F35425 (February 2006) Page 18 of 40

C24GA SERIES CONVECTION STEAMERS - SERVICE PROCEDURES AND ADJUSTMENTS

A. If 24VAC is present, then replace ignition

control module and retest. It may take up to

3 seconds for the module to reset if main

power is turned off then back on.

B. If 24VAC is not present, then ensure that

transformer is receiving 120VAC input. If

ignition control module transformer is

receiving proper voltage, then replace

ignition control module transformer and

retest.

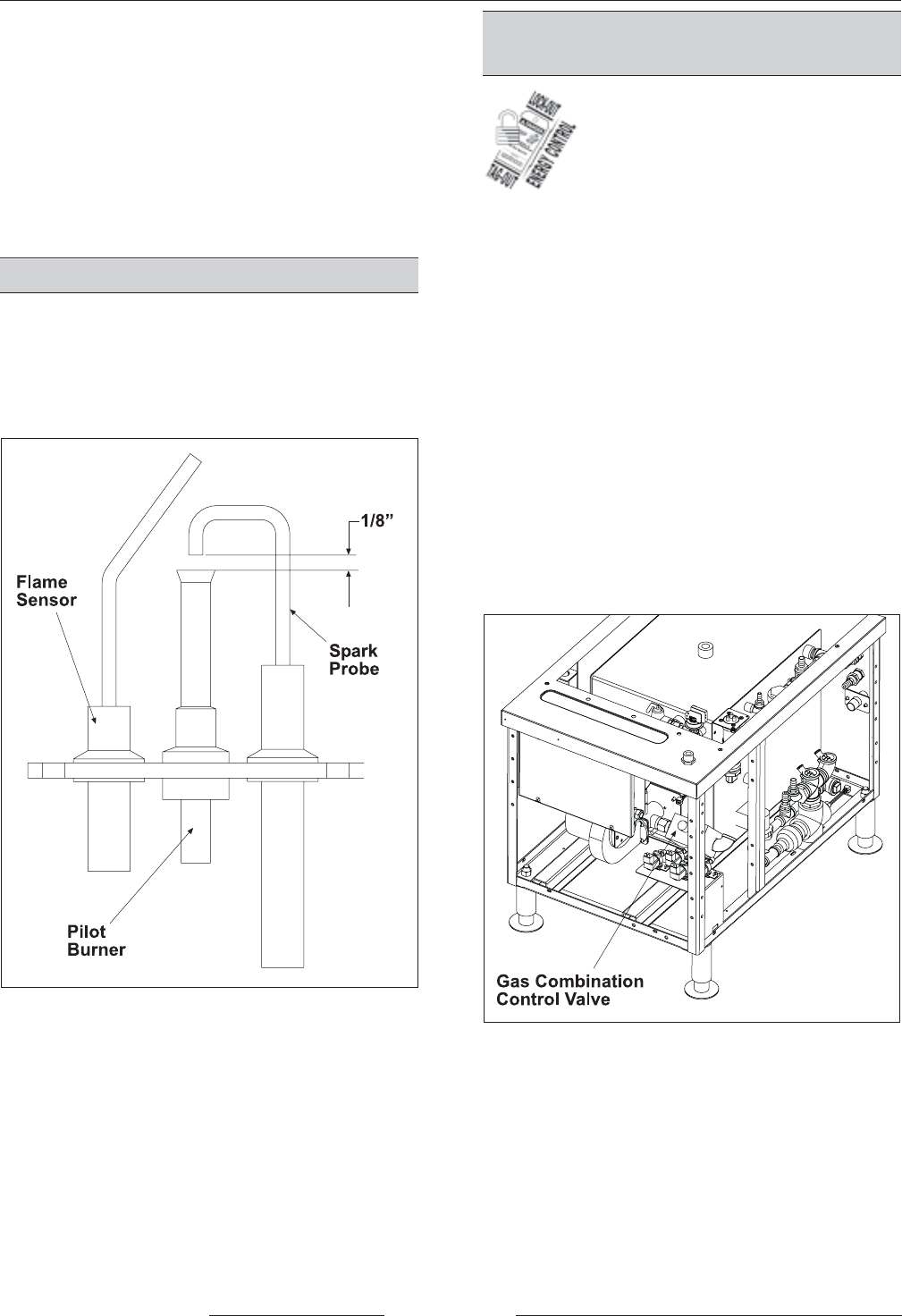

IGNITION TEST

1. The gap between the spark probe and the pilot

burner should be approximately 1/8". If the gap

appears to be excessive or poor sparking is

occurring, remove the electronic ignition pilot and

adjust gap.

2. Inspect the ceramic flame rod insulator for

cracks or evidence of exposure to extreme heat,

which can permit leakage to ground. If either of

these conditions exist, then replace the pilot

igniter assembly.

3. Check the ignition cable for tightness or

damaged insulation.

4. Check unit for proper operation.

Inspect the pilot burner orifice. This should be approxi-

mately 1/8" in diameter and free of debris.

MANIFOLD PRESSURE

ADJUSTMENT

WARNING: DISCONNECT THE

ELECTRICAL POWER TO THE

MACHINE AND FOLLOW LOCKOUT /

TAGOUT PROCEDURES.

WARNING: SHUT OFF THE GAS SUPPLY BEFORE

SERVICING THE UNIT.

WARNING: ALL GAS JOINTS DISTURBED DURING

SERVICING MUST BE CHECKED FOR LEAKS.

CHECK WITH A SOAP AND WATER SOLUTION

(BUBBLES). DO NOT USE AN OPEN FLAME.

A. CHECK ALL JOINTS PRIOR TO THE GAS

VALVE (SOLENOID) BEFORE LIGHTING

THE UNIT.

B. CHECK ALL JOINTS BEYOND GAS VALVE

(SOLENOID) AFTER UNIT IS LIT.

1. Remove front, right and left side panels from

cabinet base as outlined under COVERS AND

PANELS.

2. Turn the gas combination control valve off.

3. To measure the manifold pressure, remove the

1/8" NPT plug (pressure tap) on the outlet side of

the gas combination control valve and attach a

manometer.

4. Turn the gas supply valve and the main power

switch on. Allow generator to fill.