--- 20 ---

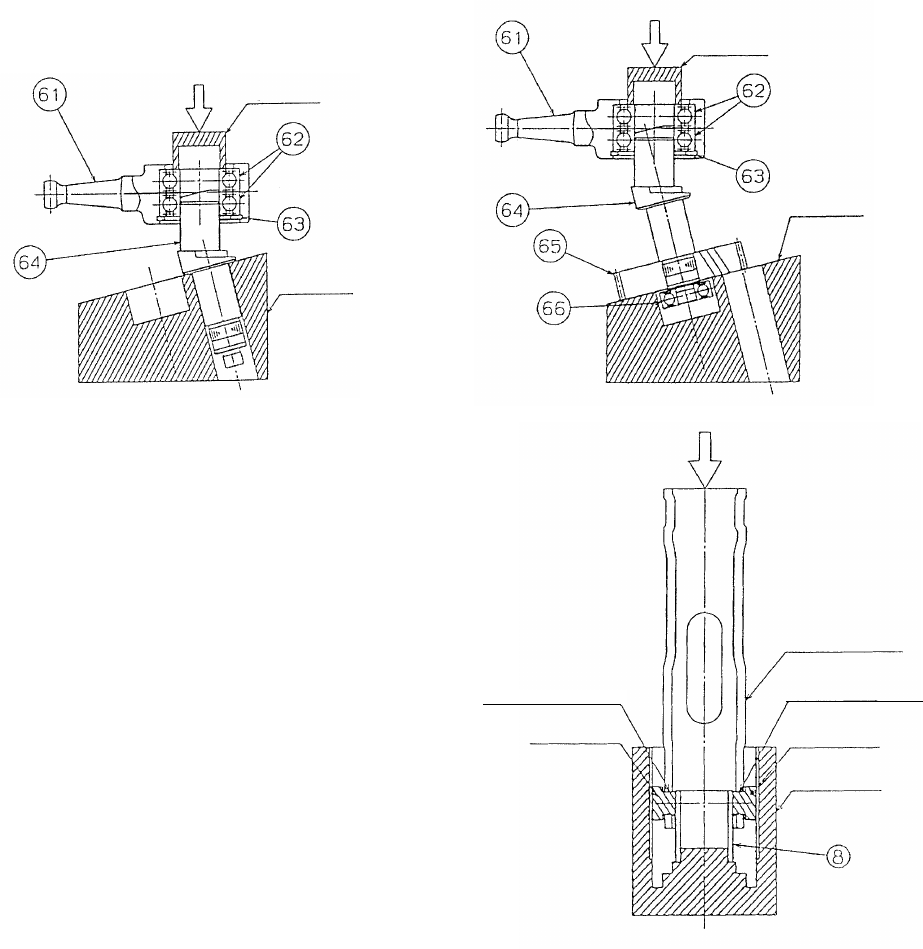

Fig. 13-a

2. Reassembly

Reassembly can be accomplished by following the disassembly procedures in reverse. However, special

attention should be given to following items.

(1) Press-fitting the Recipro Plate [61] ass'y into Second Shaft (A) [64] (Fig.13)

Tool required: Special repair tool J-315

Mount the two Ball Bearings 6003VVCMPS2L [62] and the Retaining Ring for D35 Hole [63] to the Recipro

Plate [61] to complete the assembly (recipro plate ass'y).

(a) If the Gear [65] and the Ball Bearing 608VVC2PS2L [66] are not mounted to Second Shaft (A) [64],

mount Second Shaft (A) [64] and the recipro plate ass'y to the special repair tool J-315 and press-fit it in

the direction of the arrow with a hand press as shown in Fig. 13-a.

(b) When the Gear [65] and the Ball Bearing 608VVC2PS2L [66] are mounted to Second Shaft (A) [64],

mount Second Shaft (A) [64] and the recipro plate ass'y to the special repair tool J-315 and press-fit it in

the direction of the arrow with a hand press as shown in Fig. 13-b.

Be careful of the direction when press-fitting the recipro plate ass'y.

(2) Press-fitting Metal (A) [8] into the guide sleeve (Fig. 14)

(Metal (A) [8] and the guide sleeve are supplied together as

the Guide Sleeve Ass'y [9].)

Tool required: Special repair tool J-316 (adjusted to the

proper dimensions)

Insert Metal (A) [8] into the press-fitting portion of the guide

sleeve so that the outer flat section of the metal can be seen

from the 8 mm dia. hole of the guide sleeve. (An inspection

hole is provided on one side of the metal.) Mount the two

special repair tools J-316 in the 8 mm dia. hole as shown in

Fig. 14. Push the guide sleeve in the direction shown by the

arrow as far as it will go with a hand press.

Fig. 14

Fig. 13-b

J-315

J-315

J-315

J-315

J-316

Guide sleeve

J-316

J-316

8 mm dia. hole

8 mm dia. hole