92

SECTION 3 - SERVICING COMPONENTS

C. Component Identification

1. Burner type

Middleby ovens are equipped with one of two main burner

designs. Details of these burners are provided below.

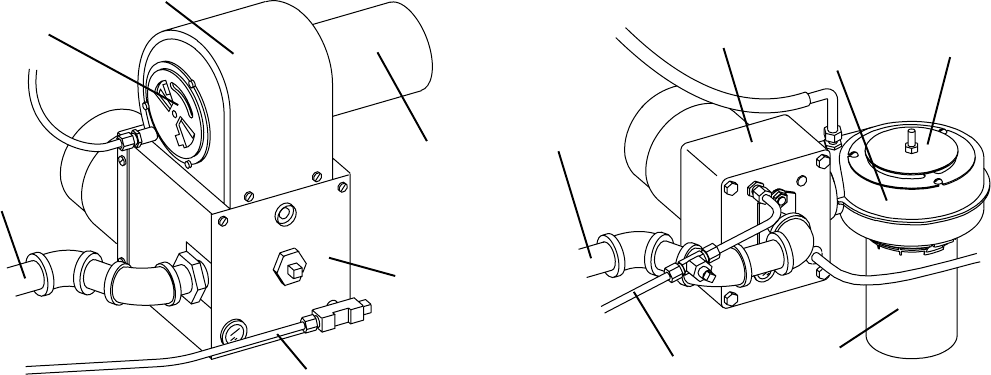

1. Midco burner - see Figure 61. This burner was

used on PS360WB70 and PS360EWB ovens only.

Late-production PS360EWB and PS360WB70 ov-

ens used the Wayne burner shown in Figure 62. In

addition, many PS360EWB ovens were retrofitted

during 1998 to use the Wayne burner.

Servicing the Midco burner is beyond the scope of

this manual. However, note that most gas train

components EXCEPT FOR THE BURNER ITSELF

are identical to the components used with the

Wayne burner. If necessary, contact Middleby Tech-

nical Service for assistance.

2. Wayne burner - see Figure 62. Wayne burners are

used on all Middleby oven models except early-

production PS360WB70 and PS360EWB models.

The Wayne burner configuration varies slightly be-

tween oven models and so may be slightly differ-

ent from that shown in Figure 62. Refer to the

drawings in Part Number Reference - Burner Com-

ponents (pages 88-90) for illustrations of the burner

configuration used on each oven model. Common

variants include:

Flexible air tube between the burner blower and

plenum. Used on all PS555/570 series ovens.

120V burner blower motor. Used on PS200-

series (through 3/02), PS310, PS314, PS360,

PS360WB and PS570S ovens.

208/240V line voltage blower motor. Used on

PS200-series (4/02 or later), PS360WB70,

PS360EWB, PS555, and PS570G ovens.

Figure 61 - Midco burner

Figure 62 - Wayne burner

PS360EWB shown. For different oven models, refer

to the drawings on pages 88-90.

Burner

blower

motor

Air

shutter

Pilot line

Plenum

Main gas

line

Air shutter

Burner blower

Burner

blower

Burner

blower

motor

Pilot line

Plenum

Main gas

line

1. Solenoid valve vs. Modulating valve

Middleby ovens use one of the following systems for

gas flow regulation:

On-Off gas flow regulation. These ovens are

equipped with a high flame solenoid valve. The

solenoid valve can only be positioned fully open

(100% gas flow) or fully closed (0% gas flow) as

necessary to maintain the set point. A bypass line

supplies gas to maintain the flame when the valve

is closed. On/off gas systems have a temperature

swing of several degrees on either side of the set

point.

On-Off gas flow regulation is used on the following

Middleby oven models:

- PS360WB

- PS360WB70

- PS570S

(through 8/00)

Additional information on the solenoid valve is pro-

vided in Solenoid Valve on Page 96.

Modulated gas regulation. These ovens are

equipped with a modulating gas valve. The modu-

lating valve can open or close at any setting from 0-

100% gas flow in response to the need for heat to

maintain the set point. Because of this flexibility,

the temperature swing is eliminated.

The modulated gas system is used on the following

Middleby oven models:

- PS200-series

(through 3/02)

- PS310

- PS314

- PS360

- PS200-series

(4/02 or later)

- PS360EWB

- PS555

- PS570S

(9/00 or later)

- PS570G

Additional information on the modulating valve is

provided in Modulating Valve on Page 97.