INSTALLATION Flexible Pipe Installation.

FITTING THE APPLIANCE AND CABINET

It is recommend that a

3

/8", 1100mm long angled flexible hose (BFS), and a ½ " straight socket (BFS) be

used for the installation. However, any approved hose of the right length can be used.

IMPORTANT: Flexible tubing used must comply with BS 669 current editions. L.P.G. flexible

connections must be of a type suitable for L.P.G. and capable of operation up to 50mbar and carry a red

stripe, band or label.

NOTE: Only liquid sealants can be used in threaded gas connections. Do not use P.T.F.E. tape.

1 Make suitable arrangements for gas and electric supplies into the installation site. Preferably a junction

box or a 3 pin earthed socket should be situated at the back of the cabinet below the oven.

2 The electrical connection to the appliance is at the rear bottom right hand side, the junction box or socket

should be positioned accordingly.

3 Fit the cabinet as Fig.1, make sure that it is level.

4 When unpacking the appliance keep it on its polystyrene base until it is put into the cabinet to avoid

damage. Do not allow young children to play with any part of the packaging. After installation, please

dispose of the packaging with due regard to the environment, your local authority can arrange this.

NOTE:

It is imperative that the appliance is left in the base to protect both the appliance and the floor.

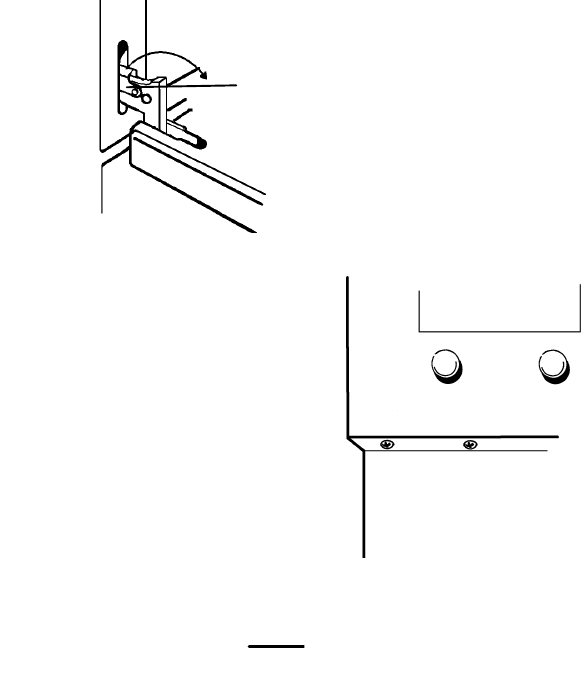

5 Open Oven door fully.

6 Rotate the hinge stirrups to there forward position see Fig.2.

7 To remove the door, clear the hinges by raising the door slightly whilst pulling towards you.

8 Remove the gas control knobs, springs, bezels and

timer control knobs.

9 Remove the four screws (two each side) which are

visible on the underside of the fascia. Fig. 3.

10 Tilt the bottom of the fascia panel out over. Withdraw

the fascia panel by moving it down over to disengage

from the top fixing lugs. Take care not to lose the two

rubber grommets from the timer.

NOTE: The thermostat and grill discs will remain attached

to the fascia panel. When refitting the control knobs and

bezels, the drive pins on the rear of the bezel must first be

located in the disc carrier. The knob and spring can now be

fitted onto the control spindle. To prevent the top of the

fascia panel mounts becoming slack, it may be necessary to

adjust the top fixing lugs.

11 If the gas supply bayonet and wall fixing bracket are to

be located behind the appliance it must be located in the shaded area as indicated in Fig.5.

39

Fig.3

HINGE

STIRRUP

Fig.2