VHX SERIES STEAMER - SERVICE PROCEDURES AND ADJUSTMENTS

F24700 (October 2001)Page 29 of 68

D. Check ports in valve body.

9. Reverse procedure to install.

BOILER BLOWDOWN/DRAIN

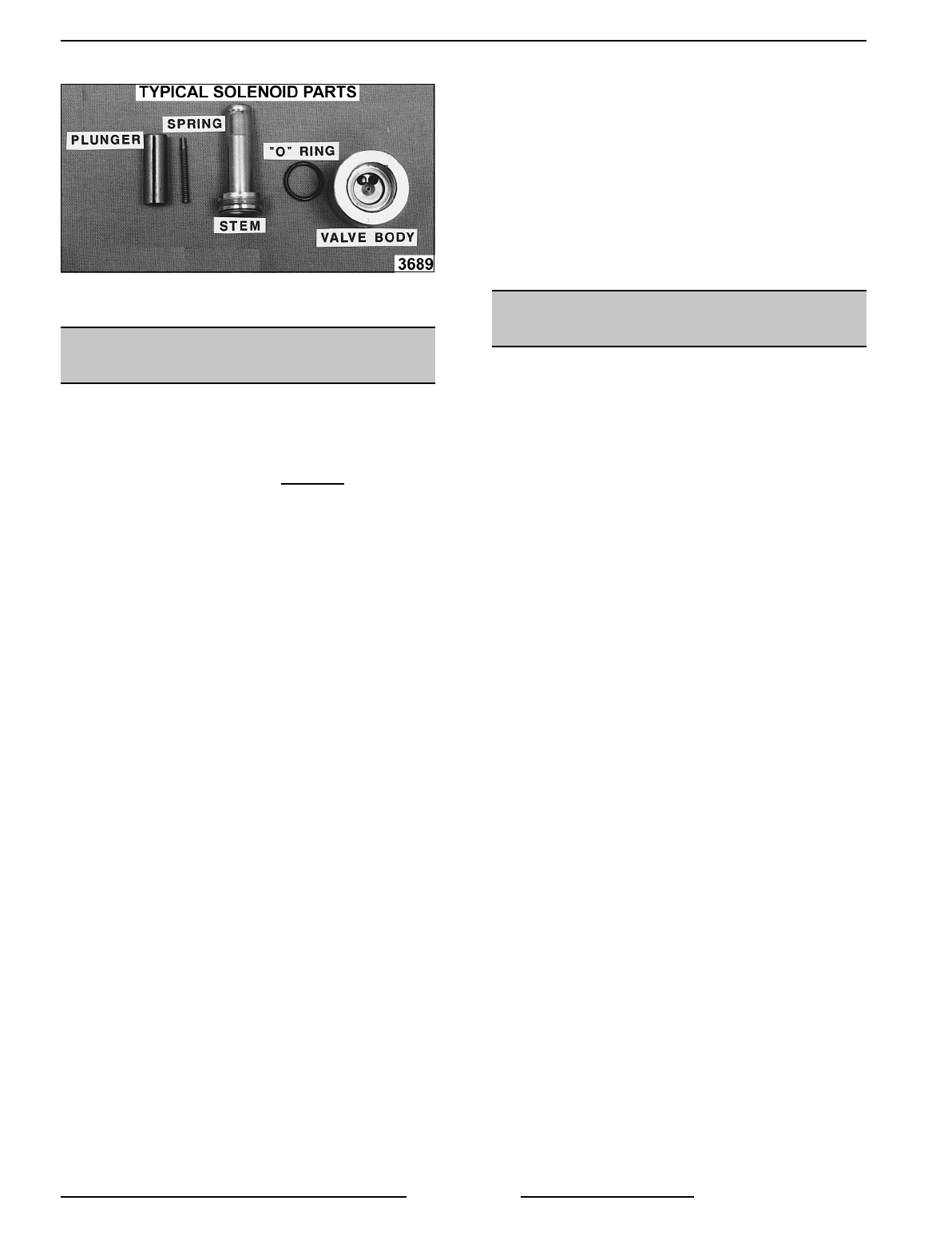

SOLENOID VALVE

The water contained in the boiler, being under

pressure, should be "blown through" this valve and

be noticeably visible exhausting out the steamer

drain. Daily boiler blowdown is essential

to proper

operation and component life by removing sediment

and scalants that may be lodged in the chamber of

the boiler.

The boiler blowdown/drain process is an automatic

function and should start whenever the power switch

is turned OFF after a normal operating cycle. The

blowdown solenoid is a normally open (N.O.) valve

that CLOSES when energized by the power switch.

When the power switch is turned OFF, the

blowdown solenoid is de-energized and the valve

OPENS to allow the boiler to blowdown.

If the blowdown operation appears to function

sluggishly or not at all, considerable scalants may

be lodged in the drain line plumbing exiting the

boiler, strainer, and/or the blowdown valve.

1. Turn the power switch OFF and allow boiler to

blowdown.

2. Turn the ON/OFF knob on the main gas valve

to OFF.

3. Remove the strainer clean-out plug located in

the center of cap.

4. Turn the power switch ON and allow the boiler

"fill water" to flush-out the drain line until no

debris is seen exiting the clean-out hole.

5. Turn the power switch and the water supply

OFF.

6. Turn the ON/OFF knob on the main gas valve

back to ON.

7. Remove and clean the strainer as outlined

under "INLINE WATER STRAINER

CLEANING".

A. If the boiler blowdown is ok, then the drain

line and valve are clear of debris and the

valve is functioning properly.

B. If considerable lime scale debris is

apparent, then not only the blowdown

valve, but also the boiler and water level

probes must be thoroughly cleaned. See

"FILL AND COLD WATER SOLENOID

VALVES" for an inspection and cleaning

procedure of a solenoid valve and

"BOILER" for a procedure on boiler

inspection, clean-out and deliming.

INLINE WATER STRAINER

CLEANING

The procedure outlined below can be used to

inspect and clean the inline water strainer for the

blowdown solenoid valve and, if installed, the inline

water strainer for the boiler fill solenoid valve. Inline

Y strainers should always be located upstream of a

water solenoid valve.

NOTE:

For proper operation, the strainer must be

installed so the water flow is directed towards the

solenoid valve and the leg of the Y with a threaded

cap is pointing downwards to catch debris.

1. Turn the power switch OFF to and allow the

boiler to blowdown.

2. When blowdown completes, shut OFF the

water supply.

3. Remove the cap and strainer screen from the

leg of the Y pointing downwards toward the

floor.

4. Remove the screen from the cap and clean any

accumulated debris from the screen and also

remove any debris trapped in the opening of

the strainer body.

NOTE:

If screen can not be thoroughly cleaned,

replace it with a new one.

5. Insert screen into cap then re-install cap to

strainer body.

6. Turn the water supply and power switch ON

and allow the boiler to reach operating

pressure.

7. Turn the power switch OFF and check strainer

for leaks, as the boiler blows down.