10569000246

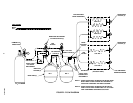

3. Open the CO

2

cylinder shutoff valve slightly to allow the primary CO

2

regulator to fill with gas, then open

the valve fully to back-seat the valve. Back-seating the valve prevents leakage around the valve shaft.

4. Adjust the primary CO

2

regulator by loosening the regulator adjusting screw lock nut, then turn the adjust-

ing screw to the right (clockwise) until the gage reads 50-PSI. Tighten the adjustment screw lock nut after

adjustment has been completed.

5. Adjust beer kegs secondary CO

2

regulators as follows:

The beer kegs secondary CO

2

regulators pressures adjustments require calculations of each beer system

total beer system pressure. The total beer system pressure, required to push beer from the beer keg to the

dispensing faucet, is the result of computing the length of the beer line of a certain size, vertical line lift, and

internal beer keg pressure. The internal beer keg pressure differs from one beer brand to another. Contact

your local Beer Distributor for the proper secondary CO

2

regulators pressure settings. Adjust the secon-

dary CO

2

regulators by loosening the adjusting screws lock nuts, then turn the adjusting screws to the right

(clockwise) until regulators gages register the recommended pressures. Tighten the adjustments screws

lock nuts after adjustments have been completed.

6. Install tappers in the beer kegs.

7. Open shutoff valves located in the CO

2

lines connected between the secondary CO

2

regulators and the

beer kegs tappers.

UNIT OPERATION

8. Dispense beer from the beer faucets until all air is purged from the beer systems.

9. Check beer systems for leaks and repair if evident.

10. Adjust beer faucets for beer flow rate as instructed in SERVICE AND MAINTENANCE section of this

manual.