7

RLC-PRC016-EN

Features and

Benefits

Superior Full Load Efficiency

Precise Rotor Tip Clearances

Higher energy efficiency in a helical

rotary compressor is obtained by

reducing the rotor tip clearances. This

reduces the leakage between high and

low pressure cavities during

compression. Precise rotor tip clearance

is achieved with the latest manufacturing

and machining technology. Trane is the

first helical rotary compressor

manufacturer to electronically check

compressor parts machining accuracy as

part of the standard production process.

Optimized Compressor Parts Profiles

Rotor and slide valves are unique

designs, optimized for the air

conditioning application. The rotors are

designed for the pressure ranges in the

air conditioning application. The unloader

valve has a unique profile that resulted

from computer performance modeling in

typical part-load situations.

Advanced Heat Transfer Surfaces

Condenser and evaporator tubes use the

latest heat transfer technology for

increased efficiency.

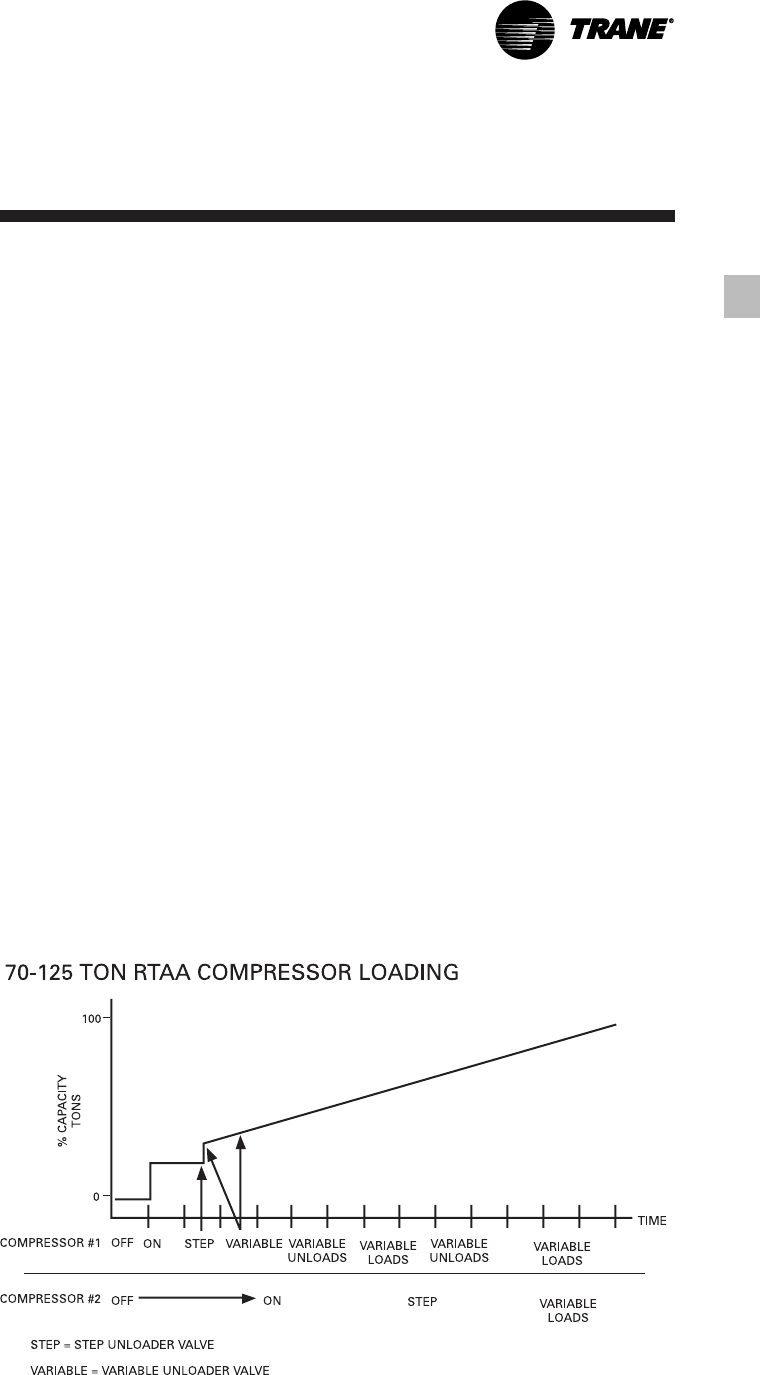

Great Part Load Efficiency

With Trane Helical Rotary

Screw Compressors and

Electronic Expansion Valve

Trane Helical Rotary Screw Compressor

Means Superior Part Load Performance

The air-cooled Series R

™

chiller has great

part-load performance. The combination

patented unloading system on the

“general purpose” compressor utilizes

the variable unloading valve for the

majority of the unloading function

similar to that of the slide valve. The

“general purpose” compressor also

uses a step unloader valve which is a

single unloading step to achieve the

minimum unloading point of the

compressor. The result of both of these

designs is optimized part-load

performance far superior to single

reciprocating compressors.

Optimum

Efficiencies