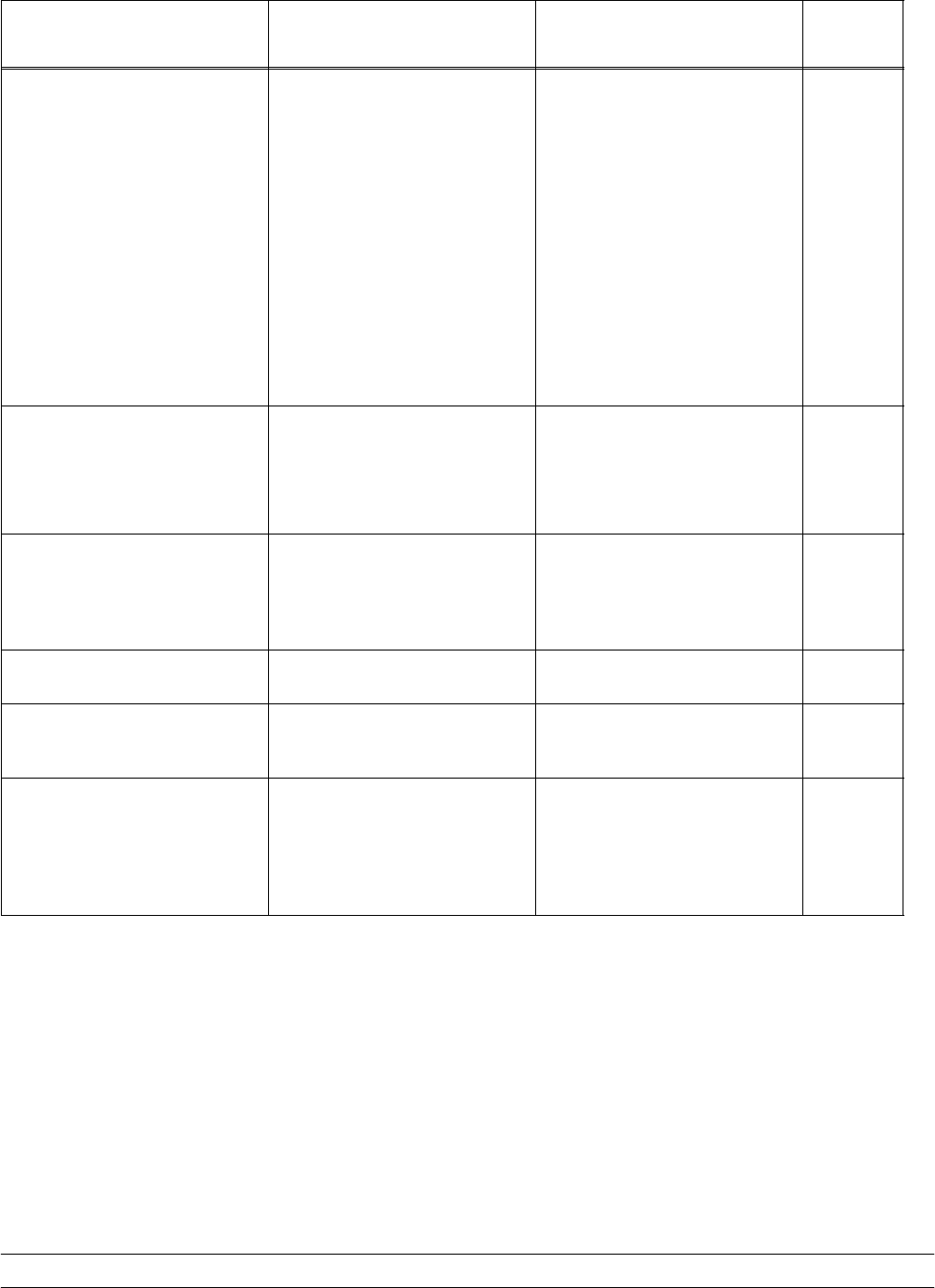

32

Models 8751/8754Troubleshooting Guide

PROBLEM PROBABLE CAUSE REMEDY PAGE

REF.

14. The piston travels back

and forth, but product is

not being pumped.

a. Inspect the check bands. a. Check bands must be

installed correctly, fit

tightly, and not have any

holes or lubrication. Make

sure check bands are not

inside-out.

-- -- --

b. Inspect the o-rings. b. O-rings must not be worn,

torn, or fit too loosely.

27

c. Check the pump c ylinder. c. The piston and liquid valve

body must be assembled

correctly and f it s nugly in

the pump c ylinder.

18

d. Missing or def ective

spring or poppet.

d. Replace.

19

15. E xcessive pump c ylinder

wear.

a. Inadequate or incorrect

lubrication of pump

cylinder.

a. Follow l ubrication

procedures carefully.

19

b. Incorrect ball crank

rotation.

b. Contact service

technician.

-- -- --

16. P itting occurring inside t he

pump cylinder.

a. Cleaner was l eft inside t he

pump cylinder.

a. After b rush c leaning the

pump cylinder, a llow it to

air dry. Follow

disassembly procedures

carefully.

26

17. The ball crank of the

motor r educer is broken.

a. Incorrect rotation of pump

motor.

a. Contact service

technician.

-- -- --

18. Too m uch pressure in t he

freezing c ylinder.

a. Plugged r elief hole in

liquid valve body below

poppet.

a. Clean.

-- -- --

19. Not enough pressure in

the freezing cylinder.

a. Weak or bent spring in

liquid valve body.

a. Replace.

-- -- --

b. Malfunctioning draw

switch.

b. Contact service

technician.

-- -- --

c. Missing poppet. c. Install the poppet.

19