Gravimetric Batch Blenders w/Mitsubishi Control Chapter 3: Installation 30

Mezzanine Mount

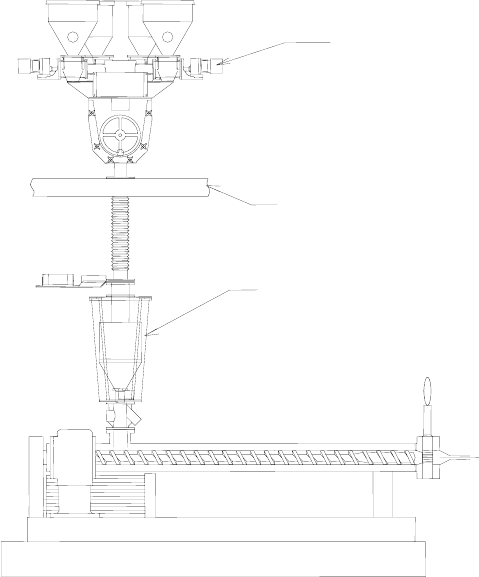

In a mezzanine mount application, review the following items before installation begins.

First, verify the Slide Gate/Auger mounting locations match the mezzanine supports. Verify

that the mezzanine is capable of supporting the blender with a full load of material and

vacuum loading equipment installed.

Note: While in operation, the Slide Gate/Auger blender applies horizontal and

vertical pressures to the mounting flange. If there is a question as to the

mechanical stability of a mounting flange, contact the manufacturer’s

mechanical engineering department.

Ensure that the gravity feed tube is installed in a vertical position, so that the materials will

gravity flow to the extruder hopper. Use aluminum tubing or smooth wall flex hose.

Figure 16: Mezzanine Mounted Batch Blender

GRAVIMETRIC BATCH BLENDER

MEZZANINE (SUPPLIED BY

CUSTOMER)

EXTRUSION CONTROL WITH

RE-LOAD VALVE

(PURCHASED SEPARATELY)

If possible, use rigid tubing. Some flex hose will tend to sag and generate static that could

cause de-mixing between the blender and the extruder.

Make sure that adequate space is around the blender (36” recommended) to allow proper

cleaning, servicing, etc.