21

Model 220 Operating Procedures

Disassembly

MAKE SURE THE CONTROL SWITCH IS

IN THE “OFF” POSITION. Failure to follow this

instruction may result in severe personal injury from

hazardous moving par ts.

Step 1

Remove the cross bar screw assembly, the hinges,

pins, the cross bar , the freezer door, the beater

assembly, the scraper blades, and the drive shaft from

the freezing cylinder. Alsoremove theadjustable shelf.

Take these parts to the sink for further disassembly

and cleaning.

Step 2

Remove the rear dr ip tray from the side panel.

Note: If the d riptray is filled withan excessive amount

of mix, it is anindication that the drive shaft sealshould

be replaced or was improperly lubricated.

Brush Cleaning

Step 1

Prepare a sink with a n approved cleaning solution (ex-

ample: Kay- 5R or S tera- SheenR). USE WARM

W ATER AND FOLLOW THE MANUFACTURER’S

SPECIFICATIONS.

If an approved c leaner other than (example: Kay- 5R

or Stera- SheenR) is used, dilute it according to the

label instructions. IMPORTANT: Follow the label

directions. Too STRONG of a solution can cause parts

damage, while too MILD o f a solution will not provide

adequate cleaning. Make s ure all brushes provided

with the freezer are available for brush cleaning.

Step 2

Remove the seal from the drive shaft.

Step 3

From the freezer door:

Remove the keeper pin on the valve body. Turn the

draw rod handle and pull the draw rod a ssembly out of

the valve body. Unscrew the valve piston and slide the

bearing holder down of f the draw rod. Remove the

o- ring from the valve piston and the bearing holder.

Remove thelargeo- ring andthe front bearing from the

back of the freezer door.

Remove the keeper pin from the cover cap assembly

and remove the cover cap assembly.

Note: To remove o- rings, use a single service towel

to grasp the o- ring. Apply pressure in an upward

direction until the o- ring pops out of its groove. With

the other hand, push the top of the o- ring forward. It

will roll out of the groove and can be eas ily removed.

If there is more than one o- ring to be removed, always

remove the rear o- ring first. This will allow the o- ring

to slide over the forward rings without falling into the

open grooves.

Take these parts to the sink for c leaning,

Step 4

Thoroughly brush clean all disassembled par ts in the

cleaning solution, makingsureall lubricantand mixfilm

is removed. Place all the cleaned parts on a clean dry

surface to air dry overnight.

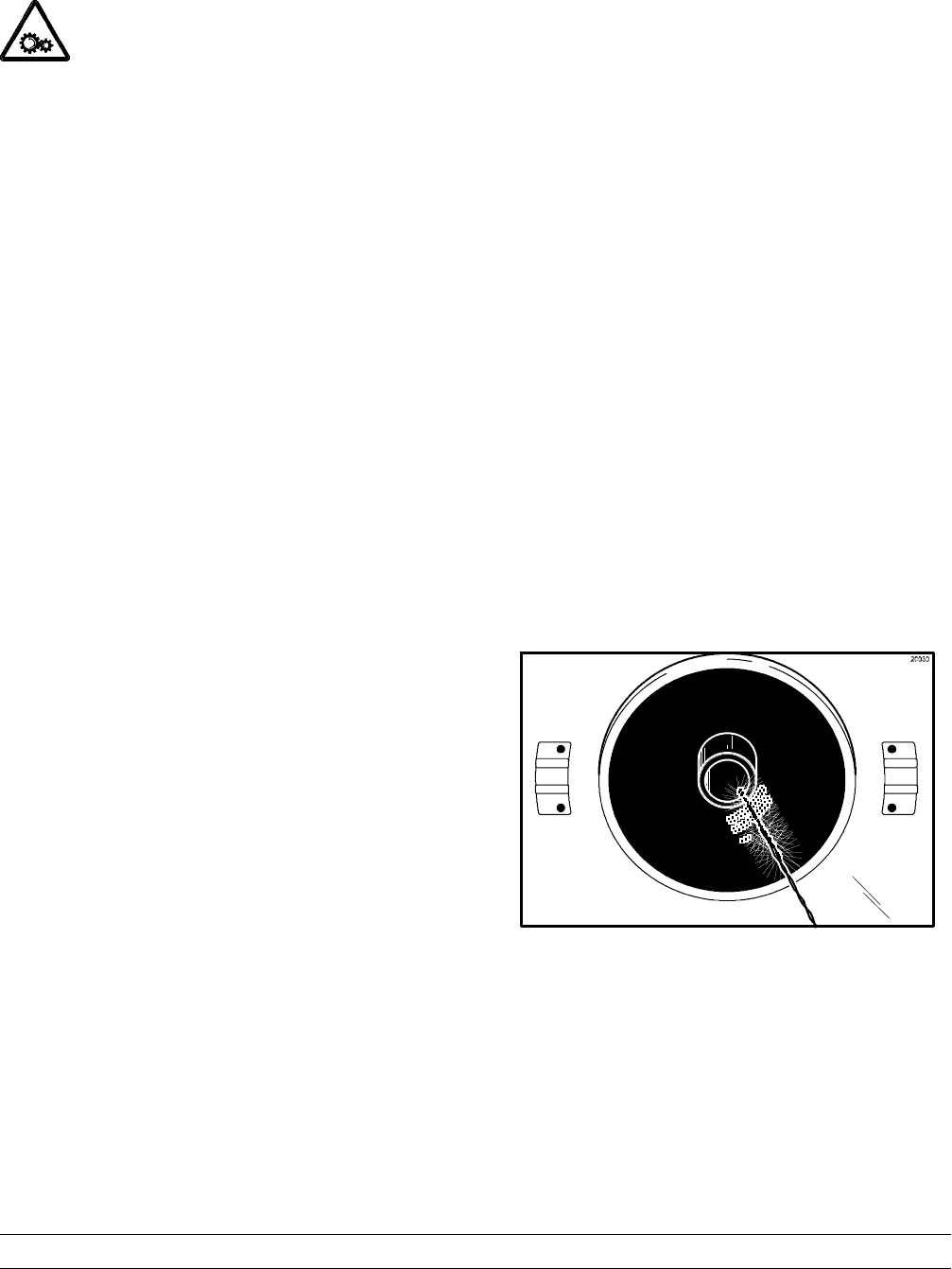

Step 5

Return to the freezer with a small amount of cleaning

solution. With the black bristle brush, brush clean the

rear shell bearing at the back o f the freezing cylinder.

Figure 41

Step 6

Wipe clean the shelf and all exterior surfaces of the

freezer.