22

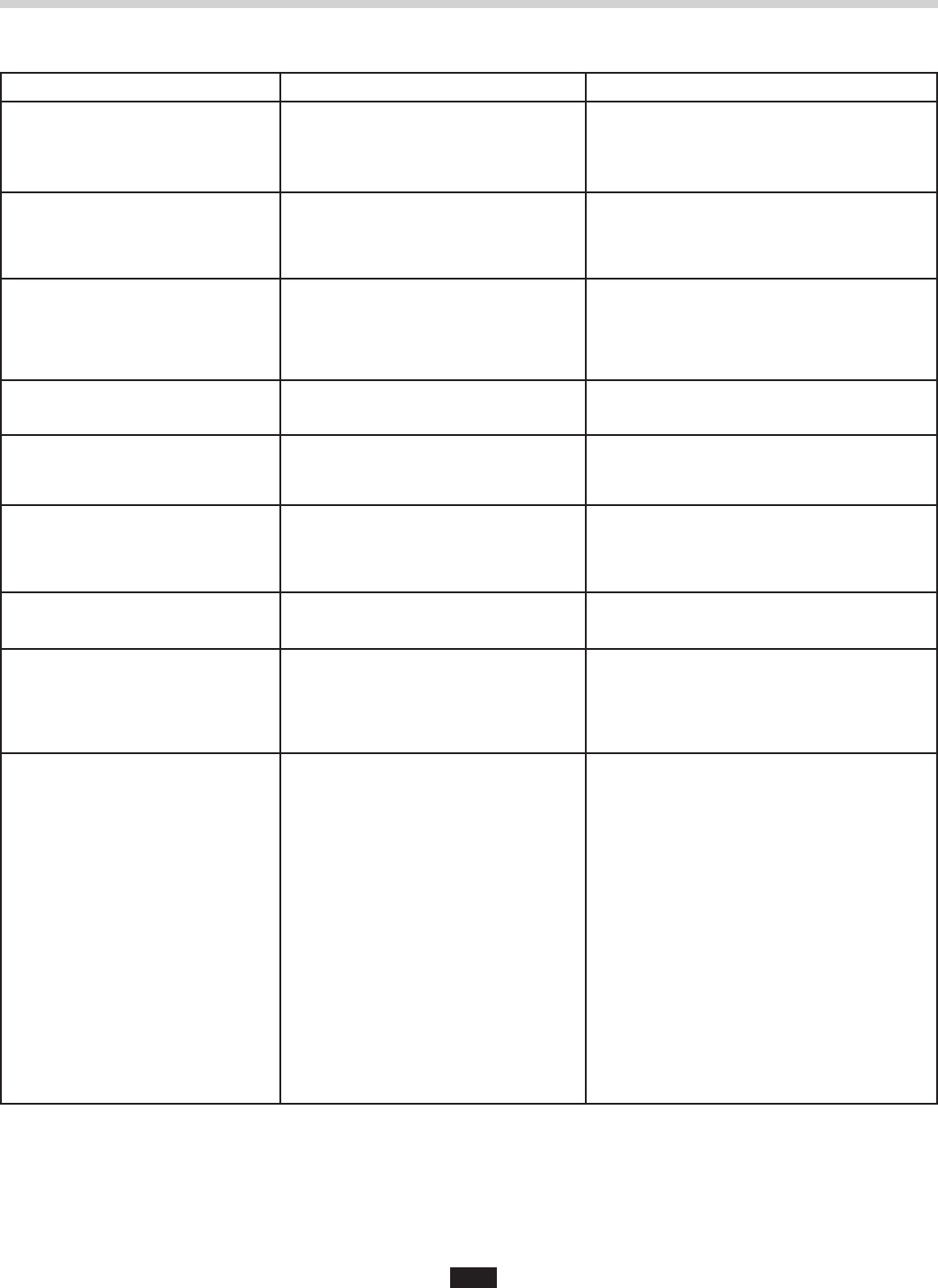

PROBLEM POSSIBLE CAUSE SOLUTION

Auger runs in counterclockwise

(CCW) direction.

• Power to auger motor reversed. • Reverse motor leads to auger motor or

switch L1 and L2 connections on Waste

Xpress terminal block. Auger must run in

clockwise direction.

Unit does not shut off with cover off

of Waste Xpress unit.

• Waste Xpress Interlock not

operating properly.

• Check interlock switch #3 and #95

connections on WX-101A to Waste Xpress.

• Call for service.

Hot water spray is cold. • Incorrectly plumbed.

• No hot water.

• Connect solenoid on Waste Xpress unit to

hot water source.

• Ensure hot water heater/source

is functioning.

Hot water spray does not work. • Incorrectly wired. • Check connections on WX-101A #7 to

WX #18.

Auger reverses direction on

each re-start.

• Waste Xpress unit auger motor

has been wired into disposer

motor circuit.

• Re-wire as shown in instructions.

Waste Xpress unit will not start. • Incorrect wiring.

• Misaligned Interlock switch on chute.

• Safety interlock switch is defective.

• Check wiring.

• Check chute for tight fit.

• Call for service.

Water shuts off when unit shuts off. • Improper dip switch setting

(circuit board).

• Refer to Page 16 to refer to dip switch

setting instructions.

Repetitive "hammering" sound

coming from Waste Xpress unit

while running – no waste exiting

unit at discharge chute.

• Auger has become plugged – system

has either been "batch fed" or auger

drive system has failed. Waste buildup

causing auger to malfunction – not

engaging with auger drive correctly.

• Shut system down and clean unit.

Determine cause of plug.

Waste line clogs between disposer

and Waste Xpress unit.

• System is being "batch fed."

• System is being shut down

prematurely - not being allowed to

properly clear itself of waste.

• Auger and screen not being cleaned

properly. Waste build up has hardened

and created a clog over time.

• Auger is running in wrong rotation.

• Lack of cold water flowing

through system.

• Waste mix has a high fiberous

content (stringy food waste

and/or cardboard).

• Feed waste at a moderate and even rate –

do not attempt to process high volume all

at one time.

• Allow system to run 3-5 minutes before

shutting the sytem down to clear itself.

• Disassemble and clean the Waste Xpress

unit a minimum of once per day.

• Call for service.

• Increase water flow to 5 gpm.

• Card board cannot be processed. Fiberous

food waste should be balanced into the

waste mix with other food waste products

WASTE XPRESS TROUBLESHOOTING

Troubleshooting