RLC-PRC016-EN8

Features and

Benefits

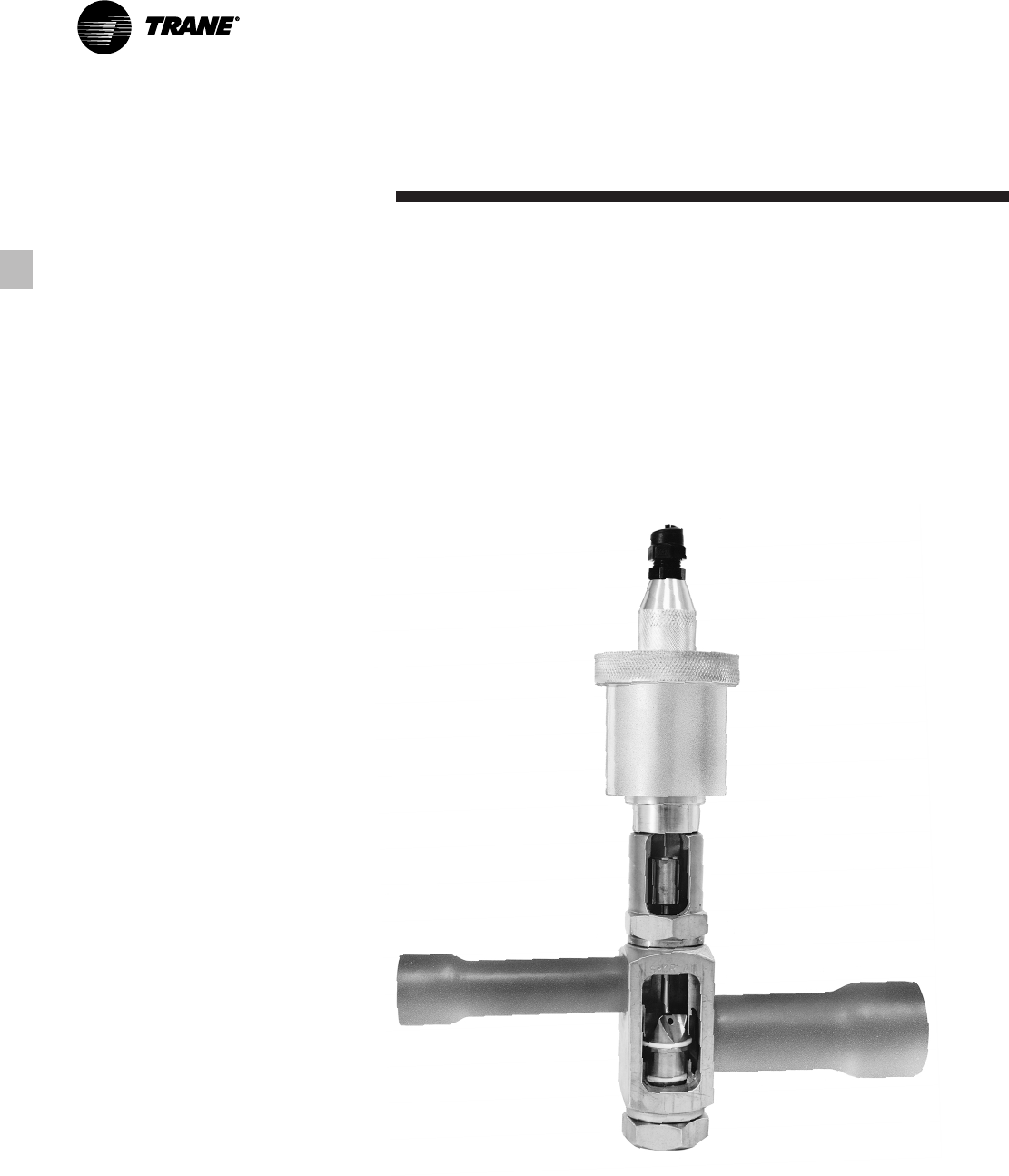

Electronic Expansion Valve

When coupled with Trane’s Adaptive

Control

™

microprocessor, our electronic

expansion valve significantly improves

part-load performance of the Series R

™

chiller by minimizing superheat in the

evaporator and allowing the chiller to

run at reduced condensing

temperatures. Chillers which use

conventional TXV’s must run at higher

head pressures and consume more

power than necessary at part-loads.

Additionally, the electronic expansion

valve and its controls allow much better

stability and control over dynamic load

and head changes. Under these

conditions a conventional TXV may

never achieve control stability and

extended periods of TXV “hunting” and

liquid slugging are common.

Capacity Control and Load Matching

Infinitely variable compressor

modulation allows the compressor

capacity to exactly match the building

cooling load. Reciprocating and screw

chillers that rely on stepped capacity

control must run at a capacity equal to or

greater than the load. Much of this

excess capacity is lost because

overcooling goes toward building latent

heat removal, causing the building to be

dried beyond normal comfort

requirements. The result is an increase in

chiller energy costs, particularly at the

part-load conditions at which the chiller

operates most of the time.

PID Chilled Water Setpoint

Control Through Slide Valve

Modulation

Maintain Chilled Water Supply Within

±

1

/2°F of Setpoint

Chillers that have step capacity control

typically can only maintain water

temperature to around ± 2°F. With the

air-cooled Series R

™

chiller, maintaining

temperature control has never been so

accurate.

Reduce Compressor Cycling

Modulating capacity control offers better

compressor reliability. Compressor

cycling, typical of reciprocating

compressors, will decrease compressor

component life. Parts like motors and

valves do not stand up well to excessive

compressor cycling.

Cutaway view of Trane’s electronic expansion valve.