17

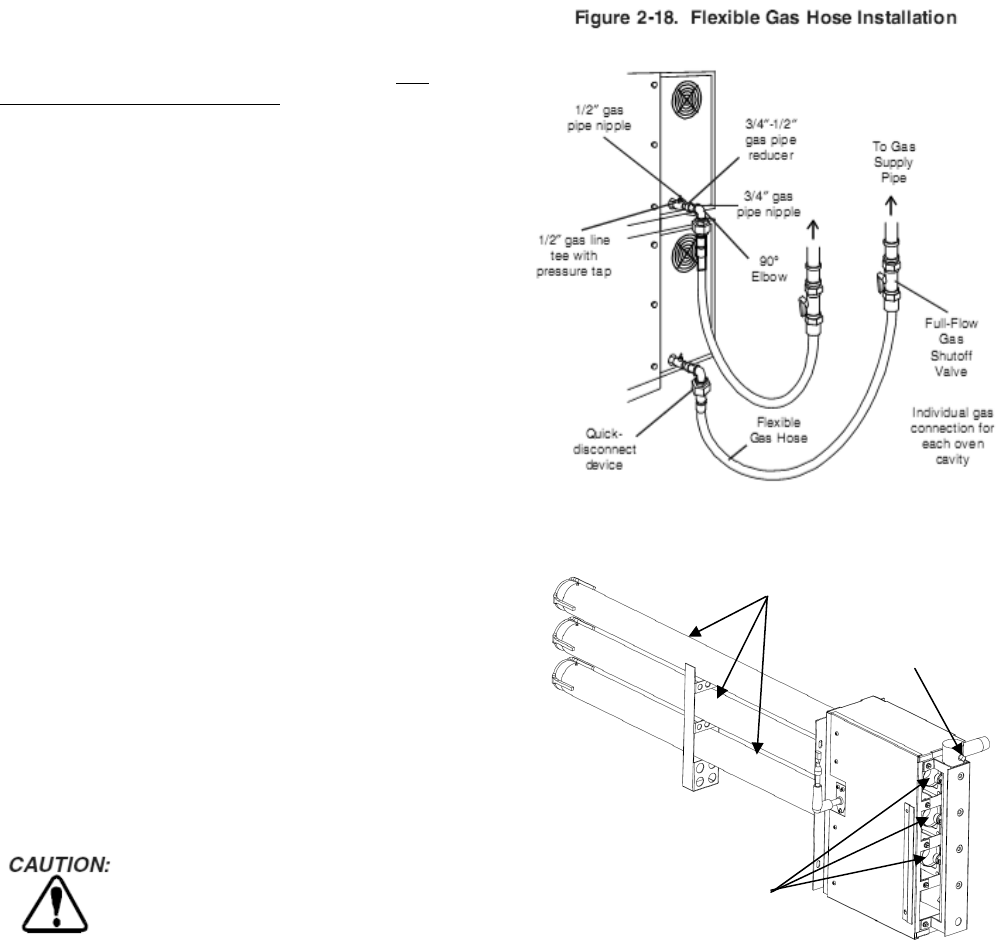

B. Connection

Check the oven’s gas supply requirements before making

the gas utility connections. Gas supply requirements are

listed on the oven’s serial plate and in Table 1-4. Gas

Orifice and Pressure Specifications (in Section 1,

Description).

Check the serial plate to determine the type of gas (Propane

or Natural) to be used with the oven.

Refer to the instructions in the gas hose package (included

in the Installation Kit) before connecting the gas line. One

gas line connection method is shown in Figure 2-18;

however, compliance with the applicable standards and

regulations is mandatory.

Inlet, regulated, and pilot gas pressure readings can be

taken using a digital tube manometer at the tap location

shown in Figure 2-19. Figure 2-19 shows the burner

assembly and Figure 2-21 shows the gas valve.

NOTE: The installation must conform with local codes or in

the absence of local codes, to the National Fuel

Gas Code, ANSI Z223.1-latest edition.

Certain safety code requirements exist for the installation of

gas ovens; refer to the beginning of Section 2 for a list of the

installation standards. In addition, because the oven is

equipped with casters, the gas line connection shall be made

with a connector that complies with the Standard for

Connectors for Movable Gas Appliances, ANSI Z21.69 (in

U.S.A.), as well as a quick-disconnect device that complies

with the Standard for Quick-Disconnect Devices for Use With

Gas Fuel, ANSI Z21.41 (in U.S.A.).

C. Gas Conversion

Where permitted by local and national codes, it is possible to

convert ovens from natural gas to propane or from propane

to natural gas. Use the appropriate Middleby Gas

Conversion Kit for the specific oven model.

The terms of the oven’s warranty require all

startups, conversions and service work to be

performed by a Middleby Authorized Service

Agent.

D. PS360G Propane Conversion

Two items must be changed to change the oven to operate

on LP:

1. Replace main orifices.

2. Adjust main gas regulator per instructions below.

Disconnect the manifold union closest to the main burner,

and remove the manifold assembly (four screws). Slide out

the manifold assembly (leaving the ignition and sense wires

connected). Replace the main orifices.

Replace the main orifices on the manifold assemblies with

the LP units, and replace the manifold assembly. Reconnect

the union.

E. Adjusting the Maximum Pressure Setting

1. Disconnect pressure feedback connection (if applicable).

2. Connect a suitable pressure gauge to pipe line or to outlet

pressure tap of gas control concerned, to measure burner

pressure (measuring point must be as near to burner as

possible).

Figure 2-19. Gas Burner Assembly

3. Make sure that the appliance is in operation and the

Moduplus

® coil is energized with maximum current.

4. If maximum rate pressure needs adjustment, use an 8 mm

wrench to turn adjustment screw for maximum pressure

setting (clockwise to increase or counter-clockwise to

decrease pressure), until the desired maximum outlet

pressure is obtained.

5. Disconnect electrical connection of the Moduplus

®.

6. Check minimum pressure setting and readjust if

necessary. (See Adjusting Minimum Pressure Setting for

proper adjusting procedure.)

7. Reconnect pressure feedback connection (if applicable).

8. If minimum and maximum pressures are set, wire the

Moduplus

® in circuit.

9. Close pressure tap screw.

FLAME TUBES

MANIFOLD

PRESSURE TAP

GAS BURNERS