55

English

10 - INACTIVITY

If the automatic vending machine remains

inactive for a long time it is necessary to take

certain preventive measures:

- with the machine on, start the automatic

emptying process of both the hydraulic circuit

and the boiler (see PROGRAMMING AND

MAINTENANCE MENU in section 8).

- once it is over, disconnect the machine from

the power and hydraulic supply

- disassemble the closing panel on the back

of the machine.

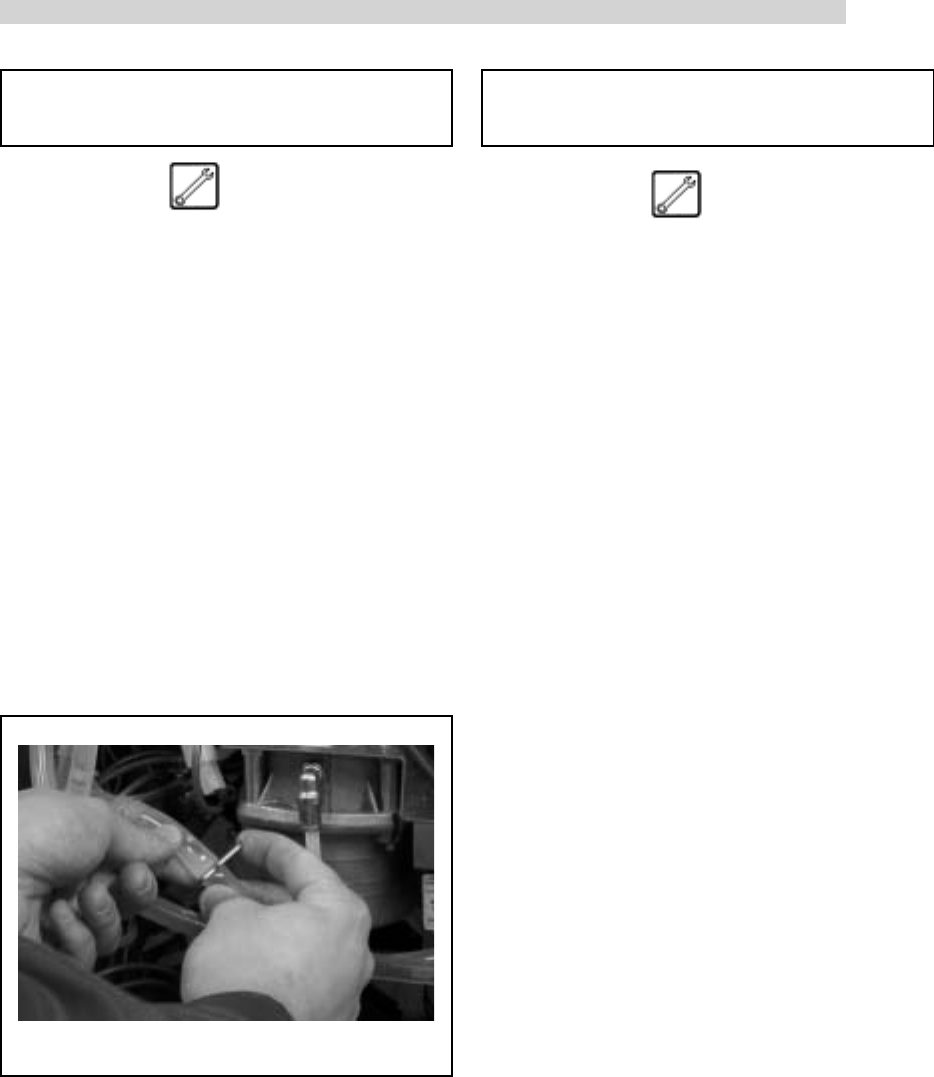

- complete the emptying of the tank with float

by removing the hose clamp located on the

air-break device drain hose

- once the emptying is over, refit the hose

clamp (fig.64)

11 - DISMANTLING

Empty the products and water as described in

the previous section. For dismantling, it is

advisable to disassemble the machine parts

according to their composition - plastic, metal

etc. Afterwards, deliver the divided parts to the

specialised companies. If a refrigerating unit is

present, give it without disassembling it to

companies authorized for the disposal of this

particular part.

- assemble the closing panel on the back of

the machine.

- unload all products from the containers

- wash all the components that are in contact

with foodstuff as previously described

- empty the trays from dry and liquid dumps,

then clean them accurately

- clean all vending machine internal and

external surfaces with a cloth

- protect the outside of the machine with plastic

film or a bag

- store in dry, sheltered environments at a

temperature not lower than 1°C

fig.64