3-27

Improperly sized or installed paper will also allow food particles and sediment to pass through and

clog the suction tube on the bottom of the filter carriage. Particles large enough to block the suction

tube may indicate that the crumb tray is not being used.

Pan blockage can also occur if shortening is left in the pan and allowed to solidify. The heater strip

on the suction tube is designed to prevent solidification of residual shortening left in the tube. It will

not melt or prevent solidification of shortening in the pan.

Blockage removal can be accomplished by forcing the item out with an auger or drain snake.

NEVER use compressed air or other pressurized gases to force out the blockage.

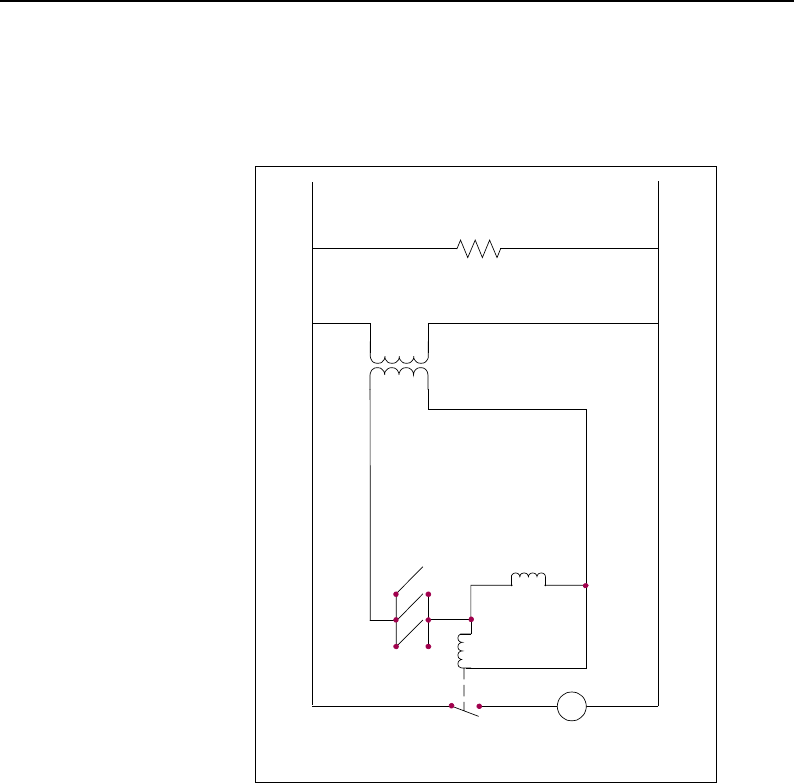

The electronics of the FootPrint III system are simple and straightforward. Microswitches, attached

to handles for each vat and wired in parallel, provide the 24VAC required to activate the pump relay

coil when the handles are moved to the ON position. The activated pump relay coil pulls in the

pump motor switch, supplying power to the pump motor.

Pump Relay

Coil

Micro-

switches

Pump Motor Switch

Pump Motor

Solenoids

(Redesigned

Models Only)

24VAC

Line VAC

FootPrint III Simplified Wiring Diagram

All Heater Tapes (Original and Redesigned Models)

(Heater Tapes have been removed from

oil return lines in Redesigned Models)

M

For FootPrint III systems built before August 1997, all heater tapes are wired directly into the line

VAC source. They remain energized as long as the unit is plugged in. In systems built in August

1997 and later, oil return line heater tapes have been eliminated. In these units, the only heater tape

used is on the suction tube and pump. This tape is still wired directly into the line voltage. A pair of

vacuum-breaking solenoids is wired into the 24VAC circuit.

The redesigned FP III is distinguished from original-design units by the absence of casters on the

filter base assembly. The redesign incorporated an improved oil return system that allows