November 1996 15 RS1200001

HFC134a Service Information

Replacement Service Compressor

HFC134a service compressors will be charged with

ester oil and pressurized with dry nitrogen. Before

replacement compressor is installed, pull out 1 rubber

plug. A pop from pressure release should be heard. If

a pop sound is not heard, do not use compressor.

Positive pressure in compressor is vital to keep

moisture out of ester oil. Do not leave compressor

open to atmosphere for more than 10 minutes.

Compressor Testing Procedures

• Refer to “Temperature and Relationship Chart” for

operating watts, test points, and temperature

relationship test.

• Temperature testing is accomplished by using 3 lead

thermocouple temperature tester in specific locations.

Test point T-1 is outlet on evaporator coil and T-2 is

inlet. Test point T-3 is suction tube temperature

midway between where armaflex ends and suction

port of compressor (approximately 12 inches from

compressor).

• Thermocouple tips should be attached securely to

specified locations.

• Do not test during initial pull down. Allow one off cycle

or balanced temperature condition to occur before

proceeding with testing.

• Refrigerator must operate minimum of 20 minutes

after thermocouples are installed.

• Turn control to colder to obtain required on time.

• Wattage reading must be recorded in conjunction with

temperature test to confirm proper operation.

• Suction and head pressures are listed on

“Temperature and Relationship Chart” Normally these

are not required for diagnosis but used for

confirmation on systems which have been opened.

Refrigerant Charge

Refrigerant charge in all capillary tube systems is

critical and exact amount is required for proper

performance. Factory charges are shown on serial

plate. Do not use refrigerant other than shown on

serial plate.

Leak Testing

Undetected leaks lead to repeated service calls and

eventually result in system contaminations,

restrictions, and burned out compressors.

After recharging, sealed system must be thoroughly

tested for leaks. If a very small leak is difficult to

isolate, coat area with soap suds and observe

location of bubbles.

To avoid death or severe personal injury, never

use oxygen, air or acetylene for pressure testing

or cleanout of refrigeration system. Use of

oxygen, air, or acetylene may result in violent

explosion. Oxygen may explode on contact with

oil and acetylene will spontaneously explode

when under pressure.

WARNING

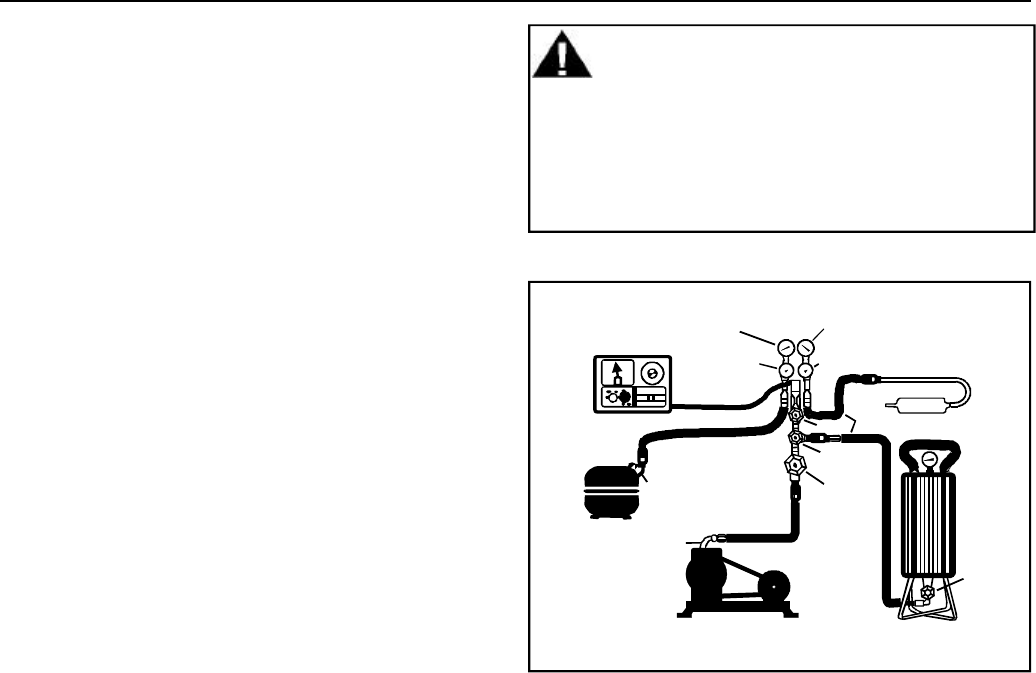

Evacuation and Charging

Vacuum Pump

.6 cm Copper

Tubing

Compressor

Compressor

Process

Tube

Charging Hose

Thermistor

Vacuum Gauge

Low Side Gauge

E

Valve

B

D

Valve

High Side Gauge

Charging Hose

Drier/Process Tube

F

Valve

Charging

Cylinder

C

A