IntelliCarb Training Manual

Publication Number: TP01071 - 36 - © 2004, IMI Cornelius Inc.

The chart indicates that heavy syrup with 1/2 oz./sec [15mL] flow-rate (per the illustration) can be

sustained over a horizontal distance of 500 ft.

[152M] when 3/8" I.D. [10mm] tubing is used.

Feet: Take

1% of 500 ft. (500 x 1%) = 5. Which then is multiplied by the 22 ft. vertical, (22 x 5) =

110 ft.

Subtract this product from the 500 ft.

(500 - 110) =390. The results indicate a 390 ft. tubing run

(horz./vert.) is possible, while the example only requires a distance of 370 ft.

Meters: Take

3% of 152M (152 x 3%) = 4.56. Which then is multiplied by the 6.7M vertical, (4.56 x

6.7)

= 30.5M.

Subtract this product from the 152

M (152-30.5)=121.5. The results indicate a 121.5M tubing run

(horz./vert.) is possible, while the example only requires a distance of 113M.

NOTE: Had the example above resulted in a value that was equal to, or less than the nec-

essary total tubing run, consider a larger I.D. tubing or installation of a pum

p(s) in series

using a SHURflo Vacuum Regulator.

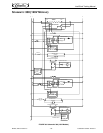

Pumps in Series for Long Distances

Long tubing runs or high vertical lift can be achieved by installing pumps in series. Standard

SHURflo Beverage pumps are not designed to have positive pressure on the inlet side. The

SHURflo Vacuum Regulating Valve

(VRV) allows the pump to receive liquid from a pressurized

source. By positioning a VRV at the inlet of the secondary pump, incoming pressure is

reduced

to zero, permitting syrup to be drawn in under vacuum.

SHURflo can recommend several other methods to meet the requirements for a particular installation,

including Pressurized Inlet Pumps or Accumulators. Contact SHURflo for more information.

Pump Sanitizing / Winterizing

Sanitization of the SHURflo Beverage Gas Pump is required. The frequency of Sanitization is

dependant on the concentrate type and its manufacturer’s requirements.

Factors which also

affect the frequency of this procedure are: temperature, concentrate volatility, facility conditions,

installation and equipment. The sanitizing procedure fulfills a required 10 minute contact time

with a 200 ppm Sodium Hypochlorite solution. Refer to SHURflo Service Bulletin #1025 for the

N.S.F. listed sanitizing procedure for the SHURflo pump

(only). Pumps that are subjected to

freezing

(below 32° F [0°C]) must be purged of fluid to prevent damage. Refer to SHURflo

Service Bulletin #1025 for complete winterizing procedure. Refer to the equipment

manufacturer’s instructions for sanitizing and winterizing procedure for carbonators, dispensers

and tubing.

Pumps that have been winterized and/or out of service for a period of time should be sanitized prior to

being placed back in service.

Never apply pressure to the pump’s liquid inlet. Pressurized tanks may damage internal

components if used to sanitize or purge fluid from the pump

(operating or not).

GAS IN

B-I-B

SECOND

PUMP

VRV

FIRST

PUMP

TO NEXT

VRV/PUMP

OR

DISPENSER

GAS TO NEXT

PUMP