and should not

need adjustment. However, if adjustment is necessary, refer to

the Maxitrol literature that is included in the heater owner's enve-

lope.

All of the electronic modulating gas control burner systems in-

clude low fire start. On an initial call for heat, the main burner

ignites at its lowest input. During mild weather, the burner may

then cycle off. Such full shutdown can be dictated by the outdoor

ambient cutoff control. As the outside air temperature climbs

above the setpoint of the outdoor ambient control, the burner

control circuit is de-energized. When moderately cold outside air

temperatures exist, the burner will modulate between low flame

and high flame. Low fire start and the outdoor ambient control

prevent the makeup air system from heating already warm air and

providing "too much" heat to the building.

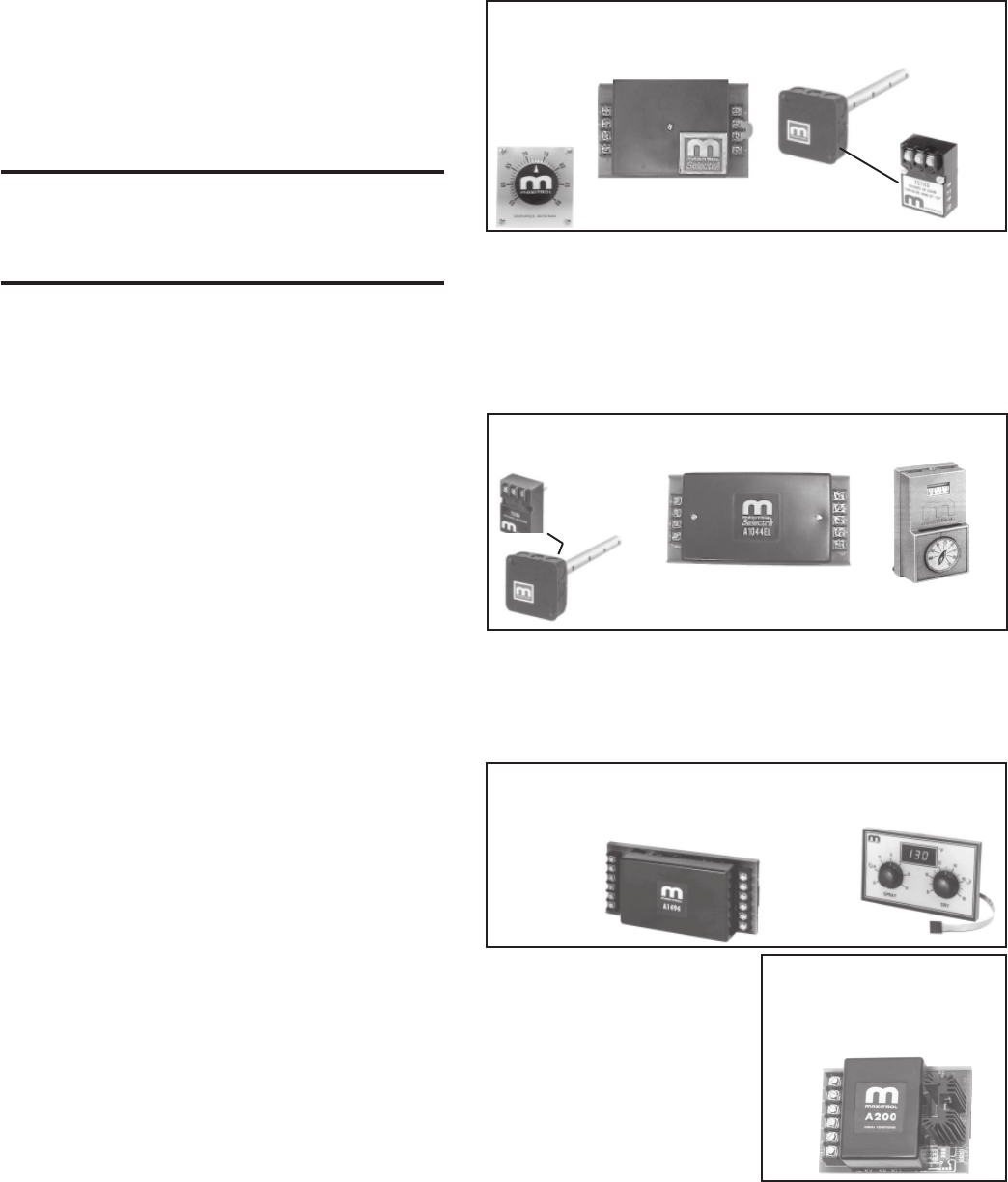

Amplifier,

P/N 133229

Selector,

P/N

133230

Figure 17 - Components of the Gas Control System used in

Option AG36 designed specifically for paint booths - controls

are mounted on a remote console

Figure 15 - Components of the Gas Control System (Maxitrol

Series 14) used in Gas Control Options AG30, AG31, AG32,

and AG35

Temperature

Sensor

Temperature

Selector

Amplifier,

P/N 148590

Mixing

Tube

Figure 16 - Components of the Gas Control System (Maxitrol

Series 44) used in Gas Control Option AG33

Amplifier,

P/N 157915

Temperature

Sensor,

P/N 119617

Temperature

Selector, P/N 86990

Mixing Tube,

P/N 90323

tioning properly. If the ignition controller locks out and there is no

other cause, the controller module must be replaced.

Figure 18 - Maxitrol A200

Signal Conditioner,

P/N 134170, used in Gas

Control Option AG37