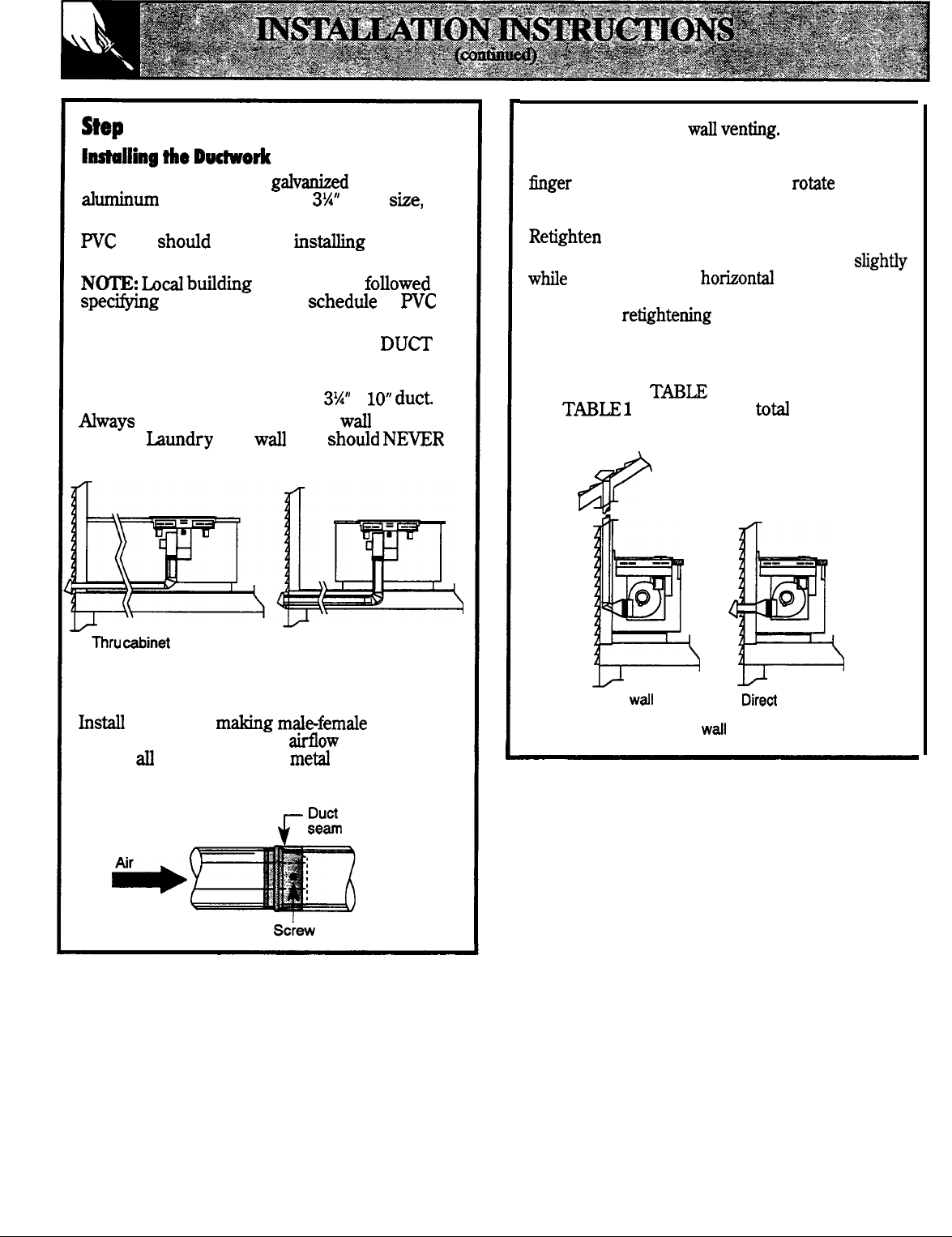

Step

6

Use

minimum

26

gauge

gdvtied

or

24

gauge

d

urninurn

duct in 6“ round or

3%”

x 10”

sk,

or

combination of both.

WC

duct

shodd

be used if

instig

under a

poured concrete slab.

N~:

hd

buflding

code must be

fofiowed

in

spec~g

approved type and

schedde

of

WC

duct used.

5“ round duct maybe used on SHORT

DU~

runs. But, note higher equivalent lengths for

each 5“ dia. piece used. Don’t convert back to

5“ duct after use of 6“ round or

3%”

x

10”

duct

Aways

use an appropriate roof or

wd

cap with

damper.

bundry

type

WW

caps

shodd

NE~R

be used.

pm,~m,,

Thru

~binet

toe space

Between floor joist

Downward venting

hsti

ductwork,

mtig

mdefemde

connections in direction of

tiow

as shown.

Secure

d

joints with sheet

meti

screws and

duct tape to assure airtight seal.

F

Dud tape over

sem

and screw

.

h

Flow

Select

downward or

WW

ventig.

To convert

blower exhaust direction, remove four nuts

inside the plenum which hold blower and wire

tiger

guard. Remove blower and

rotite

so that

exhaust faces downward or rear direction

needed. Replace wire finger guard and nuts.

Retighten

nuts.

Blower exhaust direction can be adjusted

sfightiy

wtie

in its vertical or

hotionti

direction by

loosening four nuts holding blower, rotating

blower and

retightetig

nuts.

Use the shortest and straightest duct run

possible. For satisfactory performance the duct

run should

not exceed 100 feet equivalent

length. Refer to

T~N

1 of equivalent lengths.

Use

T~M

1

to calculate the

toti

equivalent

length of the ductwork.

#

Inside wdl to roof

Dired to outside

Rear

wdl venting

36