26

Fit the Handles

Remove the 4mm Allen screws from the doors with

the hexagon key tool. Use the screws to fi t the door

handles.

The handles should be above the fi xings.

Remove the 4mm Allen screws from the top corners of

the fascia and fi x the front handrail in position.

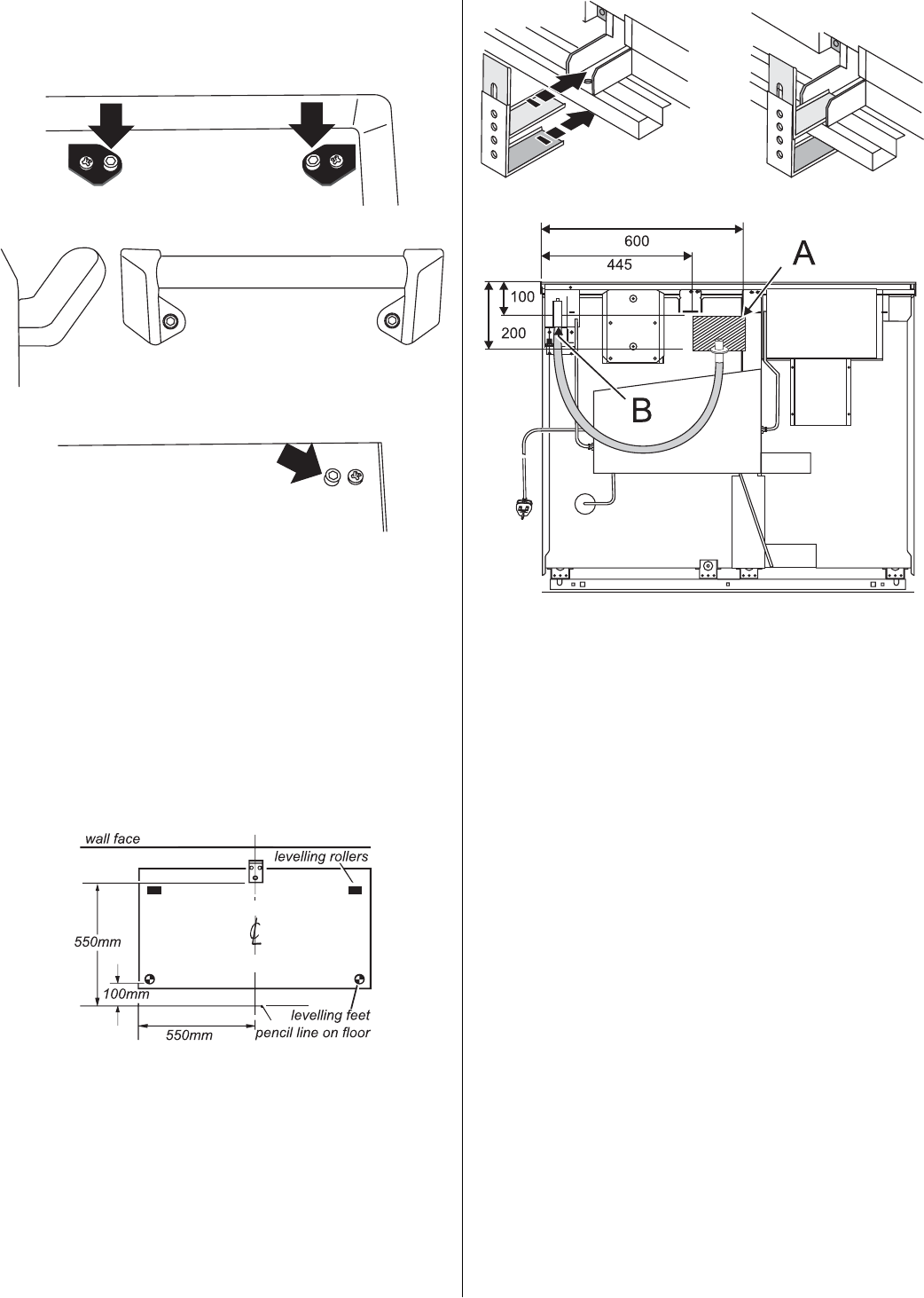

Fitting a stability bracket

A stability bracket or chain (not supplied by with the

cooker) should be fi tted when the cooker is connected

to a fl exible gas supply.

When fi tting a stability bracket read these instructions

together with the leafl et supplied with the bracket.

1. Place the cooker in its intended position and level the

cooker.

2. Draw a pencil line 100mm from the front edge of the

levelling feet.

3. Mark the centre line for the bracket by measuring

550mm from the left hand side of the cooker.

4. Lower the front roller and move the cooker forward.

5. Measure back from the pencil line 550mm to locate

the front edge of the bracket. Fix the bracket to the

fl oor.

6. Measure the height from fl oor level to engagement

edge in back of cooker. Add 3mm to this dimension

and assemble the stability bracket to this height. (i.e.

from fl oor level to underside of the top member) and

ensure the bracket does not foul the oven burner

assembly.

Gas Connection

view from the rear

A position for gas supply connector

B appliance gas inlet

The Gas supply needs to terminate with a down facing

bayonet. The rear cover boxes limit the position of the

supply point.

Because the height of the cooker can be adjusted and

each connection is different it is diffi cult to give precise

dimensions. Ideally the house supply bayonet should

be in the shaded area shown in the diagram. Although

a 3ft hose can be used, a 3ft6” or 4ft hose will allow

slightly more fl exibility in the positioning of the bayonet

and make moving the cooker easier. The hose should

be fi tted so that both inlet and outlet connections are

vertical so that the hose hangs downwards.

The connector is located just below the hotplate level

at the rear of the cooker.

For Natural Gas the fl exible hose must be in

accordance with B.S.669.

For LP Gas it should be capable of 50mbar

pressure, 70°C temperature rise and carry a red

stripe, band or label.

If in doubt contact, your supplier.

Screw connect the threaded end of the hose into the

gas inlet in the underside of the connector block on the

back of the cooker.

After completing the gas connection, check the cooker

is gas sound with a pressure test. When checking

for gas leaks do not use washing up liquid - this can

corrode. Use a product specifi cally manufactured for

leak detection.