59

4

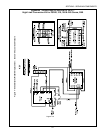

PS360 Series front-mounted thermocouple

inside the machinery compartment

These thermocouples are mounted in a tube that extends

diagonally up and into the plenum chamber. They are se-

cured in place by a set screw located on the mounting

tube, and by a bead of high-temperature silicone around

the end of the shaft.

The new thermocouple will be held in place in the same

manner, except that the silicone should be applied so that

it wraps around the edges of the thermocouples mounting

flange.

NOTE FOR HIGH LIMIT THERMOCOUPLES:

PS310/360 electric ovens have two thermocouples inside

the machinery compartment. One thermocouple is con-

nected to the temperature controller, while the other is

connected to the high limit control module.

The thermocouple supplied in this Kit is incompatible with

the early United Electric Type 54 and Type 55 high limit

control modules used on these ovens. If the oven is

equipped with one of these control modules, it will be

necessary to upgrade the control unit to the current

Watlow model (shown in Figure 6) before the thermo-

couple can be replaced. Service Kit 39733 includes all

parts and instructions needed for the conversion. Refer

to Service Bulletin MM-168 (5/7/99) for details.

1. Remove the silicone seal around the end of the thermo-

couple. Loosen the set screw.

2. Pull the thermocouple out of its mounting tube. Care-

fully thread the wiring out of the oven and discard the

thermocouple.

3. Check that the silicone has been removed completely

from the end of the mounting tube. Any remaining sili-

cone can interfere with the correct placement of the

new thermocouple.

4. Insert the new thermocouple until its flange is seated

on the end of the mounting tube. See Figure 5.

5. Tighten the set screw until the thermocouple is secure

inside the tube. AVOID OVERTIGHTENING THE SET

SCREW TO PREVENT DAMAGE TO THE THERMO-

COUPLE.

6. Use high-temperature silicone to seal the flange to the

mounting tube, as shown in Figure 5. Check that all

holes and spaces are filled by the silicone. This not

only helps to hold the thermocouple in place, but pre-

vents heat from entering the machinery compartment.

7. Route the wiring for the new thermocouple through the

hole in the side of the electrical control box by using

the existing wiring bundle. Check that the leads are

clear of the ignition cable and all components.

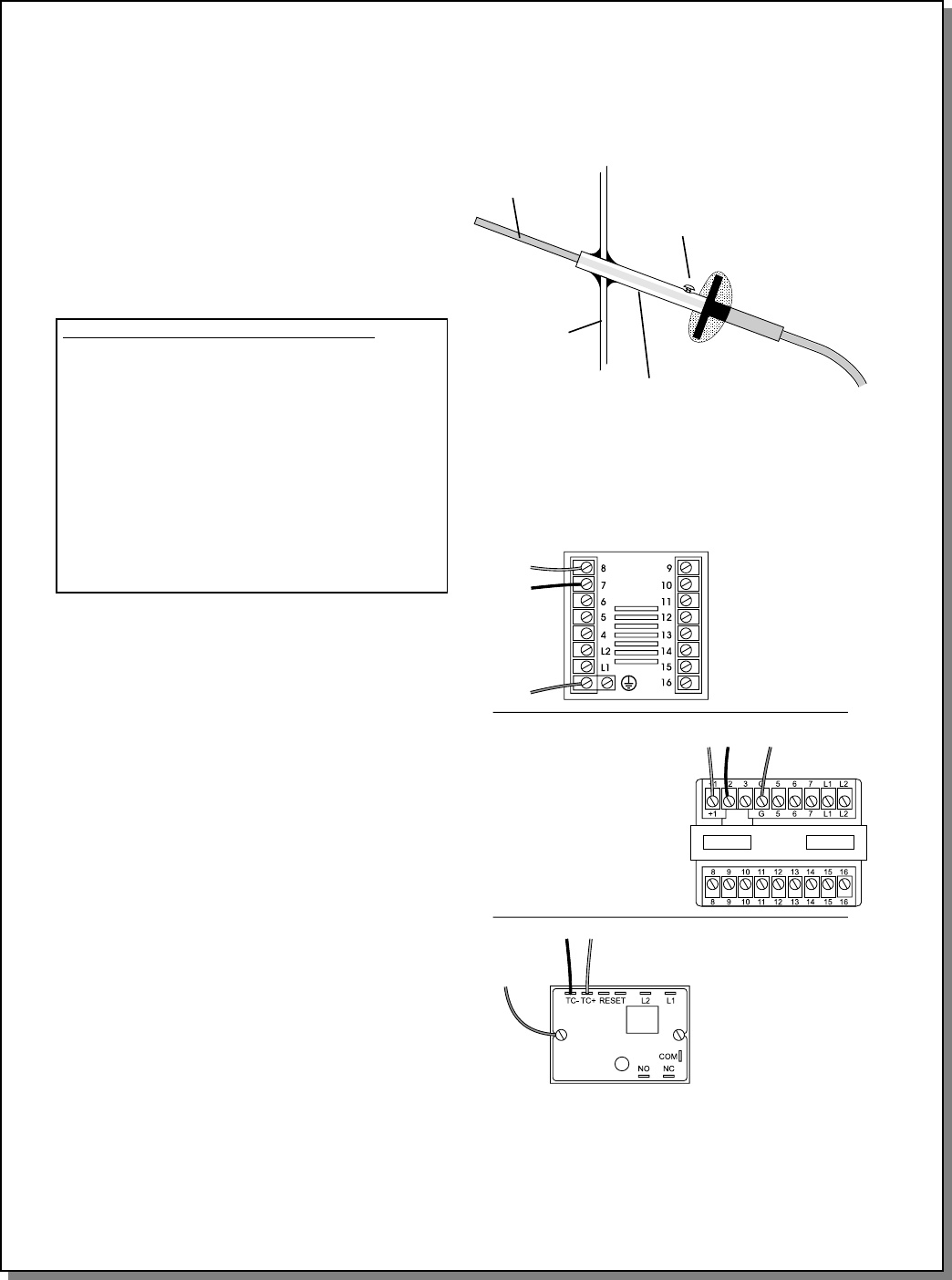

8. Connect the leads as shown in Figure 6.

Figure 5

Thermocouple Installation - PS360 Series

Machinery Compartment

Thermocouple

Mounting

tube

Set

screw

High-temperature

silicone wraps around

thermocouple flange

and onto mounting

tube

Plenum

wall

Figure 6

Thermocouple Wiring - PS360 Series

Digital

Temperature

Controller

Analog

Temperature

Controller

Red

White

Shielded

ground lead

RedWhite

Shielded

ground lead

High Limit

Control

Module

Shielded

ground lead

Red White

Appendix - Instructions for Service Kits 33984 and 33985 -

Oven Thermocouple Kit, 11/01

SECTION 3 - SERVICING COMPONENTS