Page 25

Removal and Replacement:

1. Disconnect the red leads from the overflow pro-

tection switch from the black wire from the termi-

nal block and the blue wire from the thermostat.

2. Remove the nut beneath the copper overflow cup.

3. Remove the entire switch assembly from the cup.

4. Place the new switch assembly into the cup, wires

first. Make sure that a gasket is in place around the

threaded switch stem.

NOTE - The magnets must be at the top of float and

there must be NO adjusting washers installed for

the overflow protection switch to operate prop-

erly.

5. Install the nut beneath the copper overflow cup. Be

sure not to overtighten.

6. Refer to Fig. 17 when reconnecting wires.

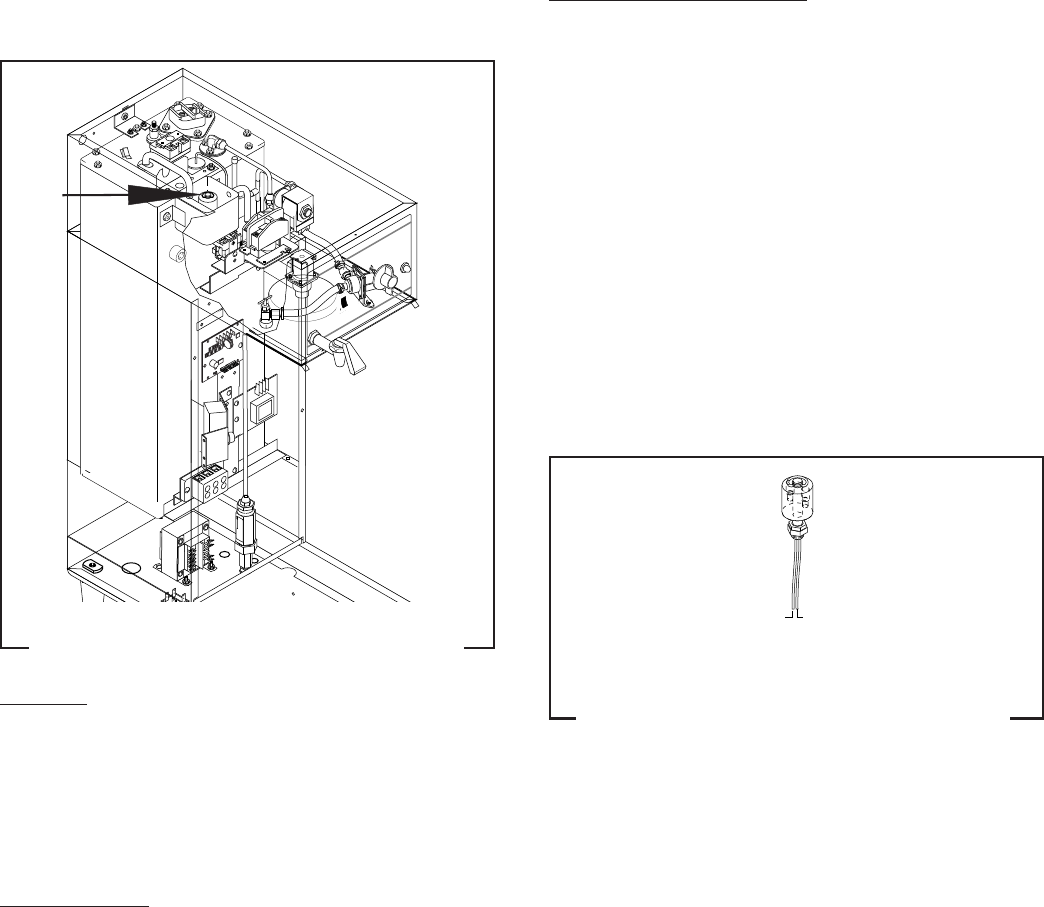

OVERFLOW PROTECTION SWITCH

SERVICE (cont.)

Location:

The overflow protection switch is located inside

the hood on the tank inside the copper overflow cup.

To test the overflow protection switch, access will

also be needed to the level control board and terminal

block.

Test Procedure:

1. Disconnect the brewer from the power source.

2. Remove the wire nuts connecting the red wires

from the overflow protection switch to the black

wire from the terminal block and blue wire from the

thermostat.

3. Check for continuity across the overflow protec-

tion switch red wires only until the plastic float is

raised and check that continuity returns when the

plastic float is again lowered.

If continuity is present as described, reconnect the red

wires to the black wire from the terminal block and the

blue wire from the thermostat.

If continuity is not present as described, replace the

overflow protection switch.

P834

FIG. 16 OVERFLOW PROTECTION SWITCH

FIG. 17 OVERFLOW PROTECTION SWITCH

LEADS

22978.0000

TL5

TL4

TL3

TL2

TL1

J2

J

1

S

E

T

L

O

C

K

LOCK

SET

1

2

3

4

5

6

1 2 3 4 5 6

BUNN

90 psig max operating pressure

Strainer/Flow Control # 22300.033 0

(Repl. Flow Washer #20526.0330)

(Repl. Screen #23721.0000)

.500 gpm FLOW

P2230

RED to BLU Lead

from Thermostat or to

VIO Wire from Electronic

Control Assy

RED to BLK Wire from

Terminal Block

28230 092200