1-24

A modular basket lift consists of a toothed rod to which the basket lift arm is attached, a reversible-

drive gear motor, and a pair of roller activated microswitches. The gear motor engages the teeth in

the rod, moving it up or down depending upon the direction of rotation of the motor. Microswitches

at the upper and lower limits of movement stop the motor when the basket is in the full up or full

down position and also reverse the direction of current flow thus reversing the motor direction.

When the manually set or programmed cooking time has elapsed, current is again supplied to the

basket lift and the basket is raised.

When the timer times-out, power is supplied to the opposite pole of the motor through the upper

microswitch. The motor drives the rod upward until it loses contact with the upper microswitch,

cutting power to the motor and stopping the lift.

In units configured for Basket Lift Timer Controllers or Computer Magic computers, the process is

almost identical. The difference is that the push button mechanical timer is replaced with timing cir-

cuitry in the computer or controller. The specific cook times (and other settings) are programmed

into the computer or controller by the operator. When the product button is pressed, the timing cir-

cuitry activates a coil in the basket lift relay to supply power to the lower microswitch. As with the

manually controlled units, the microswitches stop the motor at the lift’s upper and lower travel limits

and reverse the direction of current flow thus reversing the motor direction.

Problems with the basket lift system can be grouped into three categories:

• Binding/jamming problems

• Motor and gear problems

• Electronics problems

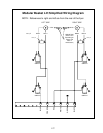

M

2-Pole

Mech

Timer

HN

N.O.

Upper Limit

Microswitch

N.C.

Lower Limit

Microswitch

4 or 6

3

When the timer button is pushed, the lower circuit is activated,

causing the basket lift to be lowered, closing the normally open

upper microswitch. When the lower normally closed microswitch

is opened by the downward moving basket lift rod, power to the

motor is cut. When the timer times-out, the upper circuit is

activated, causing the basket lift to be raised, reclosing the lower

microswitch. When the basket lift rod clears the upper

micorswitch, allowing it to reopen, power to the circuit is cut and

the motor stops. Pushing the timer button again restarts the

cycle.

1 or 5

Manual (Push-Button)

Modular Basket Lift Simplified Schematic

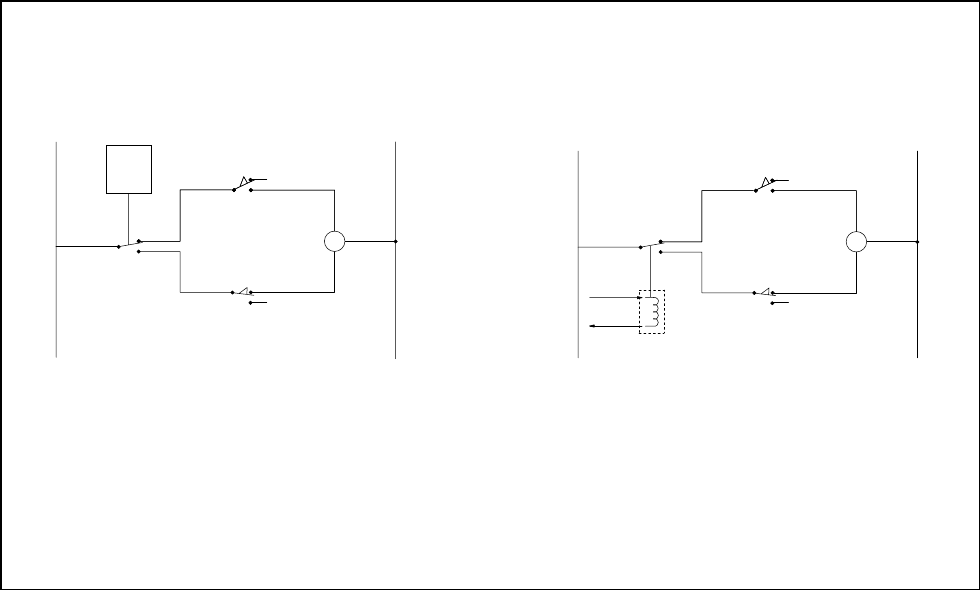

M

HN

N.O.

Upper Limit

Microswitch

N.C.

Lower Limit

Microswitch

6

When the product button is pushed on the computer/controller,

current flows through a coil in the basket lift relay, causing the

lower circuit to be activated. This causes the basket lift to be

lowered, closing the normally open upper microswitch. When the

lower normally closed microswitch is opened by the downward

moving basket lift rod, power to the motor is cut. When the

computer/controller times-out, the current to the relay coil is cut,

allowing the upper circuit to be activated. This causes the basket

lift to be raised, reclosing the lower microswitch. When the basket

lift rod clears the upper micorswitch, allowing it to reopen, power

to the circuit is cut and the motor stops. Pushing the product

button again restarts the cycle.

Computer/Controller

Modular Basket Lift Simplified Schematic

To computer/controller

via interface board

Basket Lift

Relay

3

1 or 4

5