79

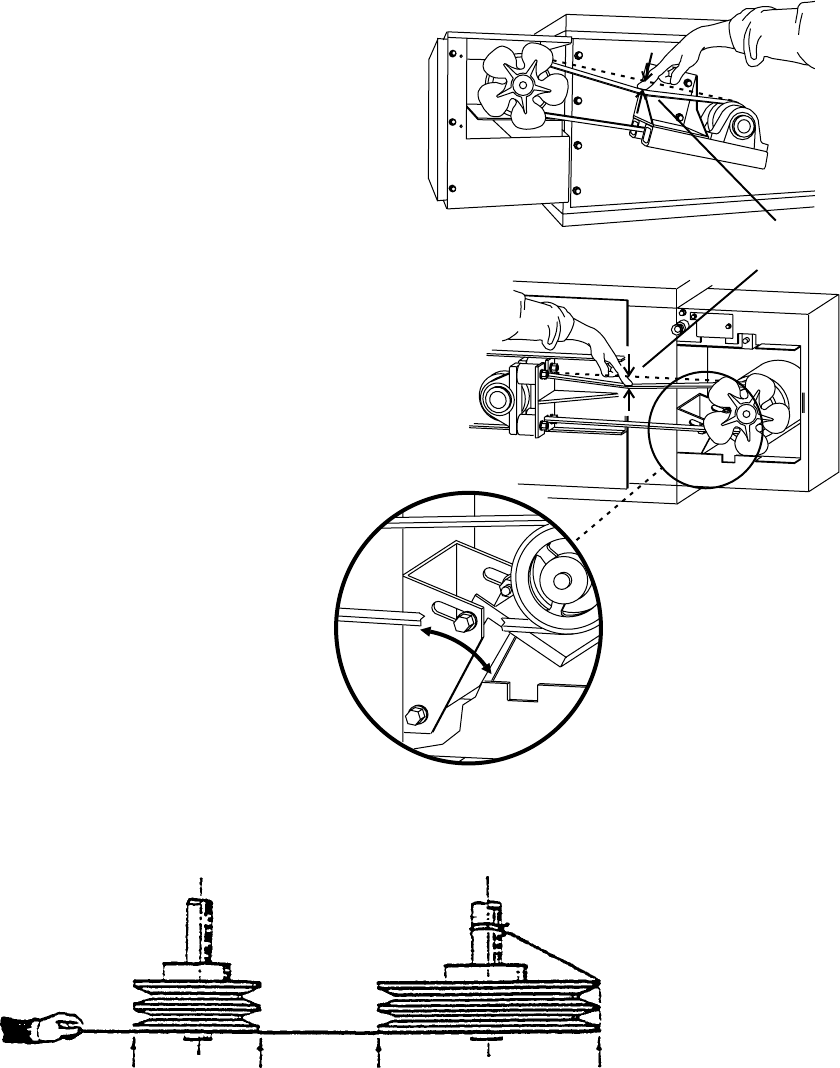

4. Blower belt tension

NOTE: Middleby recommends checking the blower

belt condition and tension every three months.

Check the blower belt for at least 1" / 25mm deflection

at the center, and for cracking or excessive wear.

Overtightening the belt will cause premature bearing

failure and possible vibrations. See Figure 47.

If necessary, adjust the tension of the belt by loosening

the two motor mounting bolts as shown in Figure 47.

Reposition the motor as neccessary until the correct

deflection is reached, then tighten the bolts.

Figure 47

Blower belt tension and

repositioning the blower motor

Loosen bolts to

reposition motor

and adjust belt

tension

1 (25mm)

vertical

deflection

PS570,

PS570S

PS570G,

PS555

5. Bearing replacement and alignment

Whenever service to the blower shaft or replacement of

the bearings is required, the shaft will need to be aligned.

NOTE: Apply anti-seize compound (MM P/N 17110-

0017) to all bolts before installing back wall assembly

to oven.

First, reassemble the back wall components, but DO

NOT TIGHTEN THE HEX BOLTS that hold the bearings

to their mounting brackets. Leaving the bearings loose

allows the pulleys to be aligned.

Next, check the alignment of the pulleys using a cord

as shown in Figure 48. Reposition the bearings as

required to align the blower shaft, then tighten the hex

bolts to hold the shaft in place.

Replace the belts and rear shrouds after the pulleys

are properly aligned.

Figure 48 - Four-point alignment test for correct pulley alignment

Cord tied to shaft

Cord must touch sheaves at four points indicated by arrows

SECTION 3 - SERVICING COMPONENTS