VR8105, VR8205, AND VR8305 DIRECT IGNITION COMBINATION GAS CONTROLS

69-1226—2 4

CAUTION

Equipment Damage.

Can burn out valve coil terminals.

Never apply a jumper across (or short) the valve

coil terminals, even temporarily.

Follow the appliance manufacturers instructions if

available; otherwise use these instructions as a guide.

IMPORTANT

These gas controls are shipped with protective

seals over the inlet and outlet tappings. Do not

remove the seals until ready to install adapters

or connect the piping.

Converting Gas Control from Natural Gas

to LP Gas (or LP Gas to Natural Gas)

WARNING

Fire Or Explosion Hazard.

Can cause property damage, severe injury

or death.

1. Do not attempt to convert step-opening models

(suffix letter P).

2. Always change the main and pilot burner

orifices when converting from natural to LP gas

or from LP to natural gas. Carefully follow

appliance manufacturer specifications and

instructions to assure proper appliance

conversion.

3. Gas controls are factory-set for natural (and

manufactured) or LP gas. Do not attempt to

use a gas control set for natural

(manufactured) gas on LP gas, or a gas control

set for LP gas on natural (manufactured) gas.

Controls with standard, slow-opening, and two-stage

regulators (model numbers with suffix H, K, M, or Q) can

be converted from one gas to the other with a conversion

kit (ordered separately). See Table 4 for the correct

conversion kit.

Convertible Pressure Regulators

Controls with suffix letter R are convertible pressure

regulator models. They can be converted from natural

gas to LP gas or from LP gas to natural gas without a

conversion kit.

Before converting the control from one gas to another,

check the control label and the appliance manufacturer’s

rating plate to determine if the pressure regulator setting

(factory set) will meet the appliance manifold

requirements after conversion.

NOTE: Convertible pressure regulator models (suffix

letter R) do not have field-adjustable regulators.

If the factory pressure regulator setting meets the

appliance manifold requirement, convert the control as

follows:

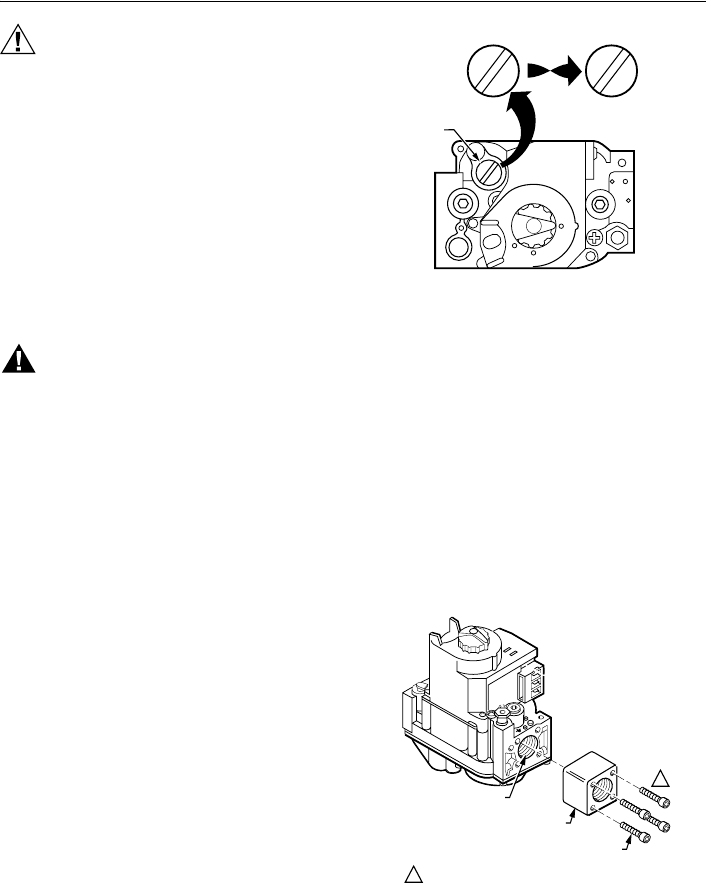

1. Remove the pressure regulator cap, Fig. 1.

2. Invert the cap so that the letters appear that

represent the gas type appropriate for the

appliance. NAT for natural manufactured gas, LP

for liquid petroleum gas.

3. Replace the cap and tighten firmly.

Fig. 1. Top view of convertible pressure regulator

cap.

Install Adapters To Control

If adapters are being installed on the control, mount them

as follows:

Flanges

1. Choose the appropriate flange for your application.

2. Remove the seal over the ignition system control

inlet or outlet.

3. Make sure that the O-ring is fitted in the groove of

the flange. If the O-ring is not attached or is

missing, do not use the flange.

4. With the O-ring facing the gas control, align the

screw holes on the control with the holes in the

flange. Insert and tighten the screws provided with

the flange. See Fig. 2. Tighten the screws to 25

inch-pounds of torque to provide a gas-tight seal.

Fig. 2. Firmly fasten flange to valve, but do not

overtighten screws.

Bushings

1. Remove the seal over the control inlet or outlet.

2. Apply a moderate amount of good quality pipe

compound to the bushing, leaving two end threads

bare. On an LP installation, use compound that is

resistant to LP gas. Do not use Teflon tape.

3. Insert the bushing in the control and carefully

thread the pipe into the bushing until tight.

P

RESSURE

R

EGULATOR

C

AP

M1167

8

N

A

T

N

A

T

L

P

L

P

N

A

T

N

A

T

OR

OTHER SID

E

OF CAP

M904

6

VALVE OUTLET

FLANGE

9/64 INCH HEX SCREWS (4)

DO NOT OVERTIGHTEN SCREWS. TIGHTEN TO

25 INCH-POUNDS.

1

1

69-1226-2.fm Page 4 Thursday, November 13, 2003 12:50 PM