15

5. If it is necessary to add or remove conveyor links to

achieve the correct tension, OR if it is necessary to

reverse the conveyor belt for correct orientation, the belt

will need to be removed from the conveyor frame. If this

is necessary, perform the following procedure:

Remove the conveyor assembly from the oven and

place it flat on the floor.

Remove the master links using long-nose pliers.

Then, roll up the belt along the length of the

conveyor frame.

Add or remove belt links as necessary to achieve

the correct belt tension.

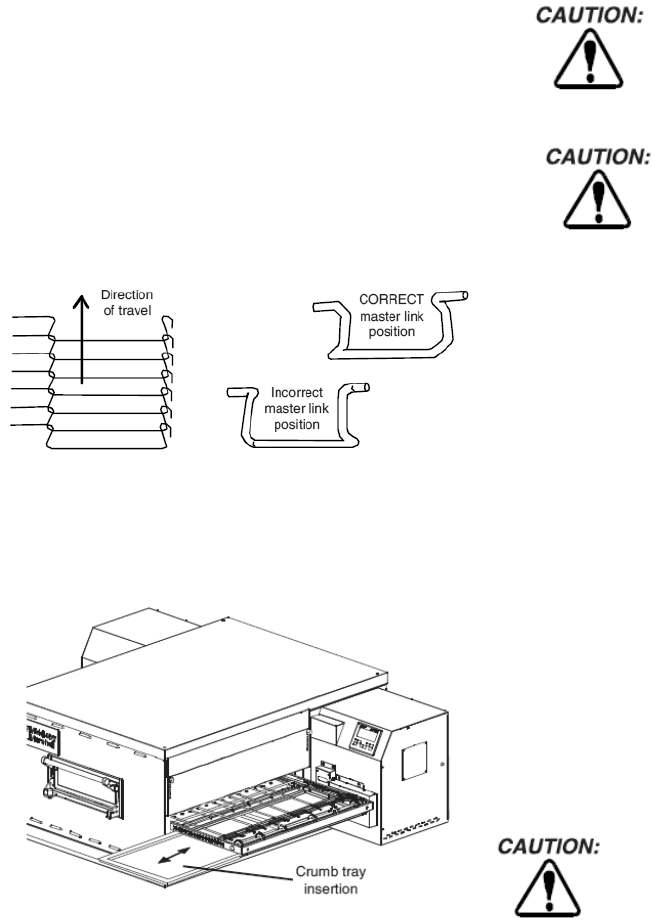

Replace the belt on the conveyor frame. Check that

the conveyor belt links are oriented as shown in

Figure 2-15, and that the smooth side of the

conveyor belt faces UP.

Connect the inside master links. Check that the

links are oriented as shown in Figure 2-15.

Connect the outside master links. Note that the

outside master links each have an open hook on

one side. This hook aligns with the hooks along the

sides of the other conveyor links. See Figure 2-15.

Replace the conveyor into the oven.

Figure 2-15. Conveyor and Master Link orientation

E. Final Assembly

1. Install the crumb trays underneath the conveyor as

shown in Figure 2-16.

Figure 2-16. Crumb Trays

CONVEYOR BELT REVERSAL

Conveyor belt reversal consists of three steps:

1. Physically reversing the conveyor belt

2. Resetting the conveyor travel direction through the User

Interface.

3. Switching the photo sensor.

REVERSING THE CONVEYOR BELT

Remove the conveyor from the oven and find the master link

location. Remove master links and remove the belt from the

conveyor frame. Reassemble the belt back onto the frame

(in the reverse direction) and reinstall the master links.

Replace the conveyor assembly in the oven.

RESETTING DIRECTION

See OVEN CONFIGURATION MENU in the PS360G TECH

GUIDE. Direction is changed through the User Interface with

no wiring changes necessary.

Shock hazard in compartments electrical

filters are electrically alive.

SWITCHING PHOTO SENSOR

Disconnect power before switching Photo

Eye.

Remove the three screws securing the access door to the

unit. Open the access door and disconnect the connector

fitting to the photo eye assembly. Remove the two screws

securing the photo eye assembly to the control box. Remove

the four nuts securing the photo eye to the housing. Rotate

the photo eye 180 degrees and affix the photo eye with the

four nuts. On the opposite control box, remove the two

screws holding the cover where the photo eye assembly will

be positioned. Secure the photo eye assembly in position

with the two screws. Place the photo eye cover on the

opposite control box, where the photo eye assembly was

removed, and secure the two screws. Secure the access

door with the three screws. Remove the three screws

securing the access door on the opposite side. Open the

access door, where the photo eye is now positioned, and

connect the photo eye connector fitting. Secure the access

door with the three screws. Apply power to the unit. Adjust

the photo eye height by loosening the two screws securing

the photo eye assembly and sliding the photo eye assembly

either up or down, such that the beam is approximately 1/4

inch above the belt.

Note: This is MUCH easier in reduced light.

Replace all covers.

VI. ELECTRICAL SUPPLY

Authorized installation personnel normally

accomplish the connections for the ventilation

system, electric supply, and gas supply, as

arranged by the customer. Following these

connections, the factory-authorized installer

can perform the initial startup of the oven.

NOTE: The electric supply installation must satisfy the

requirements of the appropriate statutory authority such

as the National Electrical Code, CSA C22.2; the Australian

Code AG601; or other applicable regulations.

NOTE: The electric supply connection must meet all national

and local electrical code requirements.