70

4

4

Inspect and Clean Carburetor Components

1. Inspect openings in the carburetor body

for evidence of wear or damage. If found,

replace the entire carburetor assembly.

2. Inspect the choke shaft, choke valve,

throttle shaft, and throttle valve for

evidence of wear or damage. Replace

parts as necessary.

3. Using Carb/Choke Cleaner #100041 or

#100042, thoroughly clean the following

components, then follow with compressed

air to dry:

• Passages in the fixed main jet (bowl nut)

• Inside and outside of the fuel bowl

• Float

• Choke shaft and choke valve

• Throttle shaft and throttle valve

• All passages, openings, and the inside

and outside of the carburetor body

NOTE: Do not soak non-metallic components,

such as floats, o-rings, seals, or diaphragms, in

carb/choke cleaner or they will be damaged.

4. If any passages remain plugged after

cleaning, replace the component or the

entire carburetor assembly.

Assemble Carburetor

Consult the Illustrated Parts List to obtain the

appropriate carburetor overhaul kit before

reassembling the carburetor.

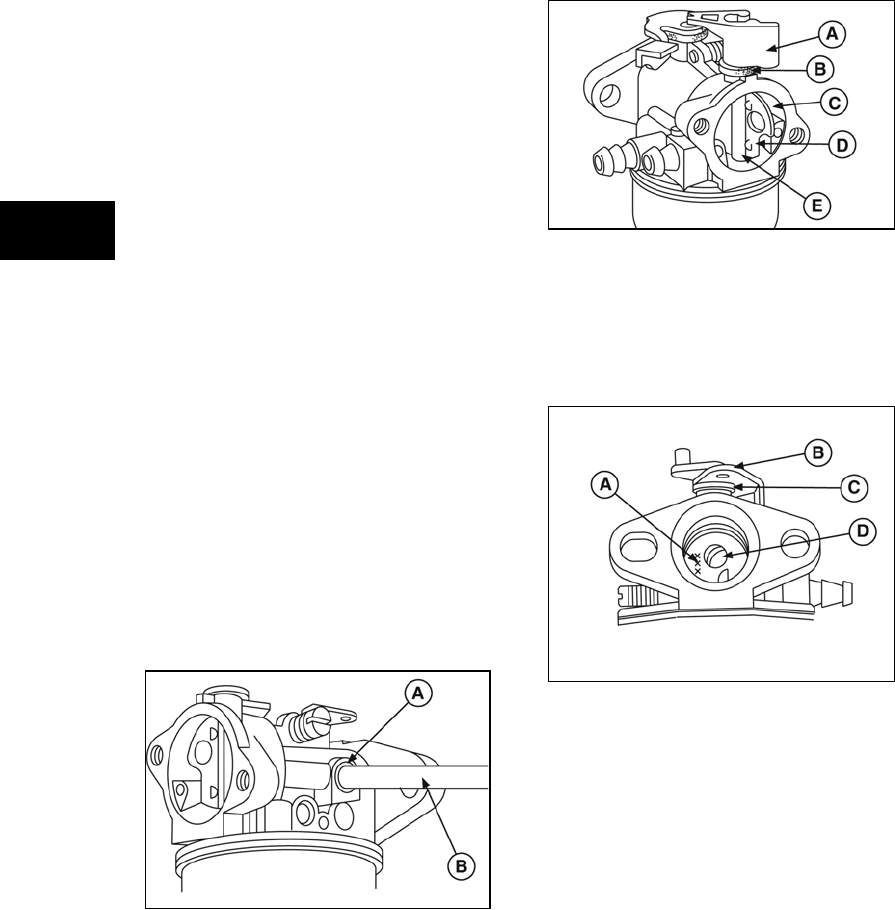

1. Install new Welch plug (A, Figure 17) with

a pin punch (B) of slightly smaller

diameter than the plug. Press against the

plug until it is flat in the carburetor

opening. Do not cave in the plug. Seal the

edge of the plug with a non-hardening

sealant.

Figure 17

2. Install new foam seal (B, Figure 18) on

choke shaft (E), then slide shaft into

carburetor body (C). Rotate shaft

clockwise (A), and insert choke valve into

slot until centered, with dimples (D)

positioned as shown. Actuate the choke

shaft to check for proper movement.

Figure 18

3. Install new foam seal (C, Figure 19) on

throttle shaft (B), then slide shaft into

carburetor body. Rotate shaft until flat is

facing out. Position throttle valve on flat

with numbers facing out (A), then install

screws (D). Actuate the throttle shaft to

check for proper movement.

Figure 19

4. Install idle speed screw and spring. Install

idle mixture screw and spring with a new

limiter cap, if equipped.

5. Using Bushing Driver #19057

(A, Figure 20), install new needle seat with

grooved edge down (B) until firmly seated.