5

RLC-PRC016-EN

Features and

Benefits

Excellent Reliability

A building environment is expected to

be comfortable. When it is, no one says

a word. If it’s not… that’s a different

story. The same is true with chillers. No

one ever talks about chillers, yet alone

compressors, until they fail, and tenets

are uncomfortable and productivity is

lost. Trane’s helical rotary compressors

have a first year reliability rate of over

99%, which means our chillers stay

running when you need them.

Screw compressors were designed to

replace the inherent design flaws of a

reciprocating compressor. Trane’s helical

rotary compressor has successfully

achieved this goal, proven by the over

99% reliability rating of our compressor

in the first year of operation. A good

design like Trane’s should maintain this

level of reliability for several years of

chiller operation. Not all screw

compressors maintain a high reliability

and Trane is the only manufacturer that

will publish a reliability number. The

point is to make sure that you are getting

a reliable screw chiller design so that you

don’t end up with the downtime and lost

earnings that the industry is trying to

avoid by getting away from

reciprocating technology.

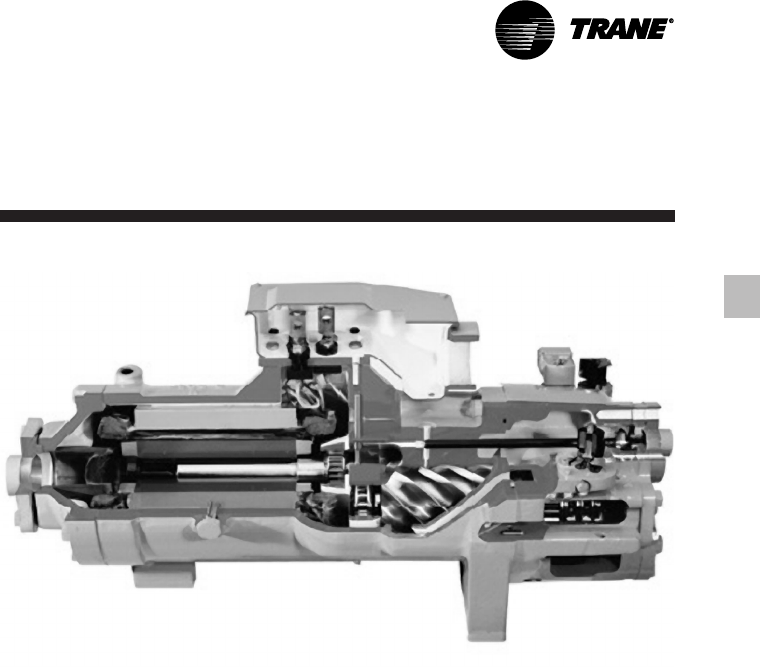

Fewer moving parts.

Trane’s helical

rotary compressors have only two major

rotating parts: the male and female rotor.

A reciprocating compressor can have

more than 15 times that number of

critical parts. Multiples of pistons,

valves, crankshafts, and connecting rods

in a reciprocating unit all represent

different failure paths for the

compressor. In fact, reciprocating

compressors can easily have a failure

rate four times that of a helical rotor.

Combine this with two to three

reciprocating compressors for each

helical rotary compressor on chillers of

equal tonnage, and statistics tell you it’s

a matter of time before you lose a

reciprocating compressor.

Robust parts.

Helical rotary

compressors are precisely machined

using state of the art processes from

solid metal bar stock. Tolerances are

maintained within a micron or less than

a tenth of the diameter of a human hair.

The resulting compressor is a robust yet

highly sophisticated assembly capable of

ingesting liquid refrigerant without risk

of damage. Contrast this to a

reciprocating compressor, which can be

destroyed by a single slug of liquid.

Series R

™

Compressor Highlights

• Direct-drive, low speed for high

efficiency and reliability.

• Simple design with only four moving

parts, resulting in high reliability and

low maintenance.

• Field serviceable compressor for easy

maintenance.

• Precise rotor tip clearance for optimal

efficiency.

• Suction gas-cooled motor, resulting in

lower operating temperatures for

increased motor life, and giving the

capability for:

• Five-minute start-to-start/two minute

stop-to-start capability, which allows

for closer water loop temperature

control.