Part # 4517957 Rev. 13 (02/10/11)Page 14

MAINTENANCE & CLEANING continued

Convection Oven

1. Open the lower kick panel.

2. Remove the left & right hand oven door springs. USE

CAUTION: the oven door will need additional support to

remain closed.

3. Remove the left and right hand radiation shields.

4. Remove the two (2) screws that secure the pilot bracket

and disconnect the pilot tubing at the union connection.

5. Remove the injector support and slide the burner and

burner pan forwards out of the combustion chamber.

6. Clean the burner with a sti scrubbing brush and shake

the burner well to ensure that ports are clear of any

debris.

7. Reassemble in the reverse order.

Pilot Burner Cleaning

1. Remove the main burners (refer to the section on main

burner cleaning).

2. Disconnect the pilot gas supply pipe from the pilot jet.

3. Remove the pilot jet.

4. Clean by blowing through or washing. Do not use wire to

clear the pilot jet.

5. Reassemble in the reverse order.

Gas Valve

Re-greasing of the gas taps is not recommended. If the

tap spindle becomes seized or dicult to turn, refer to

Replacement of Parts section in this manual.

Thermostat Calibration

Oven

It is normal for a hydraulic thermostat cycling with a

temperature dierential of 45° to 50°F. If the thermostat

is cycling beyond the 15° tolerance above or below the

set point and the appliance is under warranty, recalibrate

the thermostat or if not under warranty, consult owner for

proper action. If the thermostat is out of calibration more

than 50°, it will not likely hold an attempt of recalibration. We

suggest that the thermostat be replaced.

1. Place the thermocouple of the test instrument in the

center of the oven.

2. Turn the oven temperature control dial to 400°F. In order

to allow the oven temperature to stabilize, the oven

control must be allowed to cycle twice before taking a

test reading.

3. Check the temperature reading just when the control

cycles “OFF” as indicated by cycling pilot lamp. If the

temperature does not read within 15°F of the dial setting,

recalibrate as follows:

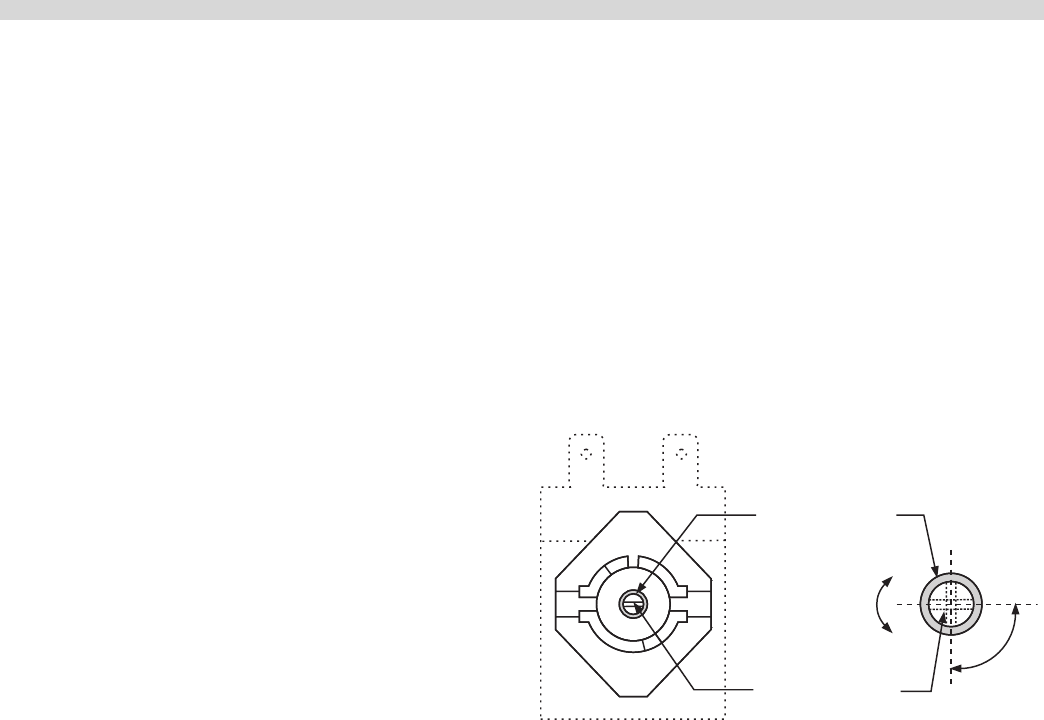

4. Carefully remove the thermostat dial, not disturbing the

dial setting.

Decrease

Increase

"A" Calibration

Screw Head

"B" Dial Shaft

1/4

Turn

5. Hold the thermostat shaft steady and with a small at

blade screw driver, turn the calibration screw located

inside the shaft clockwise to decrease the temperature

and anti-clockwise to increase the temperature. Note:

Each 1/4 turn of the screw will create a change of

approximately 25°F.

6. Replace the thermostat dial and repeat steps 1 through 3

to verify that correct adjustment has been made.

Griddle

1. Use a test instrument with a special disc type

thermocouple or a reliable surface type pyrometer. Note:

a drop of oil on the face of the disc will provide better

contact with the plate.

2. Set all griddle thermostats to 300°F. In order to allow the

griddle temperature to stabilize, the thermostats must be

allowed to cycle twice before taking a test reading.