7

SECTION 2

AIR FLOW AND HEAT TRANSFER

I. TYPES OF HEAT TRANSFER

Heat constantly moves from a warm object to a cold ob-

ject. Heat moves in three different ways: thorough con-

duction, through radiation, and through convection.

Middleby Marshall conveyor ovens use all three of these

paths to cook the product.

Conduction - Heat is transferred through surface con-

tact (such as pizza dough in contact with a pan).

Radiation - Heat is transferred from light-colored ob-

jects to dark-colored objects. The darker the color of

an object, the greater the amount of heat that it ab-

sorbs. The lighter the color of an object, the greater

the amount of heat that it reflects. Middleby ovens use

light-colored interiors (aluminized or stainless steel,

depending on the oven model) to reflect as much heat

as possible to the product.

Convection - Heated air will transfer heat to objects

with which it comes into contact. Unless the air flow is

controlled, hot air will rise and be replaced by cooler

air. Middleby Marshall ovens use blowers (one or two

large fans, depending on the oven model) to force air

through adjustable air fingers onto the product.

The intensity of the heat at the point at which it is sensed is

called temperature. The difference in temperature between

the food product and the heat source - that is, the pan,

oven interior, or heated air, as described above - determines

the speed at which the heat flows. The greater the differ-

ence in temperature, the faster the heat flows to the prod-

uct.

In Middleby Marshall conveyor ovens, the heat transfer from

conduction is greatly dependent on the customers product

and cooking surface (pans, etc.). Likewise, the heat trans-

fer from radiation is effectively constant, because the color

of the oven interior cannot be changed. For these reasons,

the best way to optimize heat transfer is by regulating the

convection air. This can be done in two ways:

Adjusting the

blowers and blower speed to change the

quantity and velocity of air delivered onto the product.

Adjusting the air finger configuration to change the pat-

tern in which the vertical columns of air are delivered to

the product.

II. BLOWERS AND BLOWER SPEED

A. PS200-series ovens

PS200-series ovens have a single blower motor mounted

inside the machinery compartment, with a pulley on

the end of the motor shaft. A belt connects this pulley

to another on the shaft of the blower fan. The air veloc-

ity can be changed by using a larger or smaller pulley

on the motor shaft, and changing the length of the belt

to match the new pulley. See Figure 1.

However, note that there are only two approved belt/

pulley combinations for PS200-series ovens; one for

60Hz ovens, and one for 50Hz ovens. Field modifica-

tions to these approved combinations are not permit-

ted unless under the specific directions of the Middleby

Technical Service Department. Any changes to con-

vection air delivery MUST be made using the air fin-

gers.

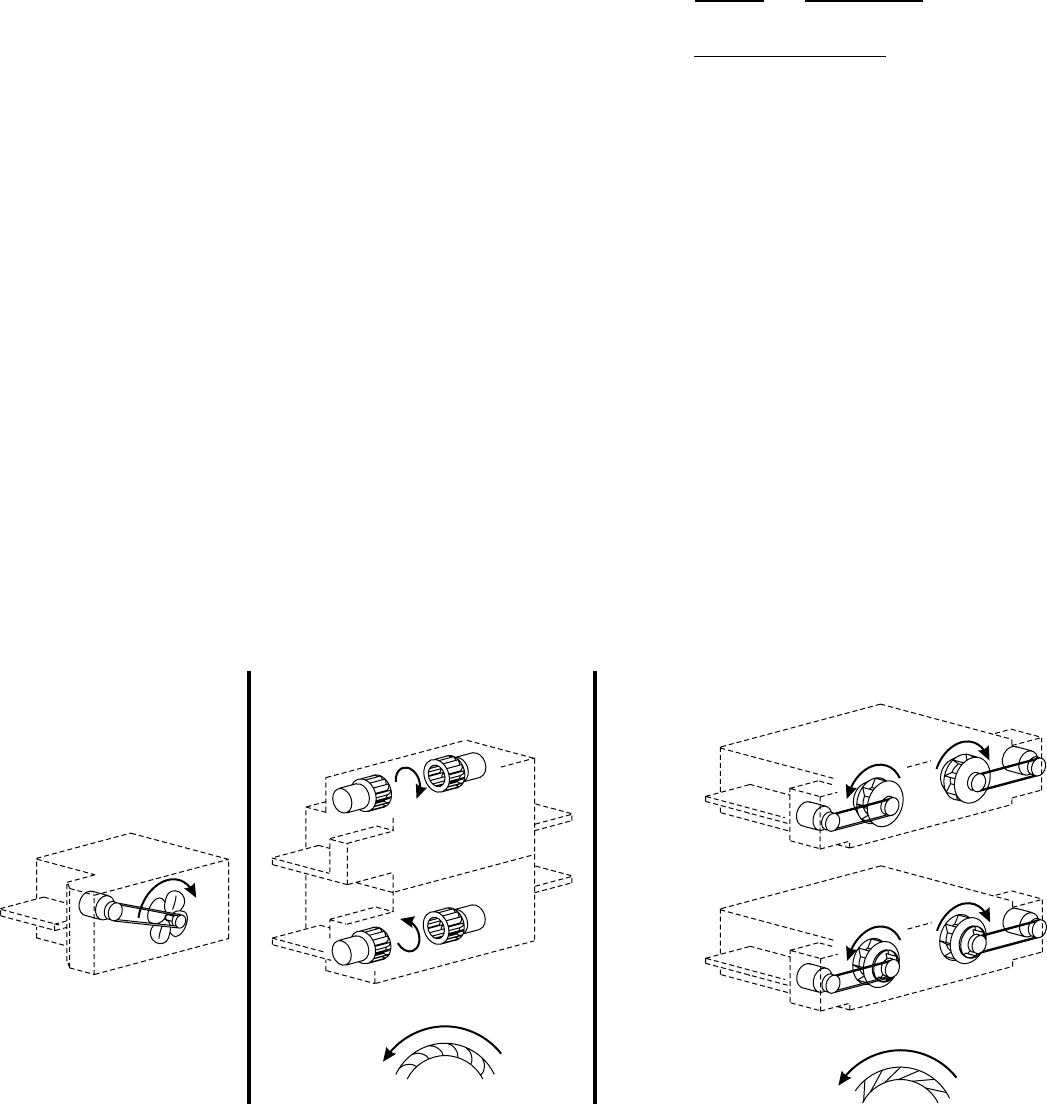

SECTION 2 - AIR FLOW AND HEAT TRANSFER

Figure 1

Blowers, belts and pulleys

PS200-series

PS360-series PS555/570-series

Current

(PS570S,

PS570G, all

PS555)

Early

(PS570)

Blower Wheel

Orientation

Blower

Wheel

Orientation