VR8105, VR8205, AND VR8305 DIRECT IGNITION COMBINATION GAS CONTROLS

9 69-1226—2

4. With main burner operating, check the gas control

flow rate using the meter clocking method or check

pressure using a manometer connected to the

outlet pressure tap on the gas control. See Fig. 6.

5. If necessary, adjust the high pressure regulator to

match the appliance rating. See Tables 8 and 9 for

factory-set nominal outlet pressure and adjustment

range.

a. Remove the pressure regulator adjustment cap

(Fig. 6).

Using a screwdriver, turn the inner adjustment screw for

HI pressure clockwise to increase or

counterclockwise to decrease the gas pressure

to the burner.

6. After high pressure has been checked, check low

pressure regulation. Two-stage appliance

operating sequences vary. Consult the appliance

manufacturers instructions for the specific

operating sequence and regulator adjustment

procedure for the appliance in which the control is

installed and for instructions on how to prevent the

control from moving to high stage while checking

the low pressure regulator setting.

7. Check the low rate manifold pressure listed on the

appliance nameplate. Gas control low rate outlet

pressure should match this rating.

8. With main burner operating, check the gas control

flow rate as before (using the meter clocking

method or check pressure using a manometer

connected to the outlet pressure tap on the

control).

9. If necessary, adjust the low pressure regulator to

match the appliance rating. See Tables 8 and 9 for

factory-set nominal outlet pressure and adjustment

range.

a. Remove the pressure regulator adjustment cap

(Fig. 6).

Using a screwdriver, turn the inner adjustment screw for

LO pressure clockwise to increase or

counterclockwise to decrease the gas pressure

to the burner.

10. Once high and low pressure have been checked

and adjusted, replace pressure regulator

adjustment cap. If the desired outlet pressure or

flow rate cannot be achieved by adjusting the gas

control, check the control inlet pressure using a

manometer at the inlet pressure tap of the control.

If the inlet pressure is in the nominal range (see

Tables 8 and 9), replace the gas control.

Otherwise, take the necessary steps to provide

proper gas pressure to the control.

Check Safety Lockout (Slow-Opening

Controls Only)

1. With the system power off and the thermostat set

to call for heat, manually shut off the gas supply.

2. Energize ignition control and start timing safety

lockout time. When spark ignition terminates, stop

timing.

When using the VR8105H, VR8205H and

VR8305H step-opening control, the specified

ignition control safety lockout time must exceed 8.5

seconds for the system to function properly.

3. After spark cutoff, manually reopen the gas control

knob. No gas should flow to the main burner.

4. Reset the system by adjusting the thermostat

below room temperature, wait 30 seconds, and

then move the thermostat setting up to call for

heat. Normal ignition should occur.

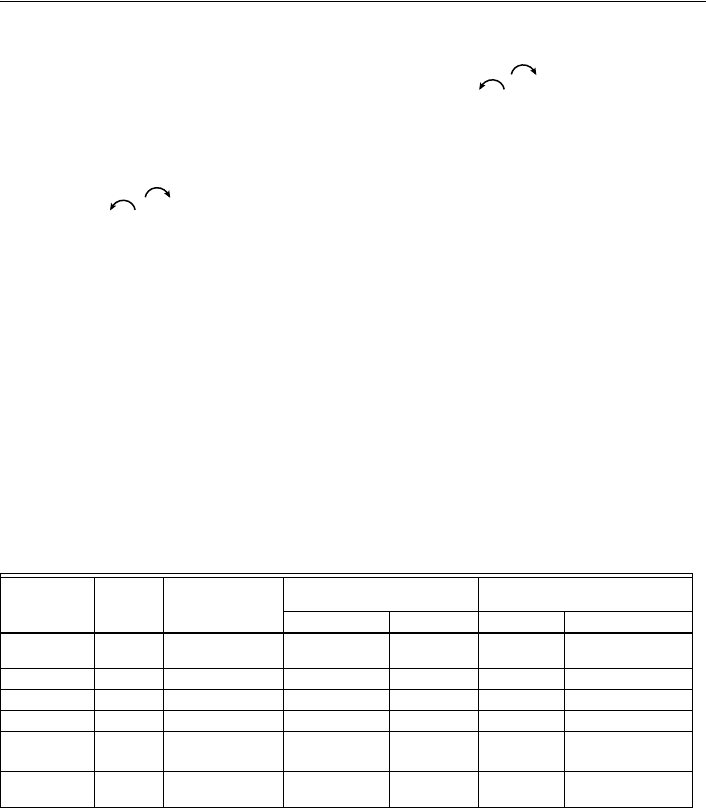

Table 8. Pressure Regulator Specification Pressures (in. wc).

a

Low Fire setting range for VR8305Q 1/2 in. by 1/2 in. and 1/2 in. by 3/4 in. is 1.5 to 3.0 in. wc.

Model Type

Type of

Gas

Nominal Inlet

Pressure Range

Factory Set Nominal Outlet

Pressure Setting Range

Step Full Rate Step Full Rate

Standard,

Slow

NAT 5.0-7.0 — 3.5 — 3.0-5.0

LP 12.0-14.0 — 10.0 — 8.0-12.0

Step NAT 5.0-7.0 0.9 3.5 None 0.7-1.7

LP 12.0-14.0 2.2 10.0 None 1.4-5.5

Two-stage NAT 5.0-7.0 — 1.7 Low

3.5 High

—

0.9-3.0 Low

a

3.0-5.0 High

LP 12.0-14.0 — 4.9 Low

10.0 High

— 3.5-5.5 Low

8.0-11.0 High

69-1226-2.fm Page 9 Thursday, November 13, 2003 12:50 PM