- 7 -

TESTING THE GAS SUPPLY SYSTEM

When gas supply pressure exceeds ½ psig (3.45 kPa), the Cheesemelter and its

individual shutoff valve must be disconnected from the gas supply piping system. When

gas supply pressure is ½ psig (3.45 kPa) or less, the Cheesemelter should be isolated

from the gas supply system by closing its individual manual shutoff valve.

FLUE CONNECTIONS

Do not obstruct flow of flue gases from the flue located on the rear of the Cheesemelter.

It is recommended that the flue gases be ventilated to the outside of the building through

a ventilation system installed by qualified personnel. Information on the construction and

installation of ventilating hoods may be obtained from the standard for "Vapor Removal

from Cooking Equipment," NFPA No. 96 (latest edition), available from The National Fire

Protection Association, Batterymarch Park, Quincy, MA 02269.

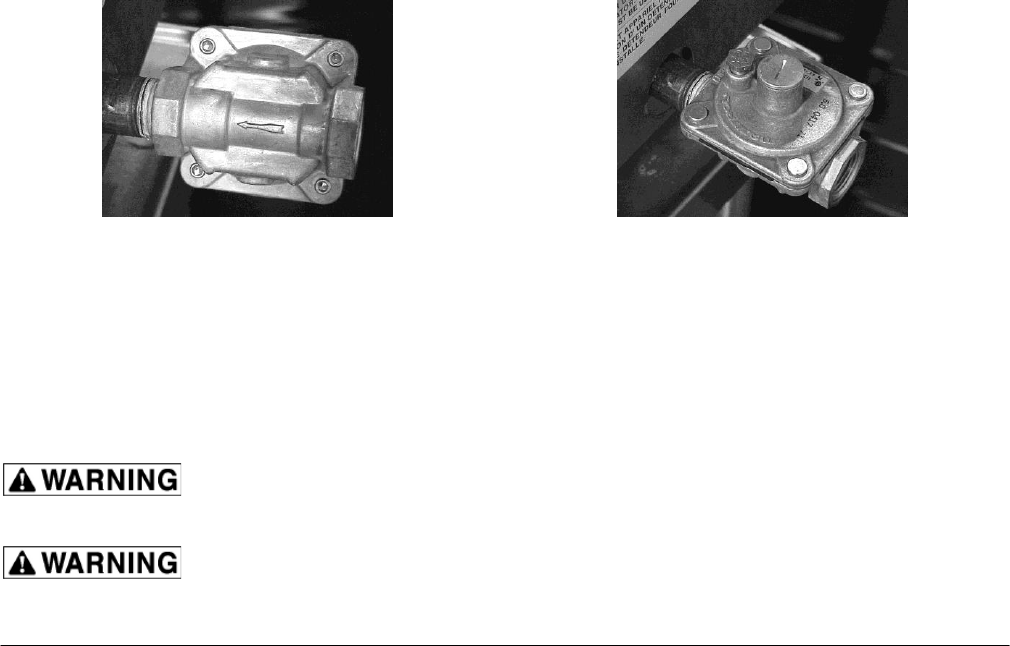

GAS PRESSURE REGULATOR INSTALLATION

Gas regulator pressure is preset at 5” Water Column (W.C.) for natural gas, and 10” W.C.

for propane gas. Minor adjustments may be required based on site specific gas pressure.

Install the regulator as close to the cheesemelter on the gas supply line as possible.

Make sure that the arrow on the underside of the regulator is oriented in the direction of

gas flow to the cheesemelter (Fig. 2) and the regulator is positioned with the vent plug

and adjustment screw upright (Fig. 3).

Fig. 2

Fig. 3

The minimum supply pressure (upstream of the regulator) should be 7-9” W.C. for natural

gas and 11-12” W.C. for propane gas. At no time should the cheesemelter be connected

to supply pressure greater than ½ psig (3.45 kPa) or 14” W.C.

Gas supply connections and any pipe joint compound must be

resistant to the action of propane gases.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.