1-28

The oil return line heater tapes in the Filter Magic system are wired directly into the line VAC

source and remain energized as long as the unit is plugged in. The filter pan suction tube heater

tape, however, is wired into the 24 VAC circuit. The suction tube tape is activated only when the

filter pan is positioned all the way to the rear of the cabinet, allowing a pair of “bullet” contactors

mounted on the pan to touch a corresponding pair of contactors mounted on the cabinet frame.

For FootPrint III systems built before August 1997, all heater tapes are wired directly into the line

VAC source. They remain energized as long as the unit is plugged in. In systems built in August

1997 and later, oil return line heater tapes have been eliminated. In these units, the only heater tape

used is on the suction tube and pump. This tape is still wired directly into the line voltage. A pair of

vacuum-breaking solenoids is wired into the 24 VAC circuit.

In units built from August 1997 onward, the oil return system allows oil to drain back to the filter

pan when the filter system is turned off, eliminating the need for most heated oil return components.

For a short time, one-piece, welded oil return manifolds were used. The one-piece manifolds have

been replaced with Dormont stainless steel flexlines and nipples and are no longer available.

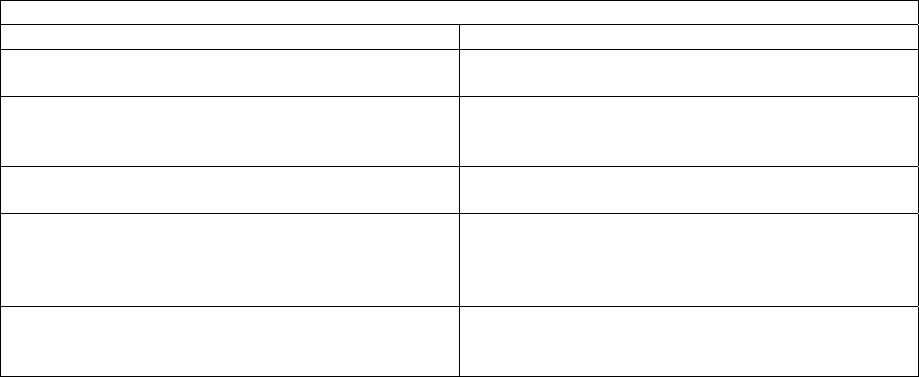

PRE-AUGUST 1997 VS CURRENT DESIGN FP-III FILTRATION SYSTEM

Original System Redesigned System

Return lines and manifolds wrapped with silicone

strip heaters and aluminum tape.

No heater strips or aluminum tape on return

lines.

Filter base assembly connected to unit with a

black, heated return hose beneath the filter.

Non-heated Teflon hose with a swivel joint con-

nects the filter base assembly to the unit above

the filter.

Filter base assembly equipped with swivel cast-

ers.

Filter base assembly has no casters.

Operator-removable filter base assembly. (Filter

base assembly stoplocks in cabinet can be ro-

tated to remove tray.)

Filter base assembly is not removable except by

a qualified service technician. (Filter base as-

sembly stoplocks fitted with a screw and nut to

prevent filter removal.)

Oil remains in return lines when filter system is

turned off.

Oil gravity-drains back to the filter pan when filter

system is turned off, leaving no oil or shortening

in return lines.

Power Shower Sub-System

A solenoid vent valve is mounted on the left end of the front oil return assembly. It prevents

vacuum-lock of the system as oil drains back to the filter pan when the unit is turned off. The

solenoid valve is connected to the square drain sub-system by a clear ⅜” O.D. Teflon tube and

threaded fittings. Stainless steel Dormont flexlines connect the manifolds to the valves. Standard

½” X ½” X 90º black metal street elbows are used to make the connections.

A 22-inch Dormont stainless steel flexline, running above the filter assembly, connects the front oil

return assembly to the rear manifold.

Filter Base Assembly and Pump Sub-System

Casters have not been used on filter base assemblies built since August 1997. When the casters were

eliminated from the filter base assembly, the assembly was redesigned to prevent it from being taken

out of the cabinet without removing a set of machine screws and nuts.

A new Teflon hose with a braided stainless steel covering connects the pump to the rear manifold

and replaces the heated hose running from the pump discharge under the unit to the Power Shower