19

Models 150, 152, 162, 168 Operating Procedures

120501

Assembly

Note: When lubricating parts, use an approved food

grade lubricant ( e xample: Taylor Lube).

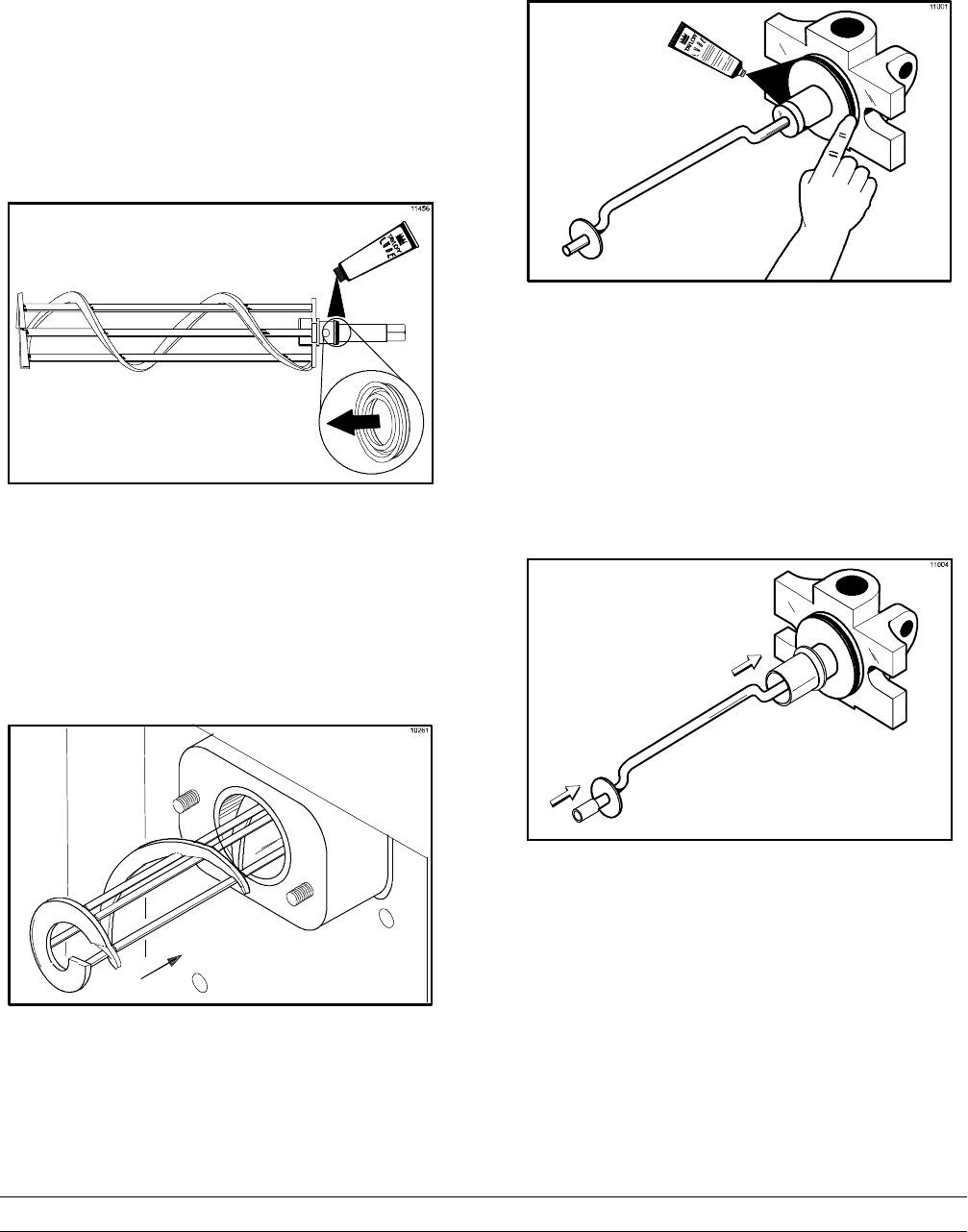

Step 1

Lubricate the groove on the beat er drive shaft. With the

opening of the cup seal facing away from the hex end,

slide the seal into the groove. Apply an even coat of

lubricant to the seal and the shaft. Do not

lubricate the hex end of the beater drive shaft.

Figure 15

Step 2

Insert the beater assembly through the rear shell

bearing at the back of the freezing cylinder and engage

the hex end firmly into the female socket. When

properly seated, the beater will not protrude beyond

the front of the freezing cylinder.

Figure 16

Repeat this step for the second freezing cylinder on

Models 162/168.

Step 3

Place the large o- ring(s) into the groove(s) on the back

of the freezer door and lubricate with Taylor Lube.

Figure 17

Step 4

Slide the front bear ing(s) ov er the baffle rod(s) s o the

flanged edge is against the door. Place the white

plastic guide bearing(s) on the end of the baffle rod(s).

Do not lubricate the front bearing(s) or the guide

bearing(s).

Figure 18

Step 5

Slide the slotted portion of the handscrews i nto the

slots in the freezer door.

Step 6

With both hands, hold the sides of the freezer door and

insert the baffle rod(s) into the center of the beater

assembly(ies). The white guide bearing(s) must fit

securely in the hole(s) of the drive shaft(s).