16

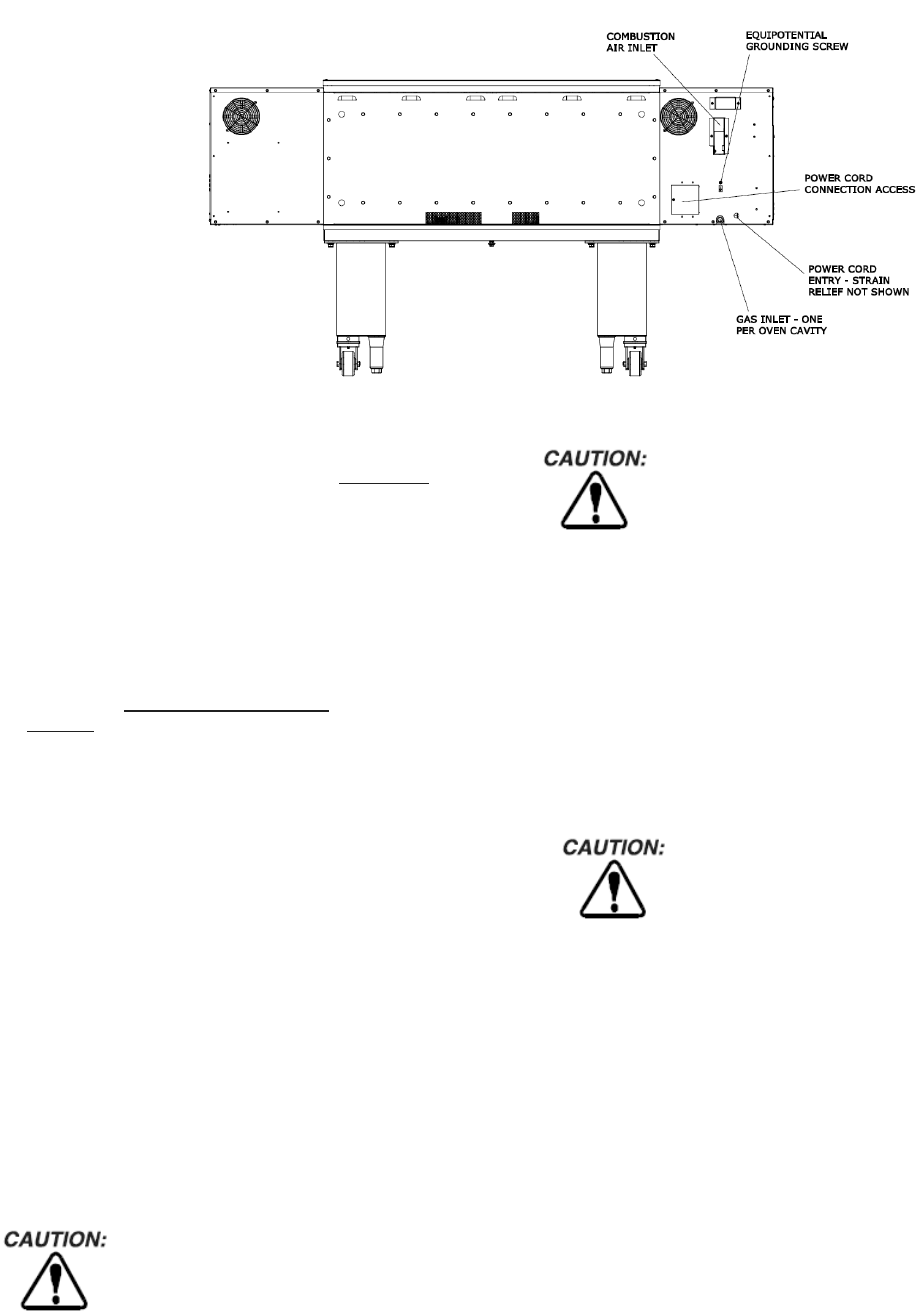

Figure 2-17. Utility Connection Locations

Check the oven serial plate before making any electric

supply connections. Electric supply connections must agree

with data on the oven serial plate. The location of the serial

plate is shown in Figure 1-1 (in Section 1, Description

).

A fused disconnect switch or a main circuit breaker

(customer furnished) MUST be installed in the electric supply

line for each oven cavity. It is recommended that the

switch/circuit breaker have Lockout/Tagout capability.

The supply conductors must be of the size and material

(copper) recommended. Refer to the wiring diagram inside

the machinery compartment of the oven. Electrical

specifications are also listed on the oven’s serial plate and in

Table 1-3, Electrical Specifications

(in Section 1,

Description

).

The oven requires a ground connection to the oven ground

screw. For gas ovens, the screw is located in the electrical

junction box (see Figure 2-14). If necessary, have the

electrician supply the ground wire. Do NOT use the wiring

conduit or other piping for ground connections.

Incoming electrical power lines are fed through the strain-

relief fitting, shown in Figure 2-14. The electrical supply

connections are made inside the electrical junction box. The

power lines then connect to the oven circuits through safety

switches located inside the machinery compartment and

each blower motor compartment. These switches interrupt

electrical power to the oven when the Machinery

Compartment Access Panel is opened, OR when the rear

panel is removed.

Connection

Refer to the wiring diagram inside the machinery

compartment of the oven to determine the correct

connections for the electrical supply lines. Connect the

supply as indicated on the wiring diagram.

The terms of the oven’s warranty require all

start-ups, conversions and service work to be

performed by a Middleby Marshall Authorized

Service Agent.

VII. GAS SUPPLY

DURING PRESSURE TESTING NOTE

ONE OF THE FOLLOWING:

1. The oven and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressure in

excess of ½ psi (3.45 kPa).

2. The oven must be isolated from the gas supply piping

system by closing its individual manual shutoff during

any pressure testing of the gas supply piping system at

test pressure equal to or less than ½ psi (3.45 kPa).

3. If incoming pressure is over 14” W.C. (35 mbar), a

separate regulator MUST be installed in the line

BEFORE the individual shutoff valve for the oven.

To prevent damage to the control valve

regulator during initial turn-on of gas, it is

very important to open the manual shutoff

valve very slowly.

After the initial gas turn-on, the manual

shutoff valve must remain open except

during pressure testing as outlined in the

above steps or when necessary during

service maintenance.

A. Gas Utility Rough-In Recommendations

The following system specifications are STRONGLY

RECOMMENDED. Deviating from these recommendations

may affect the baking performance of the oven.

Gas Meter

One or two cavities: 750 CFH meter

Three oven cavities: 1,200 CFH meter

Gas Line

DEDICATED GAS LINE from the gas meter to

the oven

2” (50.8mm) pipe for Natural gas

2” (50.8mm) pipe for Propane

Maximum length: 2.002 (61m). Each 90° elbow

equals 7’ (2.13m) of pipe.