INSTALL WATER TO OIL COOLER ON FA COMPRE-

SORS — On FA compressors, water must be piped to the oil

cooler heat exchanger (located under the suction pipe to the

compressor). The water supply may be either city water or

chilled water. Pipe city water to an open sight drain. Chilled

water enters via the cooling entering water intake (Fig. 15).

City water must be clean and noncorrosive. Water side

erosion or corrosion of the oil cooler coil may lead to

extensive machine damage not covered by the standard

warranty.

If water from the machine chilled water circuit is used for

oil cooling, it should enter the oil cooler from the entering

water line of the machine cooler. Water leaving the oil cooler

should connect to the leaving water line of the machine cooler

at a point downstream from the chilled water sensor, so that

oil cooler leaving water temperature does not affect the sen-

sor readings.

Locate the oil cooler leaving water connection at some

distance from any water temperature indicators. On single-

pass machines, water leaving the oil cooler should be con-

nected into the suction side of the chilled water pump so that

adequate pressure drop is assured for oil cooling.

The nominal conditions for oil cooler water flow are:

Flow rate .......................30gpm(1.9 L/s)

Leaving temperature ........85to100F(29to38C)

Pressure drop at oil cooler .......7.25 psid (50 kPad)

Max differential pressure across closed

solenoid valve ..............150psid (1034 kPad)

The oil cooler connections are 1

1

⁄

4

in. FPT.

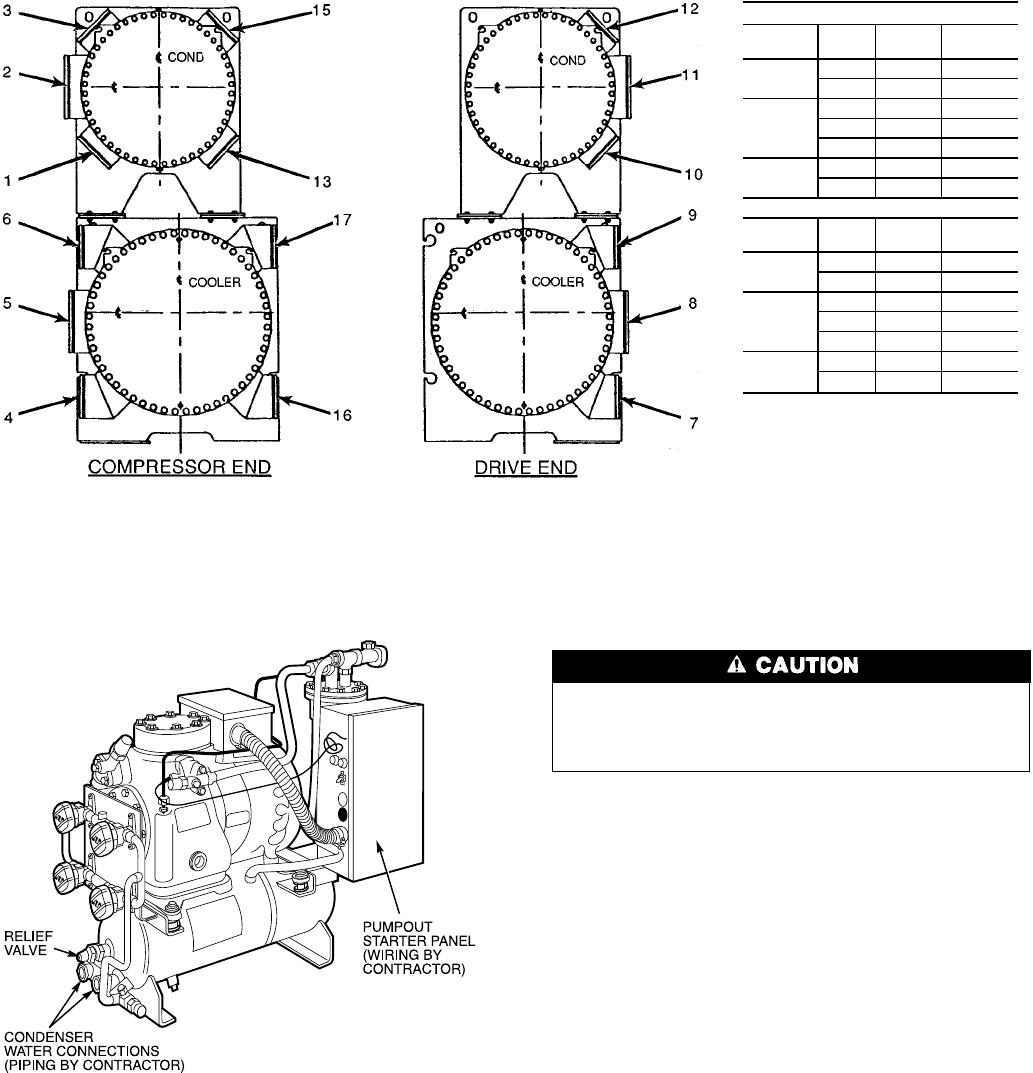

FRAME 4 MARINE WATERBOXES

COOLER WATERBOX

Pass In Out

Arr.

Code

1

85 A

58 B

2

79 C

46 D

16 17 G

3

76 E

49 F

CONDENSER WATERBOX

Pass In Out

Arr.

Code

1

11 2 P

211 Q

2

10 12 R

13 S

13 15 Y

3

10 3 T

112 U

NOTES:

1. The vents for these waterboxes are 1 in. FPT at the top of each box. The

drains are 1 in. FPT, at the bottom.

2. Victaulic connections are standard.

3. Flanged connections are optional.

Fig. 13 — Nozzle Arrangements (cont)

Fig. 14 — Pumpout Unit

19