6

necessary to bring pressure to the correct setting and begin processing countdown from the beginning

for the full amount of time.

HelpfulHint:Tomoreeasilymaintainpressure,itmaybebenecialtoreducetheheatwhenthedial

gaugeregisters1½to2poundslessthanthedesiredpressure.However,donotbegintheprocessing

countdown until correct pressure is reached.

10. At the end of processing time, turn burner to “off” and remove canner from heat source. NOTE:

Lift pressure canner to remove it from burner. Sliding cookware can leave scratches on stovetops.

11. Let pressure drop of its own accord. Do not attempt to speed the cooling of the canner, which can

causejarbreakage,liquidlossfromthejarsandotherproblems.Pressureiscompletelyreduced

when the air vent/cover lock and overpressure plug have dropped and no steam escapes when the

pressure regulator is lifted. Do not use the dial gauge as an indicator for when pressure is completely

reduced.

12. When pressure has been completely reduced, remove pressure regulator from vent pipe and let

canner cool for 10 minutes. Do not remove the pressure regulator until pressure is completely

reduced and the air vent/cover lock has dropped. Always remove pressure regulator before opening

the cover.

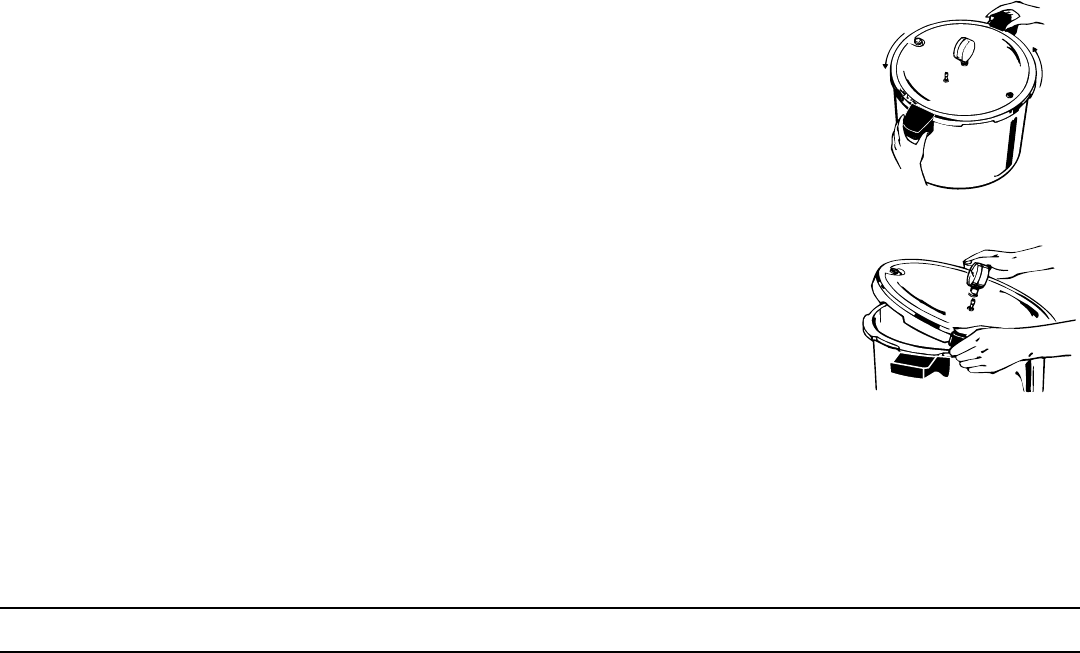

13. Toremovecover,turncounter-clockwiseuntilcoverhitsstop(Fig.K).Coverhandleswillbebeyondthebodyhandles.Ifcover

seems to stick or is hard to turn, do not force it open. Sticking may indicate that there is still pressure inside the canner. If in doubt

about pressure being completely reduced, let the canner stand until cool before removing the cover.

14.Liftcannercovertowardyoutokeepsteamawayfromyouwhenopening(Fig.L).

15. Remove jars from canner. Set jars upright on board or cloth, away from draft to cool. When jars are cold, test seal, remove bands,

wipe jars, label, date, and store in a cool, dry place.

HELPFUL HINTS FOR PRESSURE CANNING

❖ Bubbles often appear in the jar after it is removed from canner because food is still boiling in jar. Ordinarily bubbles do not appear

once the product has been allowed to thoroughly cool.

❖Jarbreakageduringprocessingiscausedby:(1)Packingjartoosolidlyoroverlling;(2)Weakened,crackedjars;(3)Jarstouching

bottomofcanner;(4)Lidsimproperlytightened;(5)UseofjarsotherthanMasonjars.

❖ Liquidlostfromjarsduringprocessingiscausedby:(1)Packingjartoosolidlyoroverlling;(2)Insufcientexhaustperiod;(3)

Variation or sudden lowering of temperature in the canner. When processing food, pressure regulator should not be taken off the vent

pipeandcovershouldnotberemoveduntilairvent/coverlockhasdroppedandpressurehasbeencompletelyreduced;(4)Failure

toadjustjarlidsaccordingtomanufacturer’sdirections.

❖ Thelossofliquidfromjarsduringprocessingmaybeunattractivebutitwillnotaffectthesafetyofthefoodaslongasthejarwas

processed correctly and is sealed.

❖ It is better to overprocess food than underprocess. Underprocessing may result in spoilage and unsafe food.

❖ Foodspoilageorjarsnotsealingiscausedby:(1)Failuretofollowexacttimetablesandrecipes;(2)Failuretowipesealingedgeof

jarcleanbeforeplacinglidonjar;(3)Foods,seeds,orgreaselodgedbetweenlidandjar;(4)Jarswhicharenickedorcrackedorhave

sharpsealingedges;(5)Failuretoadjustjarlidsaccordingtomanufacturer’sdirections;(6)Turningjarsupsidedownwhilejarsare

cooling and sealing.

❖ Flat sour, a type of food spoilage, is caused by canning overripe food or allowing precooked foods to stand in jar too long before

processing. It may be prevented by using fresh products and properly processing, cooling, and storing. Flat sour shows no indication

of spoilage until jar is opened.

❖ Mold can form only in the presence of air. Therefore, jars are not sealed if mold is present.

❖ Theblackdepositsometimesfoundontheundersideofalidiscausedbytanninsinthefoodorhydrogensuldewhichisliberated

from the food by the heat of processing. This does not indicate spoilage.

❖ If a jar does not seal, use the food at once, freeze or repack using different lids. Reprocess for the full recommended processing time.

❖ Two-piece vacuum caps seal by the cooling of the contents of the jar, not through pressure of the screw band on the lid. Therefore,

althoughthescrewbandisrmlytight,thejarisnotsealeduntilcooled.Duringprocessing,theexiblemetallidpermitsairtobe

exhaustedfromthejar.

❖ Adjusttwo-piecevacuumcapsbyscrewingbandsdownevenlyandrmlyuntilapointofresistanceismet–ngertiptight.Donot

useundueexertion.

Fig. L

Fig. K