—

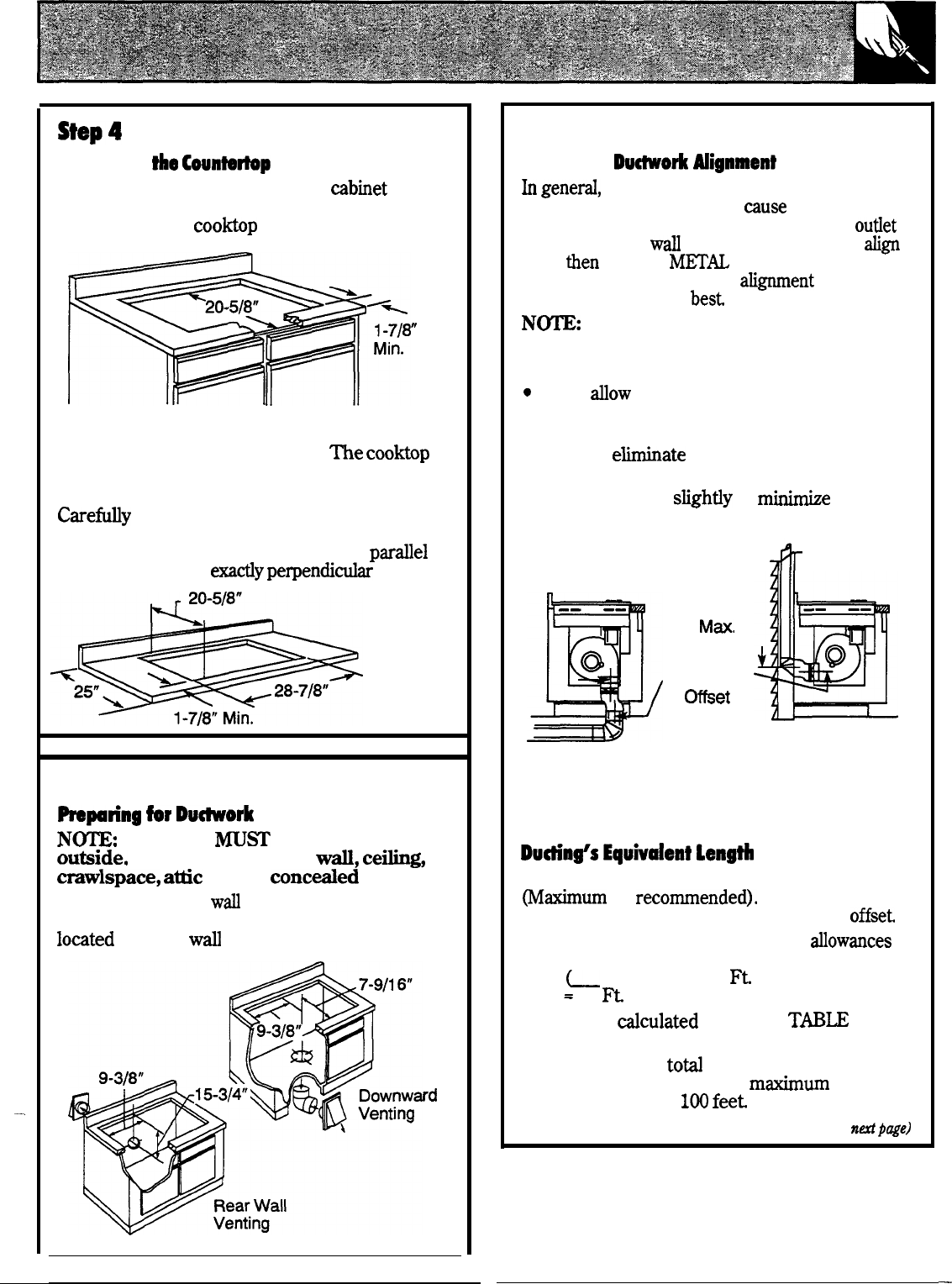

Step4

Preparing

he

Counte~p

Clearance

between inside front of

abinet

and

rear of countertop cutout must be 2&A” in order

to accommodate

cooktop

depth.

w

A 1/2” wide flat area is required around the edge

of opening for support of the unit.

me

cooktop

unit must be level and sit squarely into

countertop opening.

CarefuUy

cut countertop opening according to

the dimensions shown in the frustration. Be sure

that opening is cut squarely, with sides

parflel

to

each other and rear

exatiy

perpenditi

to sides.

Step 5

~pating

hr

DuWork

N~:

Ductwork

~fl

be vented to

ou~ide.

DO NOT vent into a

-,

ce~,

crawlspace,

atic

or any

concded

space.

Cut

hole in cabinet

wd

or floor as appropriate

for your initiation. Make sure exhaust duct is

lo=ted

between

wd

studs or floor joists.

rd

Step 5A

Blower to

Du-ork

Nignment

h

gened,

the use of flexible ducting is

discouraged because it can

muse severely

restricted airflow. However, if the blower

outiet

and the floor or

wa~

duct location do NOT

tign

well,

tien

flexible

M~X

ducting can be used

to adapt to an offset. Good

atignrnent

without use

of flexible ducting is

best

N~:

. Do not exceed the maximum recommended

offset of 3“.

c

Do not

dow

the

flexible ducting to kink or

collapse.

. Do stretch the flexible ducting as much as

possible to

etiate

as much of the corrugation

as possible.

● Do rotate blower

stightiy

to

~e

off-set

(see step 6).

3“

Ma.

Centerline

to

Centerline

Met

Bottom Venting

Back Venting

Steps to Determine Flexible

Duting’s

Equtialent

Lengti

1.

Measure the

actual amount of offset

m-urn

3“

recornrnended).

The effect upon

airflow is dependent upon the amount of

offset

2. Calculate the equivalent ducting

Wowances

using:

~

in. offset) x (14

Ft

per inch)

=

—

Ft

equivalent length.

3. Enter the

dculated

value into

TABE

1 of

this initiation instruction.

4. Ensure that the

toti

equivalent length of

ducting does not exceed the

mtium

recommendation of

lM

feet

(continued

n~p~e)

35

—