--- 7 ---

5-2. Optional Accessories

The cutting speed of the Model CR 13VA is substantially higher than that of the current model, however, the

conventional HCS blades may be broken in heavy applications such as house demolition, etc. To cope with this

problem, the BI-METAL blades shown in Table 2 are provided. The BI-METAL blades are tough and rarely break

since they are made by electron-beam welding together of two different types of steels. A very hard steel called

"DM05" (JIS: SKH51 or equivalent molybdenum containing high speed tool steel) or "Matrix II" (JIS: SKH59 or

equivalent cobalt containing high speed tool steel) is used at the cutting edges, and a flexible steel for spring

material is used for the blade main body. So these BI-METAL blades are remarkably stronger than the HCS

blades.

(1) HCS blades

The blade numbers of HCS blades in Table 1 are engraved in the vicinity of the mounting position of each blade.

Select appropriate blades by referring to Tables 1 and 3 below.

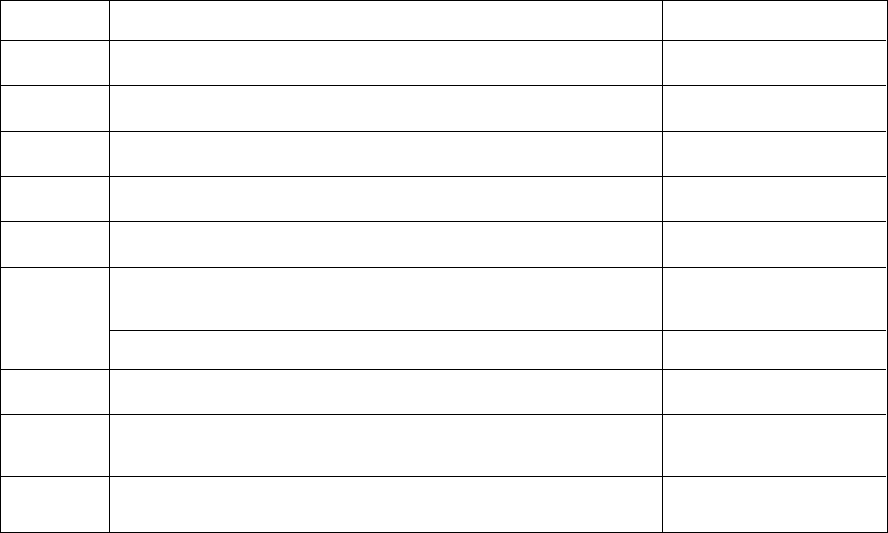

Table 1: HCS blades

For cutting and roughing lumber

Blade No. Uses Thickness (mm)

For cutting steel pipes less than 105 mm in outer diameter 2.5 --- 6

No. 1

No. 3

No. 96

No. 95

No. 9

No. 8

No. 5

No. 4

No. 2

For cutting steel pipes less than 30 mm in outer diameter

For cutting steel pipes less than 30 mm in outer diameter

For cutting and roughing lumber

For cutting vinyl chloride pipes less than 105 mm in outer

diameter

For cutting and roughing lumber

For cutting steel pipes less than 130 mm in outer diameter

For cutting steel and stainless pipes less than 105 mm in

outer diameter

For cutting steel and stainless pipes less than 30 mm in

outer diameter

2.5 --- 6

50 --- 70

2.5 --- 6

Below 2.5

Below 2.5

Below 3.5

Below 30

Below 105

2.5 --- 15