Gravimetric Batch Blenders w/Mitsubishi Control Chapter 2: Functional Description 18

Each of the diamond gate air cylinders is actuated by a solenoid valve, which are controlled

by the blender.

When the solenoid valve is energized, it opens the metering valve cylinder. When the

solenoid valve is de-energized, it closes the metering valve cylinder.

If the power is interrupted to the blender, the metering valves will return to the closed

position, to prevent material from over-filling the weigh hopper/mix chamber.

Note: If the blender is in metering mode with one of the slide gates open, do not open

the front door of the blender!

Note: The safety switch shuts off the air supply to the blender. An open feeder slide

gate stays open, and an overflow of the weigh hopper can occur!

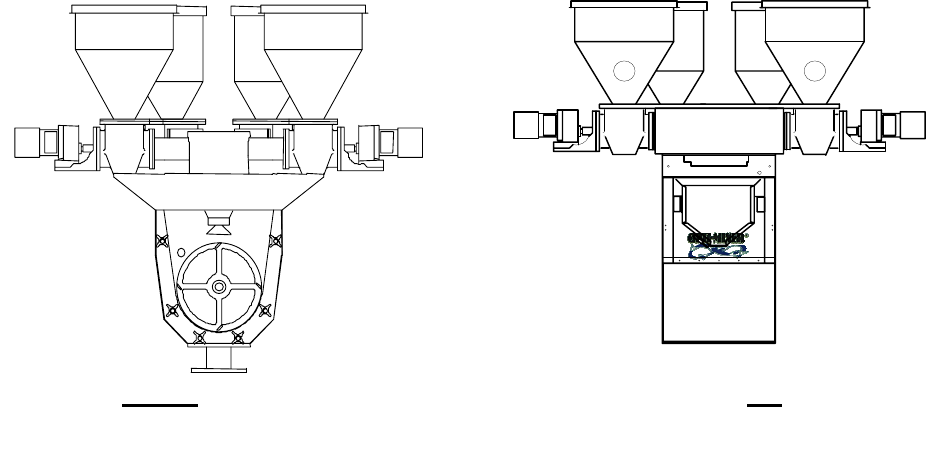

Auger Metering Assemblies

Auger blenders are equipped with auger metering units, including the following components:

• Cast aluminum feeder bodies

• Cast aluminum motor mounts

• Heavy-duty AC gear motors (Optional DC drives are available)

• Drain spouts with slide gate shut-off

• Machined steel auger

• Cast aluminum auger housing

• Spun aluminum material supply hoppers

• Cover with cut-out for vacuum receivers

Figure 5: Auger Blenders available with a Choice of Mixers

Standard “HC” mixer Optional Opti-Mixer®

Multiple regrinds and Pellets and one

more difficult materials free-flowing regrind