Gravimetric Batch Blenders w/Mitsubishi Control Chapter 2: Functional Description 26

Fail Safe Operation

If a safety device or circuit should fail, the design must be such that the failure causes a

“Safe” condition. As an example, a safety switch must be a normally open switch. The switch

must be held closed with the device it is to protect. If the switch fails, it will go to the open

condition, tripping out the safety circuit.

At no time should the safety device fail and allow the operation to continue. For

example, if a safety switch is guarding a motor, and the safety switch fails, the motor should

not be able to run.

Safety Device Lock-Outs

Some safety devices disconnect electrical energy from a circuit. The safety devices that are

used on the Slide Gate/Auger Blenders are primarily concerned with pneumatic and electrical

power disconnection and the disabling of moving parts that may need to be accessed during

the normal operation of the machine.

Some of the safety devices utilize a manual activator. This is the method of initiating the

safety lock out. This may be in the form of a plug, lever or a handle. Within this lockable

handle, there may be a location for a padlock. Personnel servicing the equipment should

place a padlock in the lockout handle.

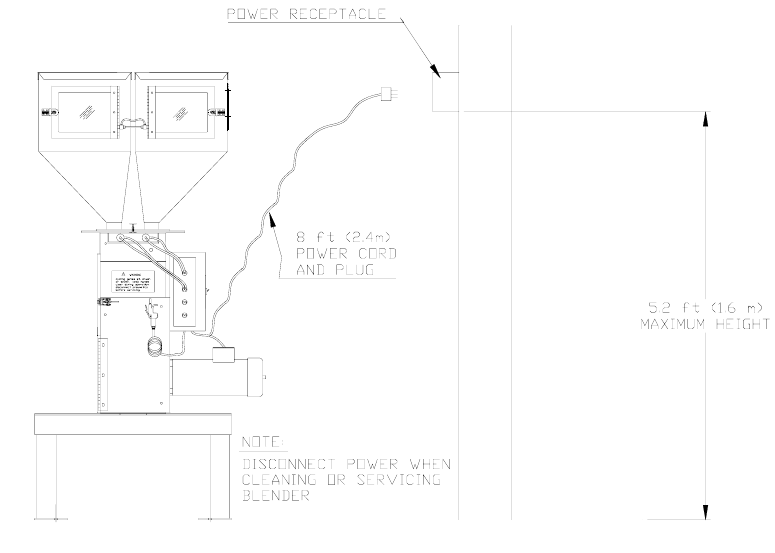

In addition to the safety devices listed above, these blenders are equipped with a line cord

plug (Shown in figures 11 and 12). This allows the operator or maintenance personnel to

unplug the unit from its power source and tag it out. The plug can then be tagged with any

number of approved electrical lockout tags available at most electrical supply stores.

Figure 12: Electrical Disconnect Plug