IV. b - FREEZERS:

During normal operation, a freezer continuously cir-

culates below freezing cabinet air through the coil.

The coil requires a periodic defrosting for proper op-

eration. This is accomplished by an automatic, time

activated, temperature/time terminated, defrost pro-

gram. The controller is preset at the factory for six

equally spaced defrost cycles within each 24-hour pe-

riod.

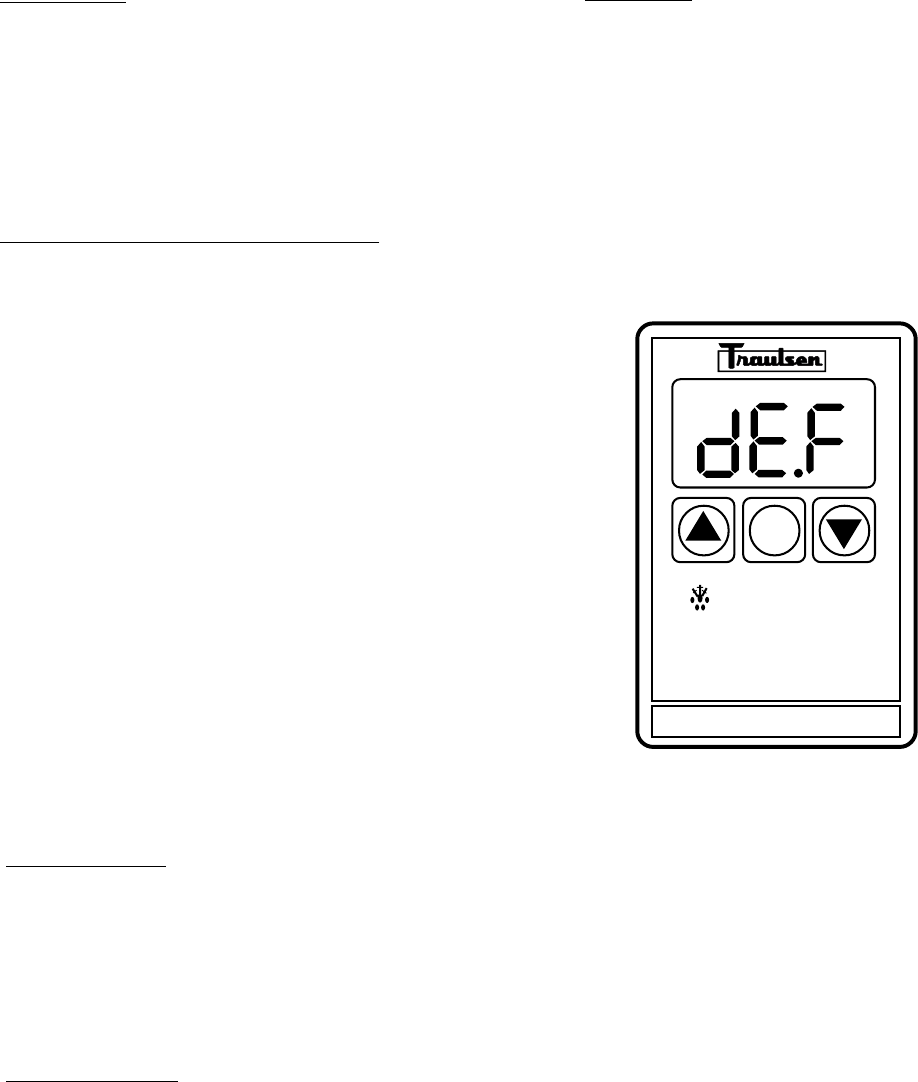

At the start of a freezer defrost cycle, both the com-

pressor and evaporator fans are off. The micropro-

cessor control will read “dEF” (see figure 5).

The electric heater (attached to the coil) is energized.

When a temperature device affixed to the coil senses

70°F (models with electric defrost), the coil is fully de-

frosted and the compressor operation is resumed,

defrost heaters are automatically turned off. The coil

fans are delayed from starting at the termination of a

defrost cycle. Fan operation is automatically resumed,

or they can also be started by a time or temp delay

(whichever comes first). In case of temp delay, it uses

the same coil sensor and starts at 32°F. The total re-

frigeration system operation is then resumed. Dur-

ing freezer defrost operation, heat is confined to the

coil enclosure to prevent any significant rise in tem-

perature within the food zone. The fan delay controls

function upon termination of a defrost cycle is two-

fold. First, to prevent blowing warm air into the food

storage area. Second, to prevent any condensation

on the defrost coil from being blown into the food stor-

age area.

The microprocessor control is set from the factory to

terminate defrost at 20 minutes in the event of a sen-

sor failure. This setting should never be tampered

with, without first consulting the factory.

IV. a - REFRIGERATORS:

Both refrigerators and freezers do not require manual

defrosting. During normal operation, a refrigerator

continuously circulates above freezing cabinet air

through the coil. A compressor “OFF” cycle occurs

every hour to melt any frost which may accumulate on

the coil during the compressor “ON” cycle. The con-

trol will read “dEF” when this occurs. With standard

holding refrigerators, high relative humidity is also

maintained to prevent dehydration of stored product.

-4-

III. i - CLEARANCE:

In order to assure optimum performance, the condens-

ing unit of your Traulsen unit MUST have an adequate

supply of air for cooling purposes. Therefore, the

operating location must either have a minimum of 12”

clearance overhead of the condensing unit or allow

for unrestricted air flow at the back of the unit. Clear-

ance of at least 12” above is required in order to per-

form certain maintenance tasks.

III. j - INSTALLING OPTIONAL INTERIOR KITS:

In addition to their standard interiors, G-Express mod-

els also offer the option for additional shelves or tray

slides. If ordered, these are shipped as kits along with

the unit, packaged in a separate cardboard box which

contains all the necessary parts and hardware for on-

site installation.

To install additional shelves, first remove the white

plastic covers from inside the cabinet. These are lo-

cated along the same vertical line as the pins already

in place on the interior side walls, back and center

mullion (two and three-section models). This exposes

threaded holes in which you may position the new

shelves. Next insert the gray plastic shelf pins into

these holes and tighten by turning clockwise with your

fingers. After all four pins are in place, the new shelf

should be placed to rest on top of them. The unused

plastic covers may be discarded or saved for future

changes to the cabinet interior.

Installation of optional tray slides varies with each

cabinet, and with each type of tray slide ordered. To

install optional tray slides, follow the directions pack-

aged inside the kit carton.

III. k - ON/OFF SWITCH:

An ON/OFF toggle switch for the power supply is pro-

vided. It is located on top of the unit, mounted to the

side of the evaporator housing. This is shipped from

the factory in the ON position.

III. INSTALLATION (continued)

IV. OPERATION

IV. OPERATION (continued)

Fig. 5

°F °C

FREEZER

SET