Page 27

SERVICE (cont.)

ELECTRONIC CONTROL ASSEMBLY (cont.)

P924

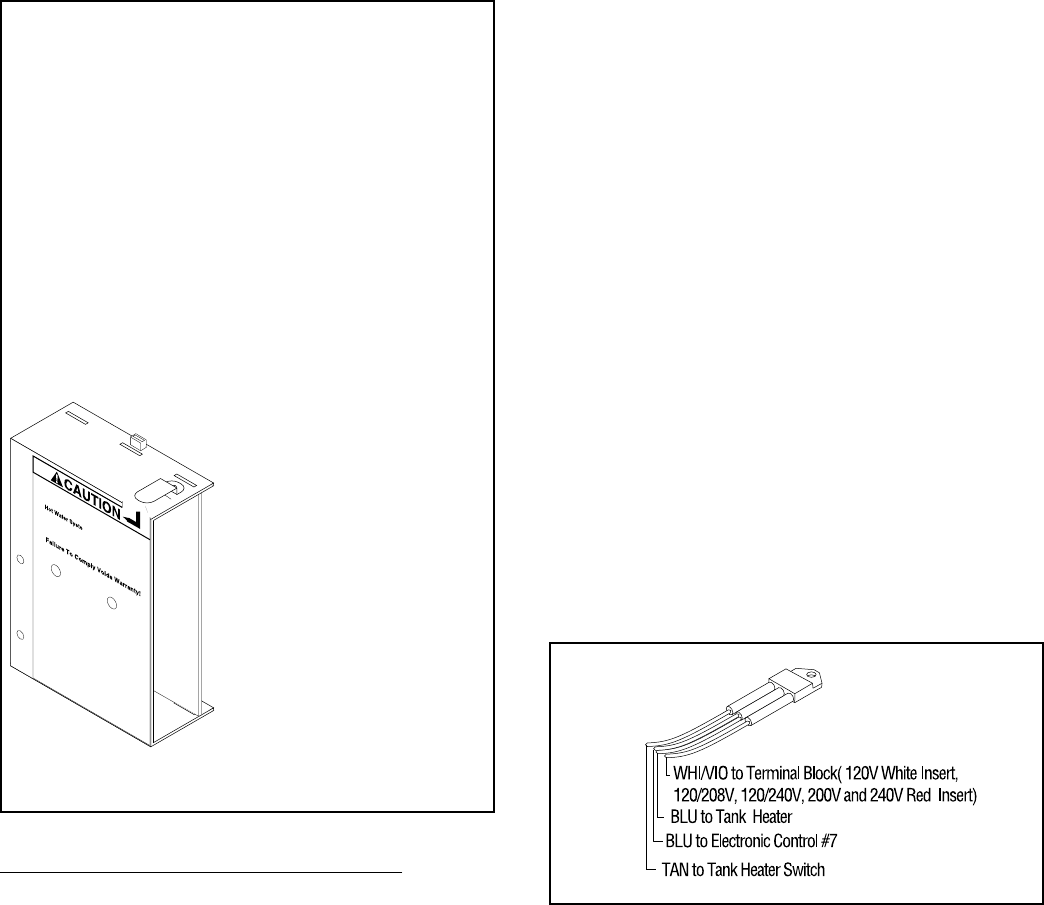

Triac Assembly Removal and Replacement

NOTE - each triac installation requires the use of an

approved silicone heat sink compound. Bunn-O-

Matic recommends the use of Dow Corning 340

compound or equivalent. It can be purchased direct

from Bunn-O-Matic (part number M2522.0002).

1. Place the tank heater switch on the electronic

control assembly in the “OFF” position.

2. Completely drain the tank.

3. Place a stryofoam or wood block between the

center of the tank and the rear of the brewer.

4. Disconnect triac wires, white/violet from terminal

block, blue from tank heater, blue from electronic

control and tan from tank heater switch.

5. Carefully set the brewer on its back.

6. Remove the 2" dia hole plug from the bottom

cover.

7. Remove the two #8-32 keps nuts securing tank to

tank mounting bracket.

8. Remove the twelve #8-32 slotted head screws

securing the bottom cover.

9. Remove the bottom cover with the four feet, the

tank mounting brackets, triac/heat sink as an

assembly.

10. Remove triac/heat sink from tank mount

ing bracket and discard.

11. Install new triac/heat sink assembly on

tank mounting bracket.

12. Route the wires up around the rear of the

brewer.

13. Reinstall the bottom cover, four feet, tank

mounting brackets and triac/heat sink to the

bottom of the tank using two #8-32 keps nuts.

14. Secure bottom cover to brewer base with

twelve #8-32 slotted head screws.

15. Stand the brewer upright.

16. Reconnect the wires of the new triac assembly.

Refer to the illustration below when reconnect-

ing wires.

P923