6-11

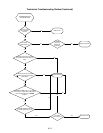

6.4 Troubleshooting

6.4.1 How the Autofill System Works

The heart of the automatic filling (AutoFill) system is a normally closed solenoid valve that opens

when 24VAC is applied. When the controller is turned on, it checks to see if the upper water level

sensor is grounded by contact with water in the cookpot. If it is not, circuitry in the controller forms

a ground for the 24VAC supplied to the solenoid, allowing the valve to open. When the water level

in the cookpot reaches the upper water level sensor, the sensor is grounded, causing the controller to

break the solenoid ground, thus shutting off the inflow of water.

Starch or lime build-up on the upper water level sensor may keep the ground from forming, therefore

the sensor must be kept clean and its lead firmly connected. NOTE: Do not use deliming solution to

clean these units. Use of deliming solution will damage all stainless steel parts.

This unit will not operate with distilled water. Pure water is non-conductive, so the required ground

cannot be formed. If highly filtered or purified water is used, adding ⅛-cup of baking soda to the

water will usually provide sufficient mineral content for the ground to form.

NOTE: In units equipped with the AutoSkim feature, when the skim switch on the controller is

pressed, a logic circuit in the controller automatically interrupts the 24VAC ground for three seconds

every minute until the switch is again pressed. Therefore, failure of the AutoSkim feature will be

due to a malfunctioning controller and not the solenoid valve.

6.4.2 How the Water Heating System Works

To prevent energizing the heating elements when there is no water in the cookpot, these units are

equipped with a low-water level sensor that must be grounded by contact with the water in the

cookpot before the control circuitry will apply power to the elements.

Starch or lime build-up on the low-water level sensor may keep the ground from forming, therefore

always make sure the sensor is clean and its lead is firmly connected. NOTE: Do not use deliming

solution to clean these units. Use of deliming solution will damage all stainless steel parts.

The units will not operate with distilled water since pure water is non-conductive. In order for the

ground to form, there must be some mineral content in the water. If highly filtered or purified water

is used, add ⅛-cup of baking soda to the water each time the cookpot is emptied and refilled.

In addition to the low-water level sensor discussed above, the water heating system has five more parts:

the high-limit thermostat, the temperature probe, the contactor block, the element, and the controller.

The high-limit thermostat functions as a normally closed switch. If the water in the cookpot falls

below the low-water level sensor but the sensor remains grounded for whatever reason, the high-

limit switch will open when the element temperature reaches 400ºF ±15 (204ºC ± 9), cutting off

power to the contactor coil and thus to the element.

The temperature probe is used only when the unit is in the simmer mode. When the operator

selects the simmer mode, logic circuits in the controller monitor the temperature of the water and

cycle power to the element on and off to maintain the temperature at the setpoint programmed into

the controller.