Preparing for Installation

Plan the location for the chiller and prepare the area properly.

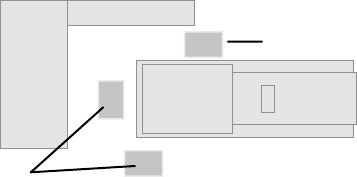

Position the chiller as close to the process machine as possible. Place the chiller in

position near the process machine so that coolant lines can be connected from the

process machine to the chiller and back.

Make sure the area where the chiller is installed has:

❒❒

A grounded power source.

Check the chiller’s serial tag for the correct amps, voltage, phase and

cycle. All wiring should be completed by a qualified technician and

comply with your region’s electrical codes.

❒❒

Clearance for safe operation and maintenance.

Ensure there is 2 ft {0.6 m} of clearance at the air intake and 2 ft

{0.6 m} of clearance at the exhaust discharge for proper operation. Air

flow is generated by the motor driven fan. Air flow is from the outside

of the chiller, through the condenser and exhausted through the unit.

Exhaust air can not be ducted on motor driven fan models.

Position the locking casters to prevent the chiller from moving. For

maintenance and servicing, be sure there is enough clearance to

remove all access panels completely.

❒❒

Available water source.

Ensure water make-up source is plumbed to the chiller’s installation

location. High points in the plumbing require vent valves; low points

require drain valves.

3-4 l Installation

NOTE: Models must be posi-

tioned so that the condenser

air inlet is no warmer than

95°F {35°C} and the condenser

air outlet is not blocked or

restricted in any way.

✐

Chiller

Process machine

Alternate

locations

NOTE: Locate models away

from heat producing equip-

ment. These items will affect

ambient air conditions and the

performance of the chiller.

✐