4

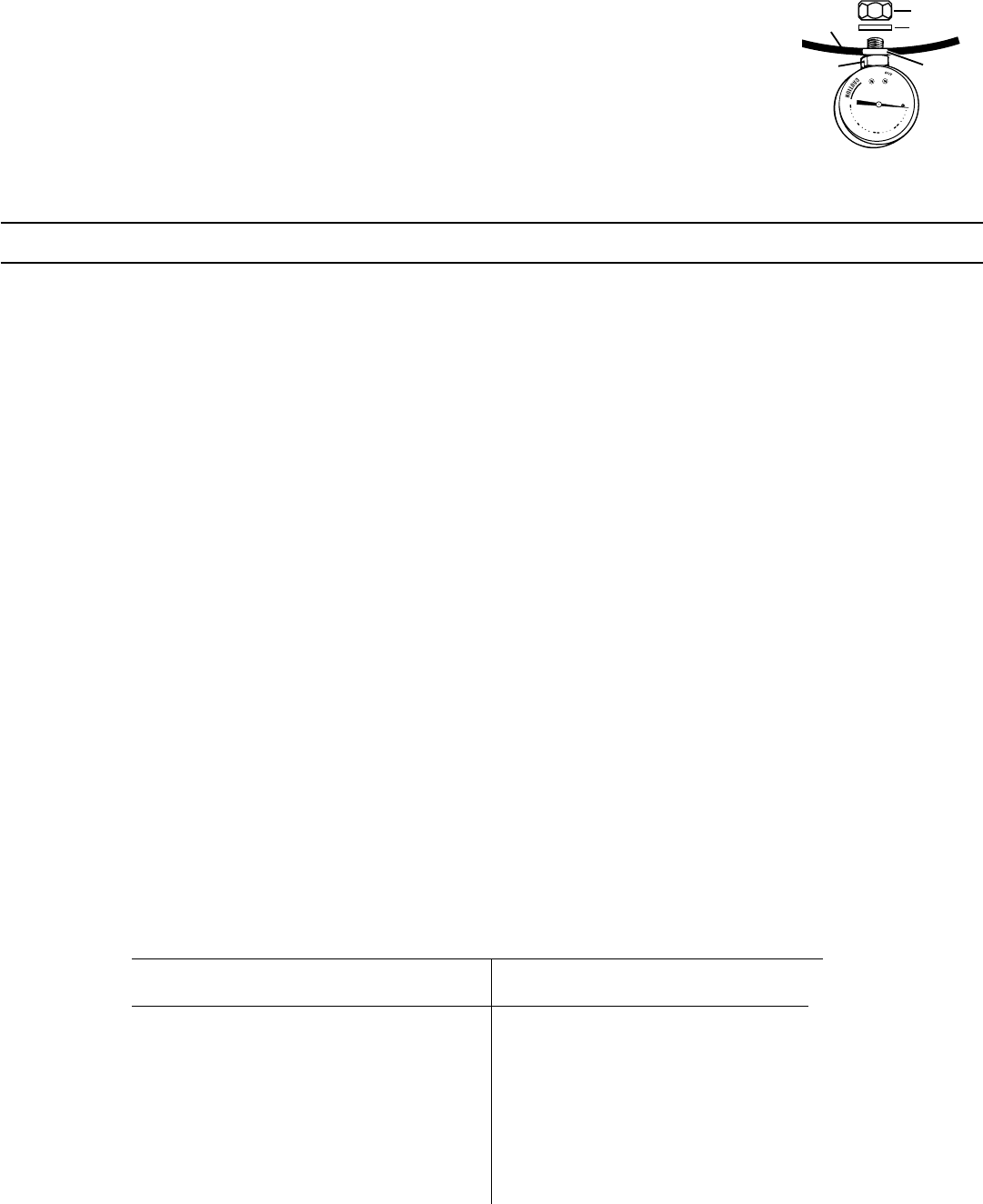

5.Attachthedialgaugetothecannercoverbyrstremovingthenut,metalwasher,andwhitecompression

gasket from the threaded end of the dial gauge. Then, turn the cover upside down and starting from the

bottom, insert the threaded end of the dial gauge up through the hole in the center of the cover until the

metal base rests on the cover. While holding the dial gauge in place, position the gasket (the gasket should

restwithinthecoverhole),metalwasher,andthenthenutonthethreadedendofthegauge(Fig.C)and

tightenwithngers.Ifnecessary,lightlytightenwithawrench.

HELPFUL HINT: To help yourself understand the operation of the pressure canner, pour 4 cups of water

into the canner and follow the step-by-step instructions beginning with step 5 on page 5. For actual usage of

the canner, follow the complete instructions beginning on page 5 for pressure canning and on page 18 for pressure cooking.

PRESSURE CANNING

The United States Department of Agriculture recommends the pressure canner as being the only safe method for canning low acid

foods — vegetables, meats, and poultry.

There are invisible microorganisms present all around us. Fruits, vegetables, and meat contain these microorganisms naturally, and yet,

theyarenotaproblemunlessfoodislefttositforextendedperiodsoftime,causingfoodspoilage.Thisisnature’swayoftellingus

whenfoodisnolongerttoeat.

There are four basic agents of food spoilage — enzymes, mold, yeast, and bacteria. Canning interrupts the natural spoilage cycle so food

can be preserved safely. Molds, yeast, and enzymes are destroyed at temperatures below 212°F, the temperature at which water boils

(exceptinmountainousregions).Therefore,boilingwaterprocessingissufcienttodestroythoseagents.

Bacteria, however, are not as easily destroyed. The bacteria clostridium botulinumproducesasporethatmakesapoisonoustoxinwhich

causes botulism. This spore is not destroyed at 212°F. In addition, the bacteria thrive on low acid foods in the absence of air. For a safe

food product, low acid foods need to be processed at 240°F, which can be achieved only with a pressure canner.

In pressure canning, some of the water in the pressure canner is converted to steam, which creates pressure within the canner. As pressure

increases, temperature increases, 5 pounds pressure — 228°F, 10 pounds pressure — 240°F, 15 pounds pressure — 250°F. This pressur-

ized heat destroys the potentially harmful bacterial spores. As the jars cool, a vacuum is formed, sealing the food within and preventing

any new microorganisms from entering and spoiling the food.

As a safeguard against using canned foods which may be affected with spoilage that is not readily detected, boil all low acid foods and

tomatoesfor10minutesataltitudesbelow1,000feet.Extendtheboilingtimeby1minuteforeach1,000footincreaseinaltitude.

Many times odors that cannot be detected in the cold product will become evident by this method. If, after boiling, food does not smell

or look right, discard it without tasting.

MASON JARS: While there are many styles and shapes of glass jars on the market, only Mason jars are recommended for home canning.

Masonjarsareavailablein½pint,pint,andquartcapacitieswiththreadsonwhichacapmaybescrewed.Seethechartbelowforthe

jar capacity of your canner. Additional information may be obtained from the manufacturers of Mason jars.

CLOSURES FOR MASON JARS:Thetwo-piecevacuumcapconsistsofaatmetallidheldinplacewithascrewband.Arubber

compoundontheundersideofthelidformsasealduringprocessing.Followtheclosuremanufacturer’sdirectionsforusingthetwo-

piece cap and for testing for a proper seal. If the closure has not sealed, completely reprocess or use the food immediately. Refer to the

closuremanufacturer’sdirectionsforadditionalinformation.

MAXIMUM JAR CAPACITIES

(For Model Numbers beginning with 0175) (For Model Numbers beginning with 0178)

Regular jars Wide mouth jars Regular jars Wide mouth jars

12 half-pints 8 half-pints 24 half-pints 16 half-pints

10 pints 8 pints 20 pints 16 pints

7 quarts* 7 quarts* 7quarts 7 quarts

*Donotusetheboilingwatermethodwith

quartjars.

Toachievethemaximumjarcapacitywhen

pressure canning, it will be necessary to

doubledeckpintand½pintjars,seepage7.

For boiling water method, do not double

deck jars.

READ INSTRUCTIONS

BEFORE OPERATING

psi

0

5

10

15

20

Fig. C

Metal

Base

Nut

Metal Washer

White

Compression

Gasket

Cover