136

10

10

CRANKSHAFTS AND CAMSHAFTS

Remove Crankshaft and Camshaft

1. Drain oil from engine and all fuel from fuel

tank. Drain oil from gear reduction unit (if

equipped) and remove from engine

(A, Figure 1).

2. Remove blower housing/rewind assembly

and flywheel/fan assembly.

3. Remove burrs and clean crankshaft, then

remove crankcase cover or sump. Set

aside.

NOTE: If crankcase cover or sump sticks, tap

lightly with soft hammer on alternate sides near

dowel pins (B). It is not necessary to remove

dowel pins.

Figure 1

4. Carefully tip engine with PTO-end facing

up.

5. Rotate crankshft until timing marks

(A, Figure 2) are aligned. With camshaft in

this position, the valve tappets will remain

clear of cam lobes. Lift out camshaft (B).

Figure 2

6. Rotate crankshaft to place piston at Top

Dead Center (TDC).

7. Remove connecting rod cap, then slide out

crankshaft.

Inspect

Check Crankshaft

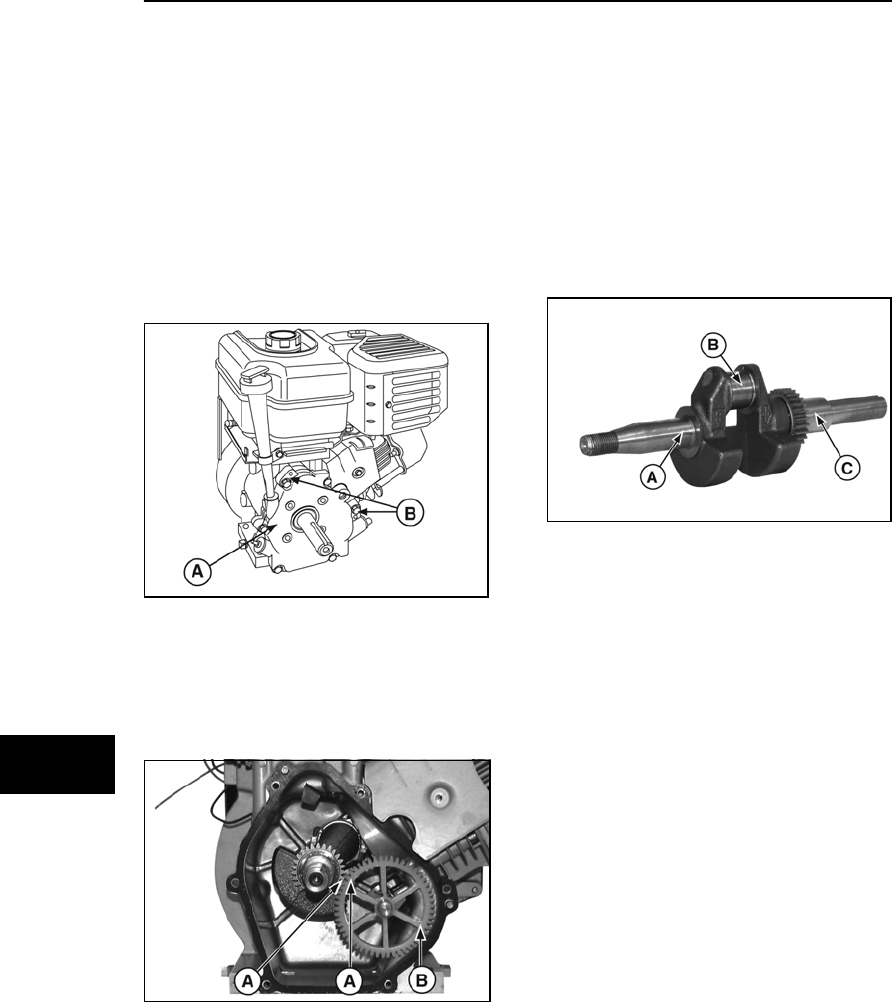

1. Inspect crankshaft for scoring on mag

journal (A, Figure 3), crankpin journal (B),

and PTO journal (C). Replace crankshaft

is scoring is found or if crankshaft is bent.

DO NOT attempt to straighten bent

crankshafts.

Figure 3

2. Using a dial caliper, measure the journal

diameters and balancer eccentrics (if

equipped). Compare results to values

listed in Section 12 - Engine

Specifications. If wear exceeds the reject

dimensions, replace the crankshaft.

Check Camshaft

1. Check gear (A, Figure 4) for worn or

damaged teeth. Check lobes (D) and

journals (B, C) for scratching or scoring.

Check compression release mechanism

(A, Figure 5) for wear, burrs, or sticking.

Replace camshaft if any of these

conditions are found.