H50 SERIES GAS FRYERS

CHAPTER 1: SERVICE PROCEDURES

1-1

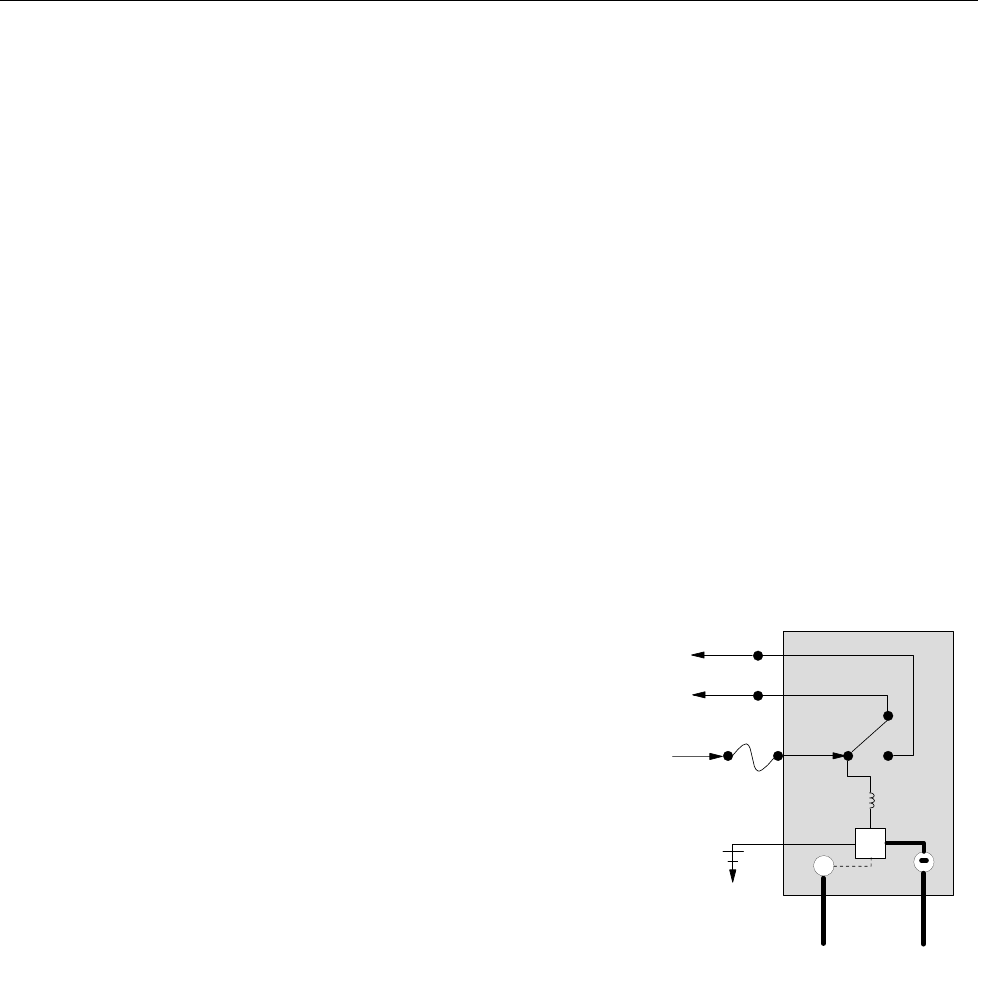

Inside the Ignition Module

TD

Out to

Gas Valve

To Alarm

25 V +

GND

HV

Ignition Wire Flame Sensor

Coil

1.1 Functional Description

H50 Series fryers contain a welded stainless steel frypot that is directly heated by a high efficiency

infrared burner system requiring approximately 43% less energy than conventional burners to cook

the same volume.

Self-contained combustion chambers (referred to as “burners”) are fitted into rails attached to the

sides of the frypot, one on each side. Each combustion chamber is fitted with special ceramic tiles

that are heated by the burning of a forced air/gas mixture. The tiles transfer their heat to the frypot

by means of infrared radiation, providing much more constant and uniform heat dispersion over the

surface of the frypot than do conventional burners. Because less heat is lost to the atmosphere in the

process, compared to “open-burner” designs, less fuel is required to achieve and maintain a given

frypot temperature.

In full vat units, gas flow to both of the burners is regulated by one electromechanical gas valve. In

dual vat units, each burner has its own valve. All fryers in this series are equipped with 24VAC gas

valve systems, and all are configured with electronic ignition.

THE ELECTRONIC IGNITION SYSTEM

An ignition module mounted in the component box or

“shield” (located behind the control panel) is connected to

an ignitor assembly at the burner. The ignition module

performs four important functions: it provides fuse

protection for the 24-volt circuit, provides an ignition

spark, supplies voltage to the gas valve, and proofs the

burner flame. The module contains a 4-second time delay

circuit and a coil that activates the gas valve. Three types

are in use. A closed-box design is used in most fryers, but

in some fryers built for export the module resembles an

interface board. A single dual-spark module is used on

current production full-vat fryers. Two single-spark

modules were used on full-vat fryers built before August

2000. All dual-vat fryers use two single-spark modules.

The ignitor assembly consists of a spark plug, an enrichment tube, and a flame sensor.

At start-up, the power switch is placed in the ON position, supplying approximately 12-volts DC to

the heat control circuitry in the controller or computer and to one side of the heat relay coils on the

interface board. If resistance in the temperature probe indicates the temperature in the frypot is

below 180ºF (82ºC), the current flows through a melt cycle circuit where a timer switch alternately

closes for 6 seconds and opens for 24 seconds. If the temperature is 180ºF (82ºC) or above, the

current flows through a heat circuit, bypassing the timer switch. In either case, ground is supplied

to